A flip casting method for 30f loader axle housing

A loader and axle housing technology, which is applied in the field of overturn casting of 30F loader axle housing, can solve the problems of heavy welding workload, difficulty in matching the main parts of the axle housing accurately, and many casting processes, etc., and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, a method for overturning the axle housing of a 30F loader, including the following steps:

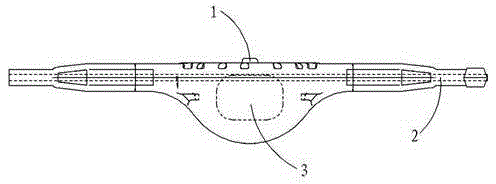

[0021] (1), the production of sand core, such as figure 1 As shown, the threaded steel with a diameter of 20mm is used as the core bone 2 of the sand core to enhance the central strength of the sand core; foam 3 is filled inside the bridge bag to reduce the weight of the sand core; and the center of the flange surface is opened A flange core head seat 1 with a diameter of 50 mm is produced, and the flange core head seat 1 is embedded with a metal iron wire and bound to the core bone 2 .

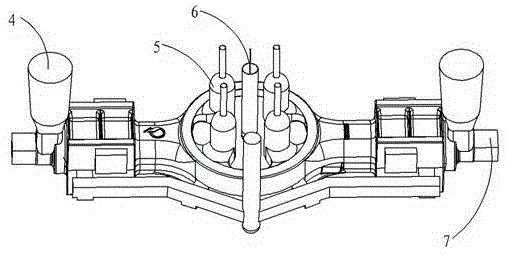

[0022] (2), the manufacture of the upper mold cavity, such as figure 2 As shown, a heating riser 4 is provided at both ends of the upper mold, and four heating dark risers 5 are provided on the edge of the flange surface in the middle of the upper mold along the circumferential direction. Out of a diameter of 50mm hanging sand core channel 6.

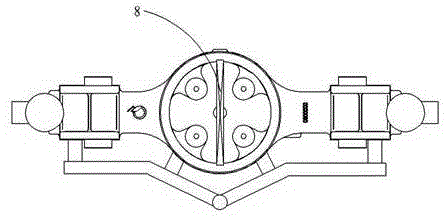

[0023] (3), such as image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com