Base of relay

A relay and bottom surface technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of short creepage distance of wiring pins, poor heat dissipation effect of outer bottom surface, low safety factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

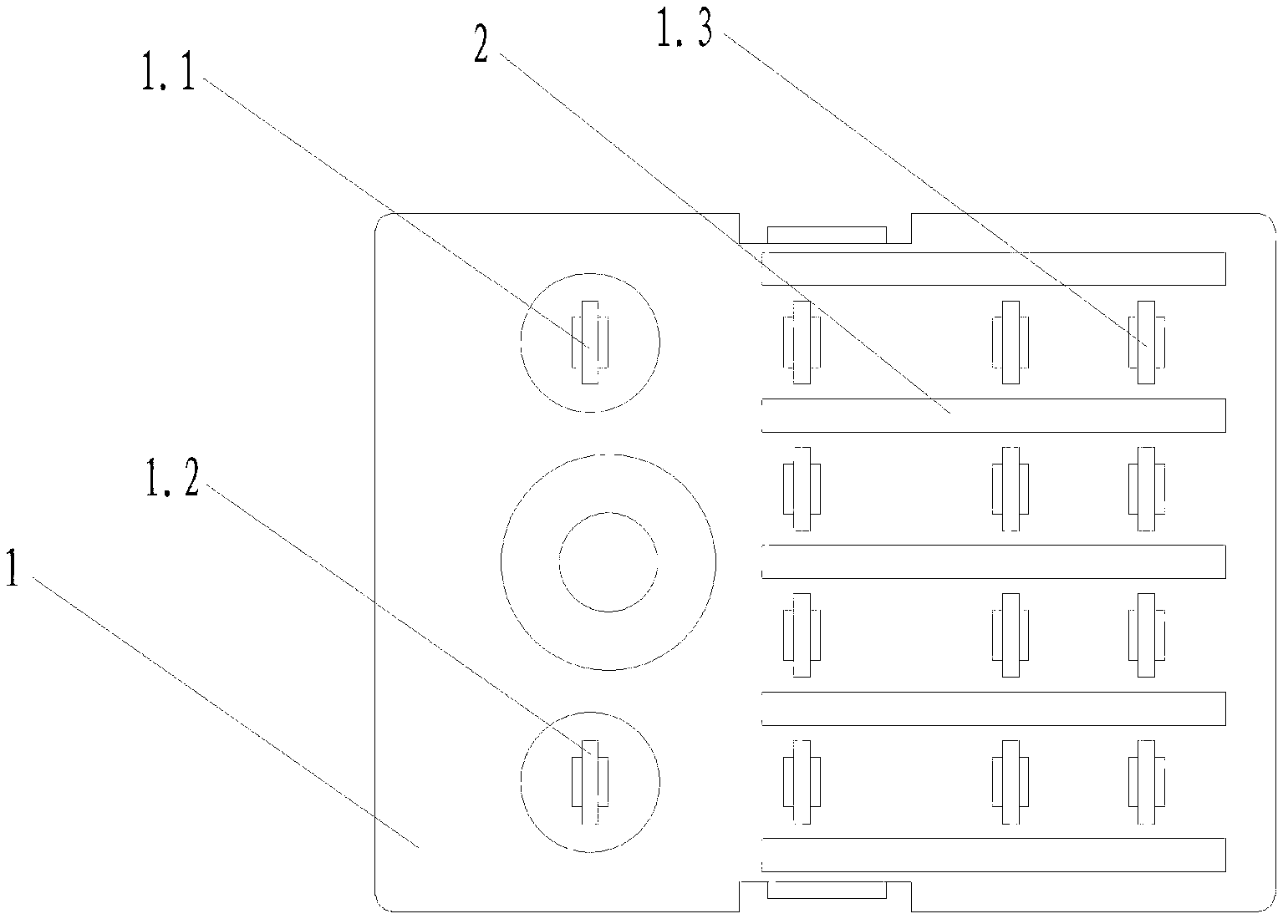

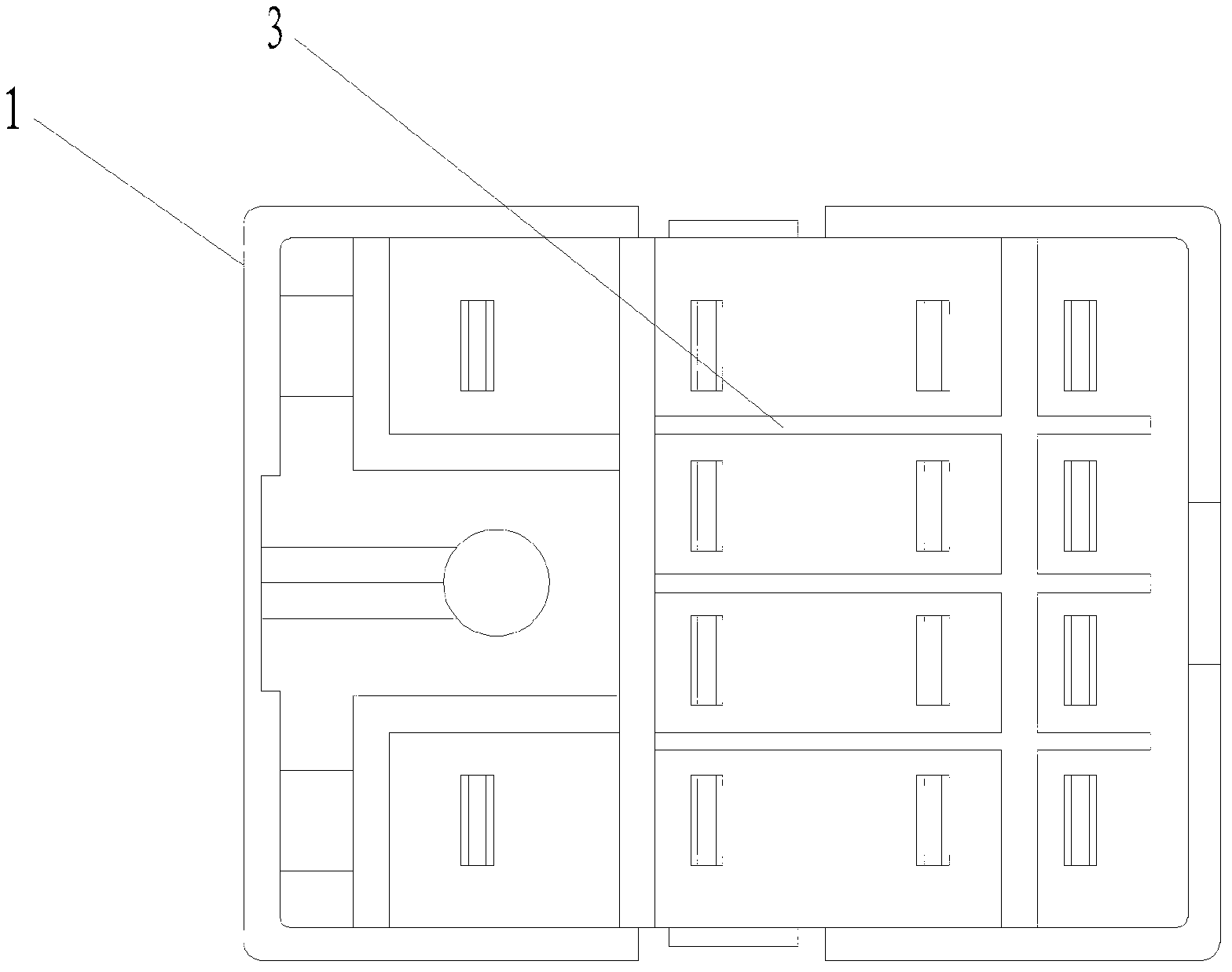

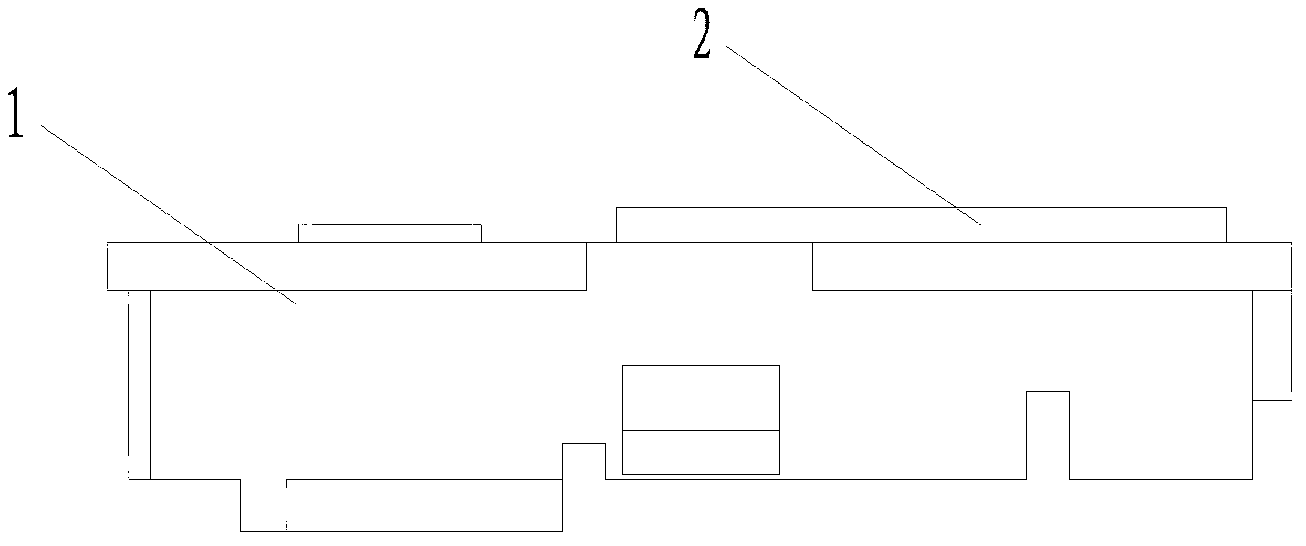

[0014] Such as figure 1 , figure 2 , image 3 As shown, the base of the relay of the present invention includes a base body 1, and the base body 1 is provided with a first mounting hole 1.1 and a second mounting hole 1.2 for installing a coil terminal pin and a plurality of first mounting holes for installing a moving spring and a static spring. Three through holes 1.3, the number of the third through holes 1.3 is twelve, distributed in four rows, three in each row; the two sides of the third through holes 1.3 in each row on the outer bottom surface of the base body 1 are One spacer 2 is provided, so that the total number of spacer 2 is 5, and the spacer 2 is integrally formed with the base body 1 .

[0015] The height of the spacer 2 is 1mm.

[0016] A groove 3 is provided between two adjacent rows of third through holes 1.3 on the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com