Dynamic pressure solid-liquid separator

A solid-liquid separator, dynamic excitation technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the difficulty of maintaining a constant vacuum degree with negative pressure difference, it has not been popularized and applied, and the practical effect is not ideal. and other problems, to achieve the effects of less drilling fluid loss, simplified solids control equipment and systems, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

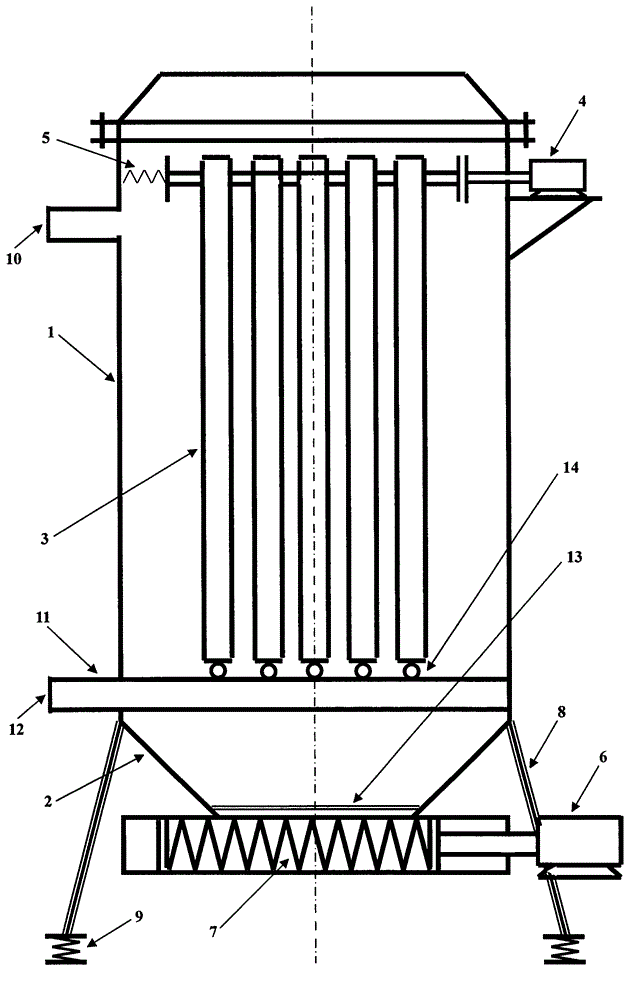

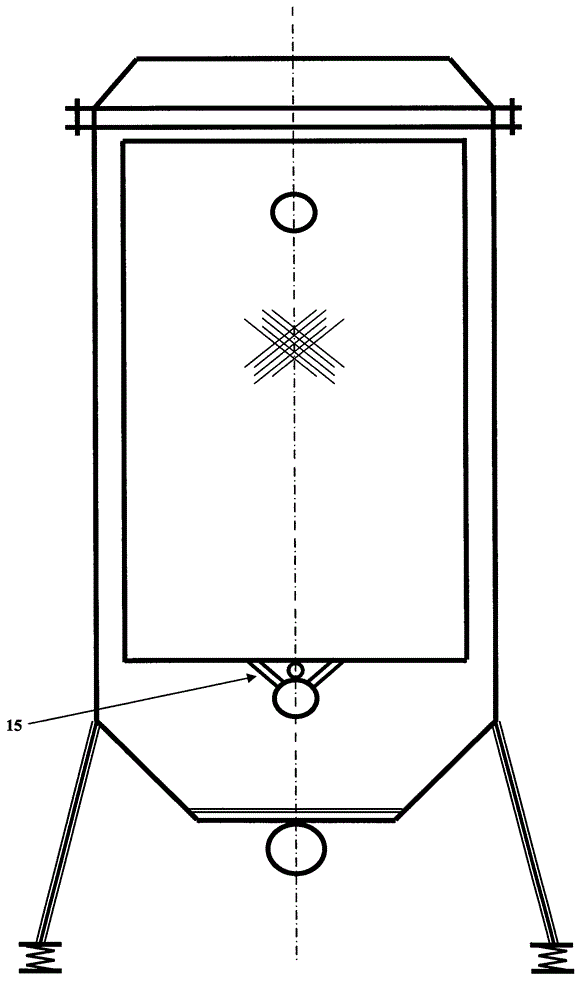

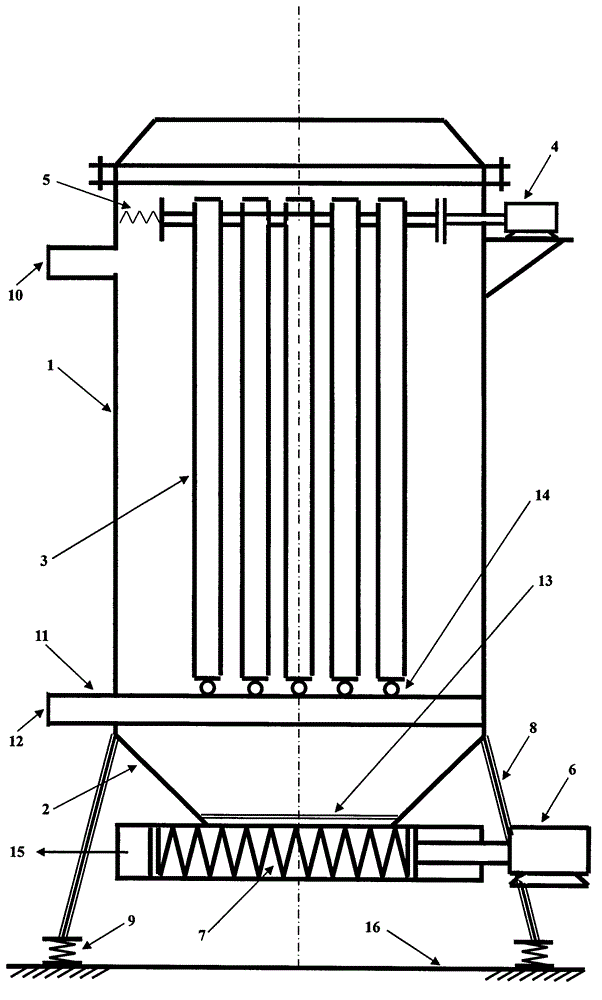

[0031] image 3 It is a schematic diagram of the installation of the embodiment of the dynamic pressure solid-liquid separator of the present invention.

[0032] The complete machine is installed and fixed on the foundation or the mud tank body 16 by the base 8 and the base damping support spring 9 .

[0033] The raw mud slurry containing solid phase and liquid phase enters the cubic pressurized mud box 1 from the inlet 10, and the separated liquid phase (containing solid phase particles that are allowed to retain the specified particle size range) is discharged from the mud outlet 12 to the liquid phase mud The collection device, the solid particles that need to be removed are compacted by the chip compactor 7 of the screw chip removal mechanism, and then discharged from the outlet 15 of the chip compactor 7 to a special solid particle collection box for subsequent processing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap