Crawler chassis and crawler cranes

A crawler chassis and crawler frame technology, which is applied to cranes, crawler vehicles, motor vehicles, etc., can solve problems such as wear and tear, and the track frame a1 cannot be repaired, and achieve the effect of avoiding wear and suppressing the phenomenon of tooth gnawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

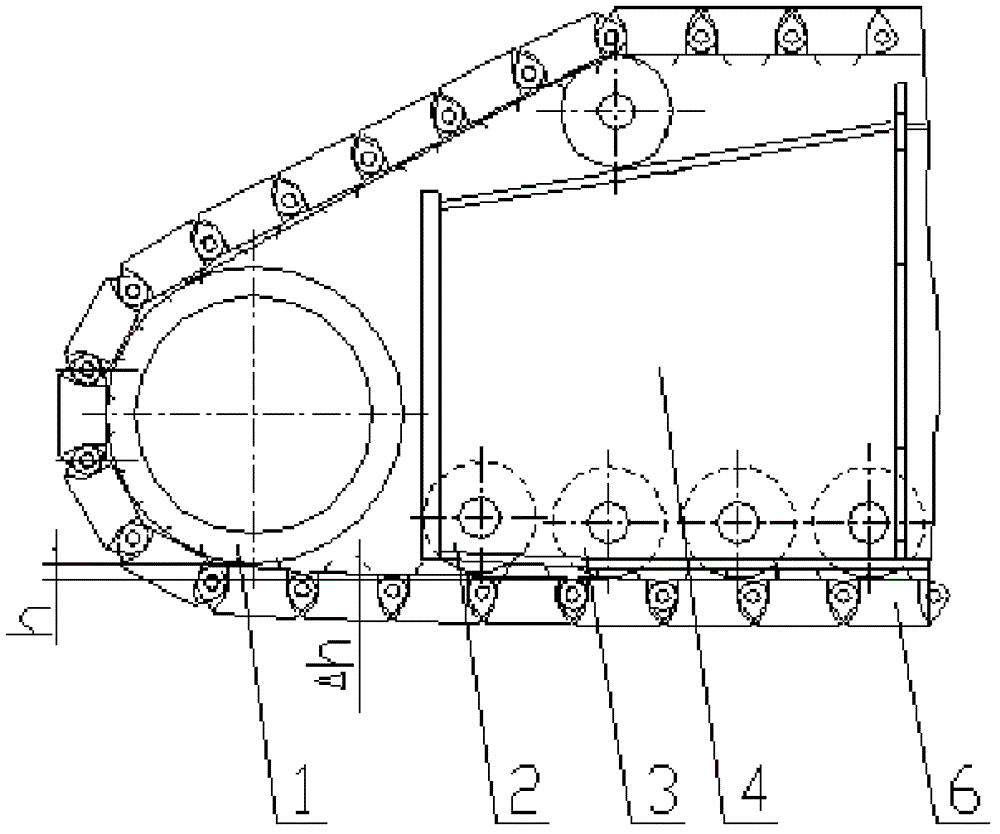

[0028] In the present invention, considering that the original fixed pressure plate cannot rotate or roll with the movement of the crawler shoe, it will produce rigid sliding friction with the crawler shoe, resulting in the crawler shoe and the crawler frame welded with the fixed pressure plate. Serious wear and tear that cannot be repaired. Therefore, in the present invention, the structure that the pressure plate cannot rotate or roll with the movement of the track shoe is changed, and the rolling friction structure that can rotate or roll is used to replace the existing fixed pressure plate.

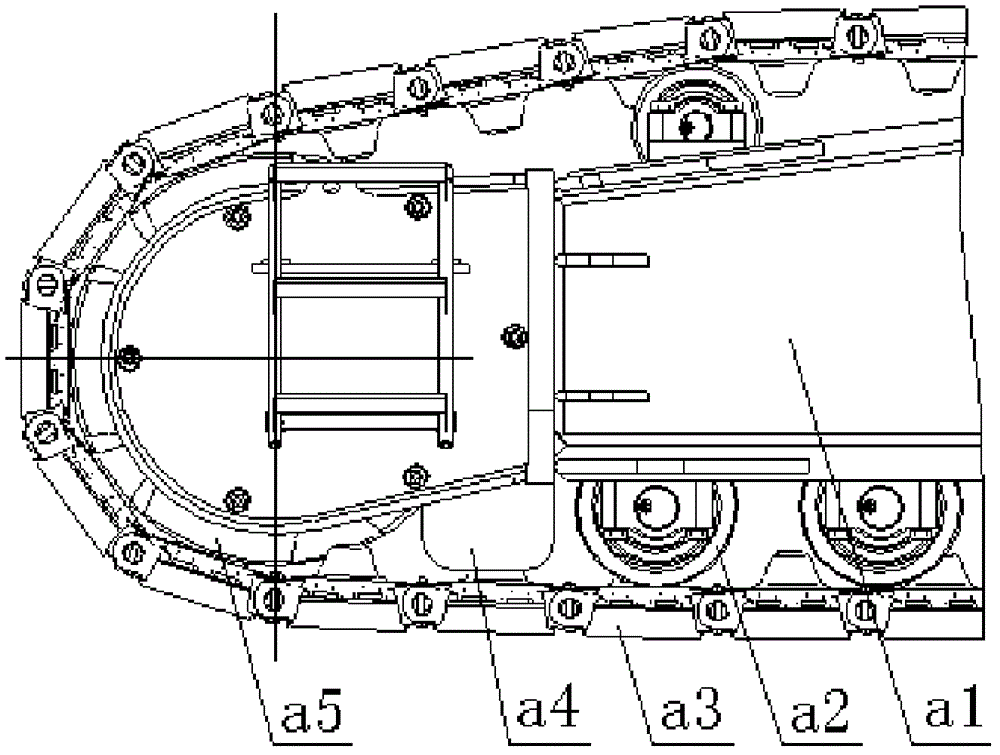

[0029] In an embodiment of the present invention, the crawler chassis includes a crawler frame, a driving wheel installed at the end of the crawler frame, a plurality of rollers installed at the bottom of the crawler frame, and surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com