Mechanism for shaping and boxing glove

A technology of gloves and push plates, applied in the field of machinery and equipment, can solve the problems of inability to realize fully automatic assembly line operation of glove packaging and boxing, inability to reshape the glove side, unfavorable glove boxing, etc., so as to achieve large operation options and boxing High efficiency and good shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

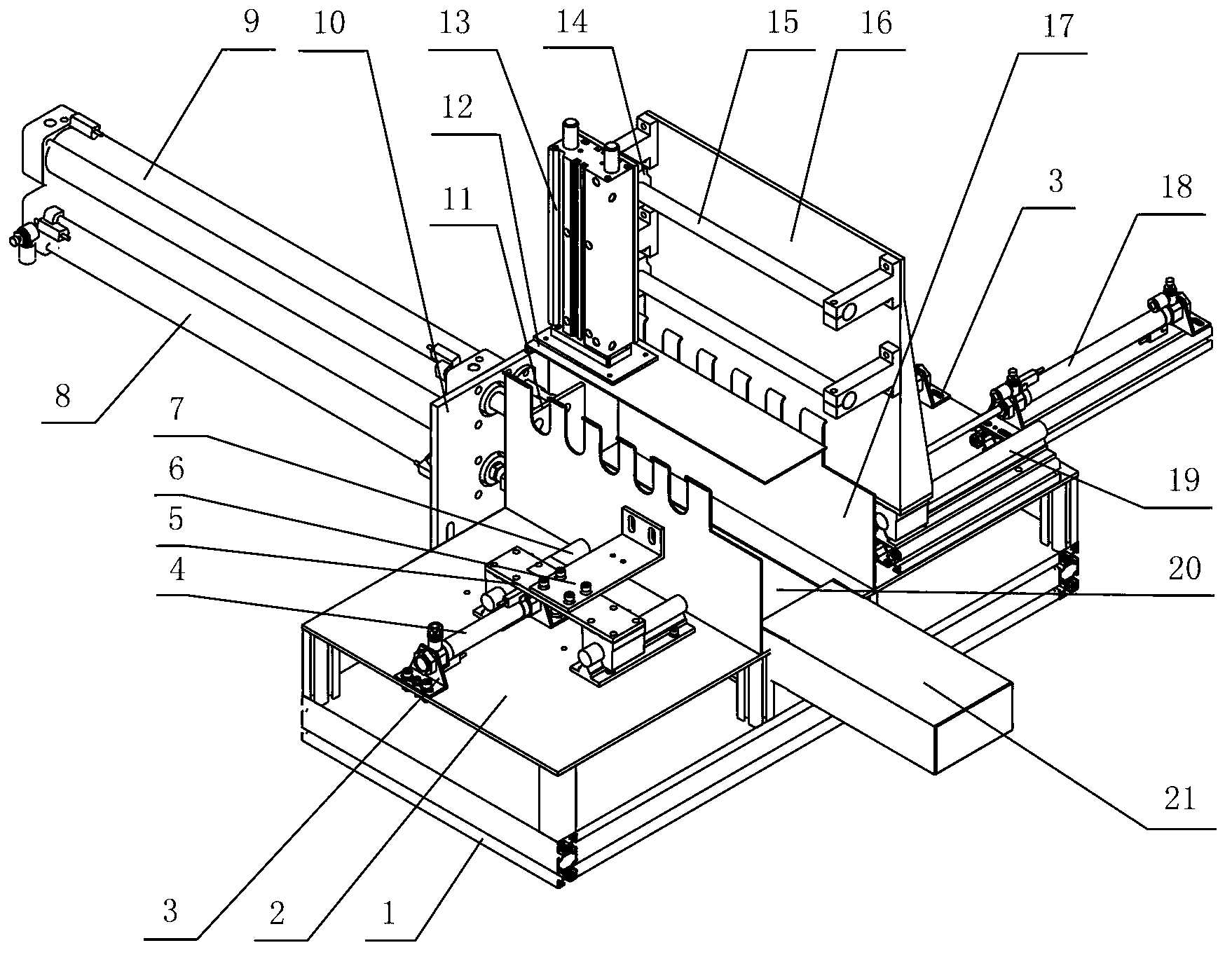

[0031] Such as figure 1 , figure 2As shown, the installation platform is fixed on the base 1, and the glove placement plate 20 is embedded in the middle of the installation platform 2, and is slidingly connected with the installation platform 2. Its cross section is U-shaped, with a groove in the middle, and both ends are flush with the installation platform 2 , the lateral compression plates 17 are arranged symmetrically on both sides of the glove placement plate 20, and the lateral compression plates 17 are movably arranged on the installation platform 2. The upper ends of the lateral compression plates 17 are provided with tooth-shaped gaps, and the upper edge is an everted arc. 17 is fixedly connected with the front end of the transverse drive cylinder 4 through the transverse top plate 6 fixedly connected with it, and the front end of the transverse drive cylinder 4 is fixed at the same time with the connecting plate 5, the connecting plate 5 is perpendicular to the axis...

Embodiment 2

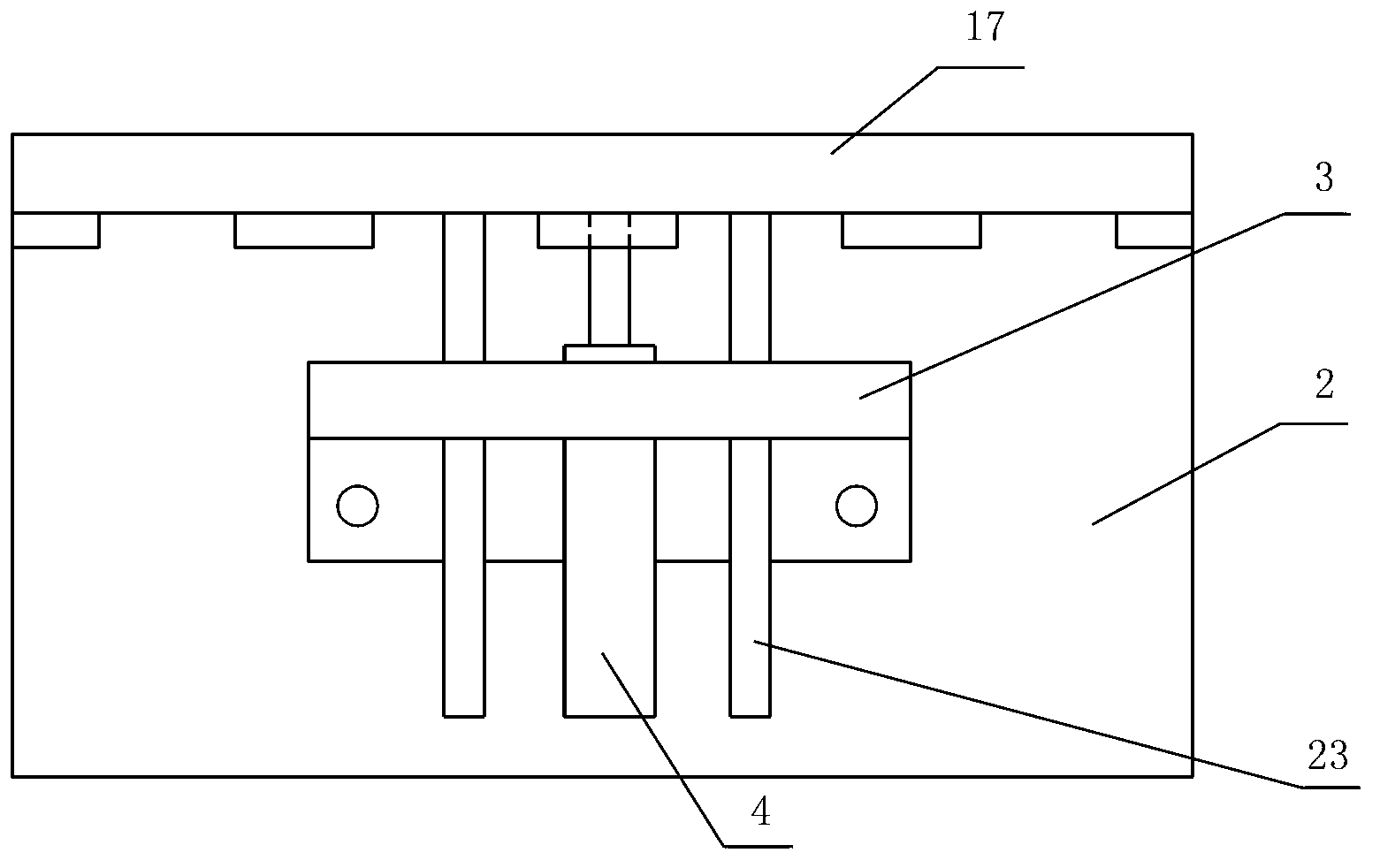

[0034] Such as image 3 As shown, the transverse compression plate 17 is fixedly connected to the front end of the transverse drive cylinder 4, the transverse drive cylinder 4 is fixed on the installation platform 2 through the mounting seat 3, and guide rods 23 are respectively arranged on both sides to make the transverse compression plate 17 move stably, and the guide rod 23 Integrated control with lateral drive cylinder.

Embodiment 3

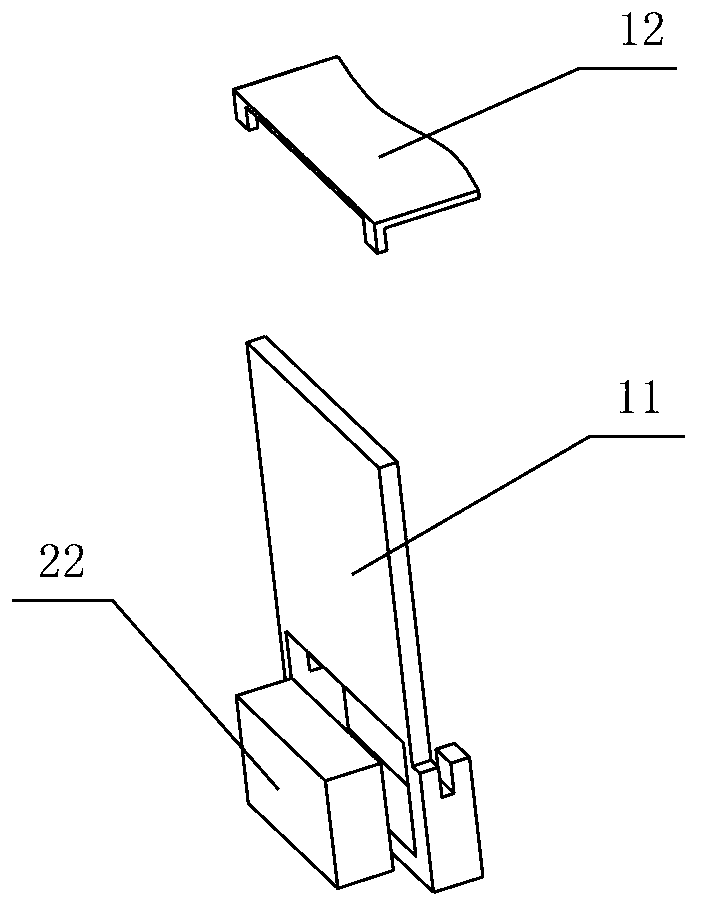

[0036] Such as Figure 4 As shown, the vertical push plate 12 is provided with a folding ear corresponding to one end of the longitudinal push plate 11, and a special-shaped hole is arranged on the fold ear. The special-shaped hole is a long hole, and one end is circular. The front end of the cylinder 9 passes through the longitudinal push plate 11 and cooperates with the shaped hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com