Patents

Literature

36results about How to "No trachoma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe and manufacturing method thereof

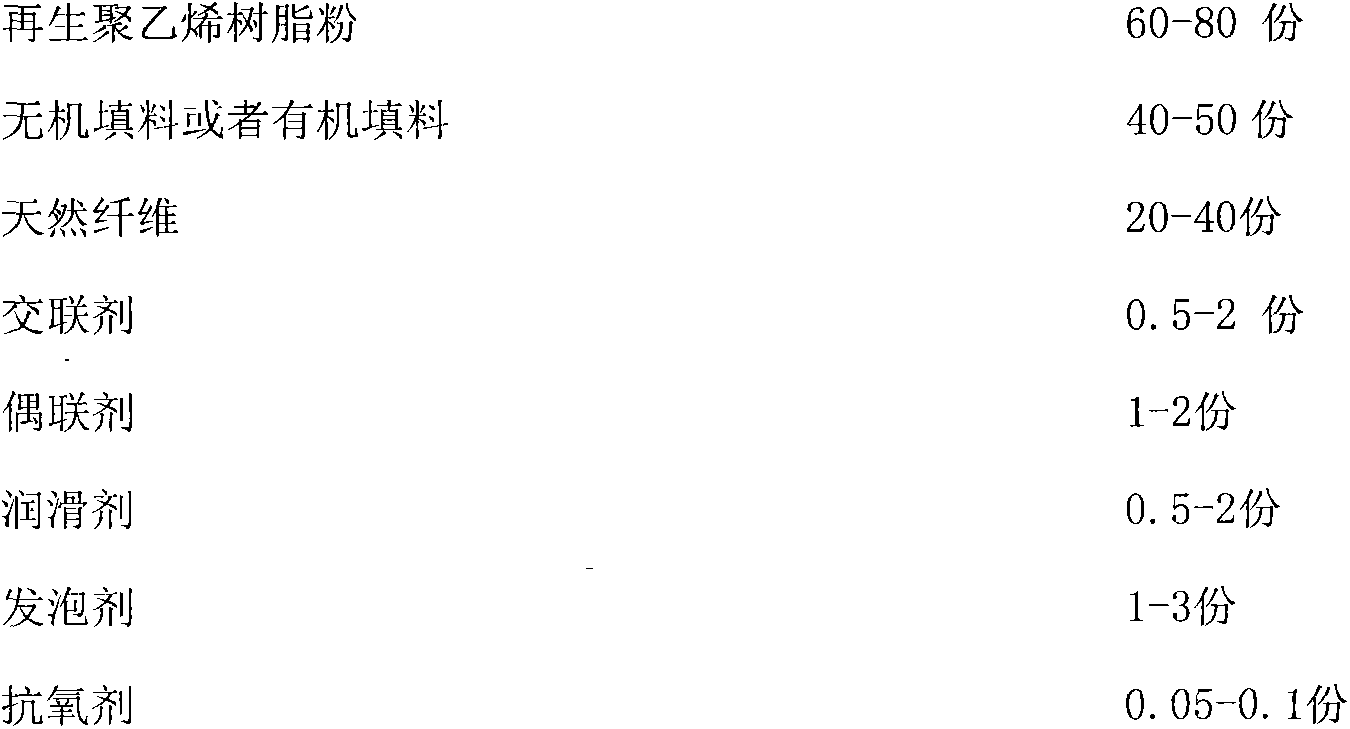

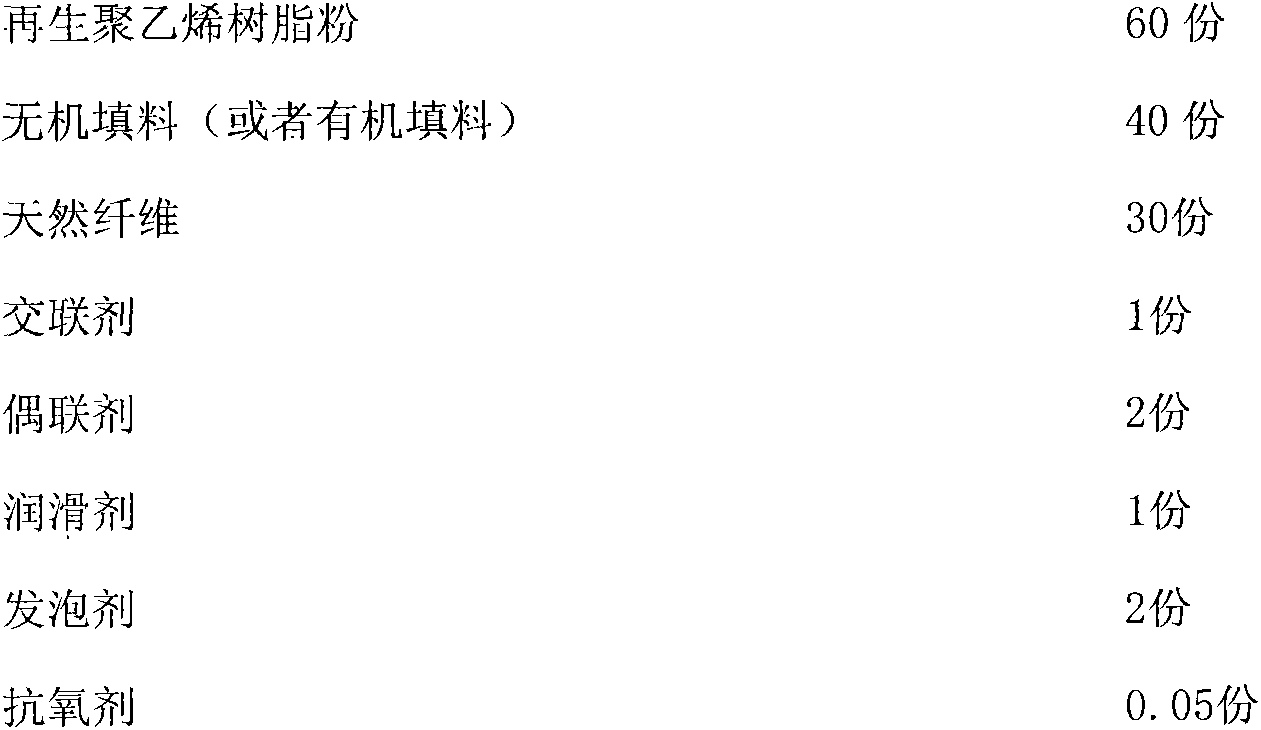

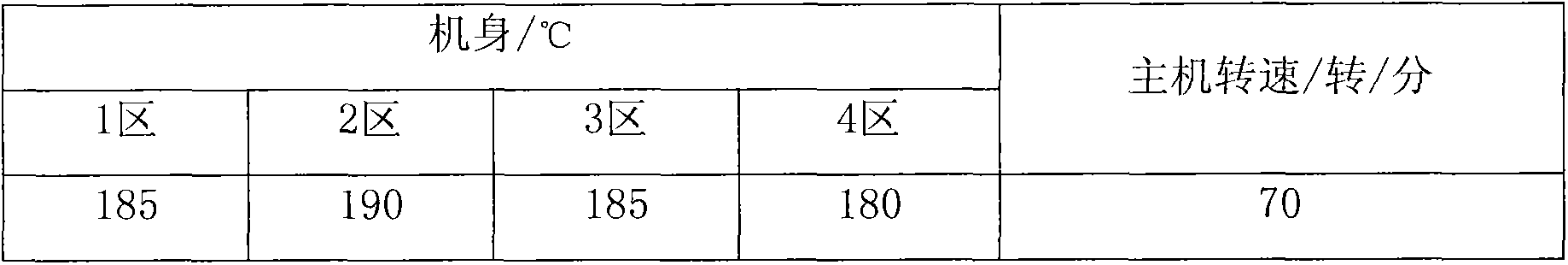

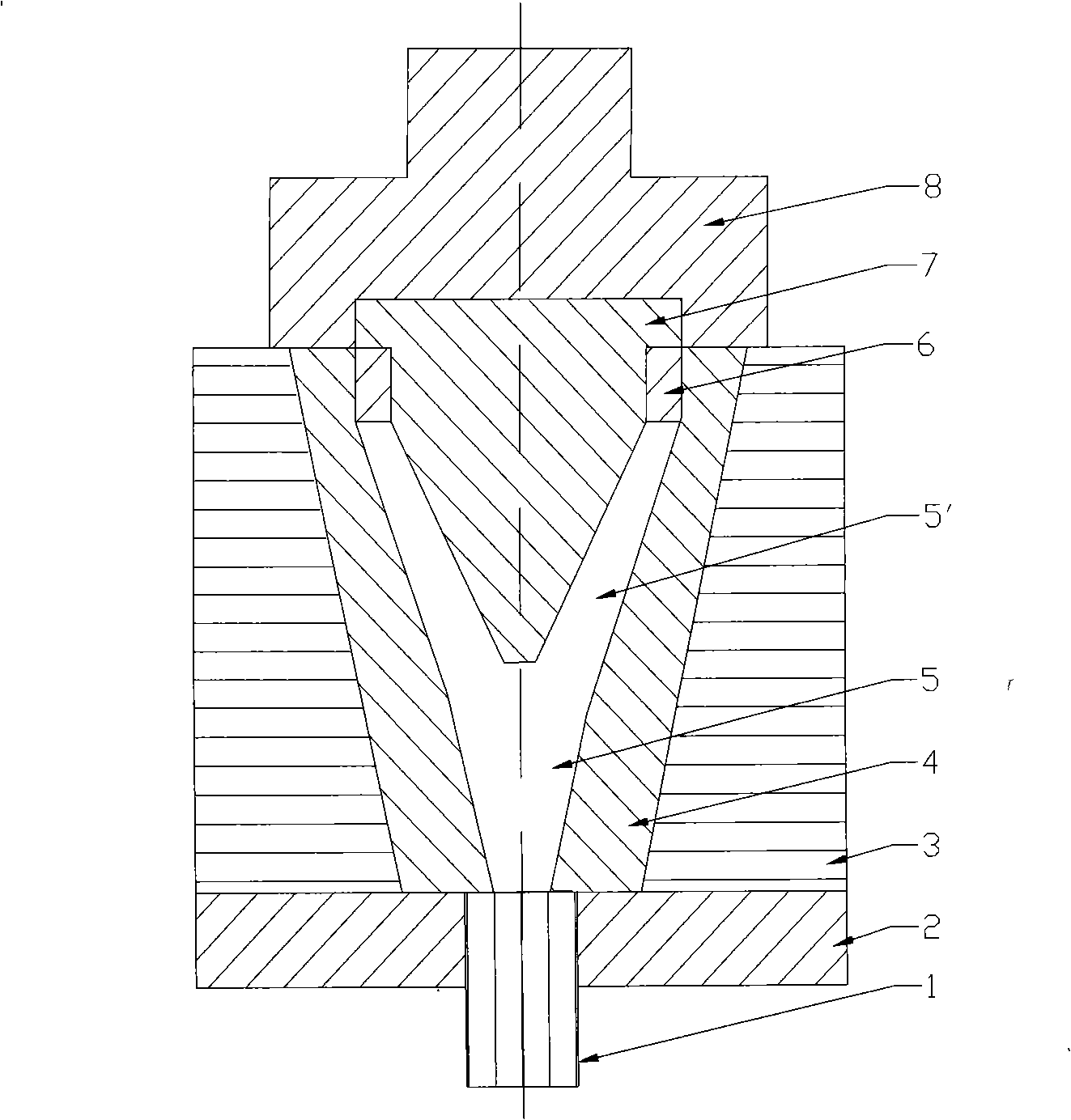

The invention belongs to the field of pipes, relates to an enhanced drainage pipe and mainly relates to a superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe which is suitable for wastewater discharging, engineering transforming projects and home decoration of villa communities, high-rise residential communities, high-grade residential apartment communities and the like and industrial building fields like water discharging, sewage discharging, waste discharging and the like of industrial enterprises. The superstrong-muting PE composite drainage pipe is a multilayer composite body formed by a high-density polyethylene resin inner layer, a middle PE micro-foamed layer and a high-density polyethylene resin outer layer, the thickness ratio of the inner layer, the middle layer and the outer layer is 1:4:1, and the PE micro-foamed layer is composed of regenerated polyethylene resin powder, inorganic filler or organic filler, natural fibers, a cross-linking agent, a coupling agent, a lubricating agent, a foaming agent and an antioxidant. The superstrong-muting PE core layer micro-foamed drainage pipe has excellent denoising and muting performance, superstrong resistance to chemical corrosion and good impact resistance.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

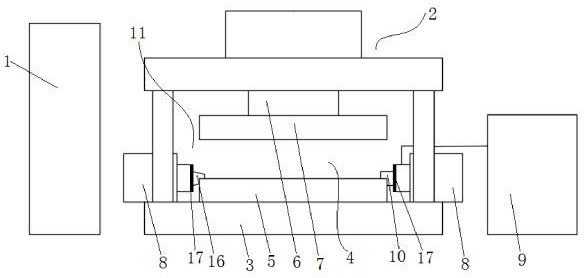

Split type die for press machine, manufacturing method and forging cutting teeth thereof

InactiveCN101408030AHigh dimensional accuracyIncrease productivitySoil-shifting machines/dredgersForging/hammering/pressing machinesEngineeringMechanical property

The invention discloses a split type mould used for a press, a manufacturing method and a forging bucket tooth thereof, which utilizes the split type mould to solve the technical problem of demoulding. The adopted mould is divided into an upper separated body and a lower separated body, the upper separated body consists of a punch head upper cover and a punch head embedded at the lower end of the punch head upper cover; the lower separated body is formed by that an outer sleeve is fixedly connected on a backing plate and internally installed with a tube mold of the separated body, and a disconnecting square sleeve is installed at the upper part inside the tube mold; and an ejector rod is installed in the central hole of the backing plate. The manufacturing method comprises the following steps: the punch head is utilized for hammering the blank so as to carry out foring compression in the tube mold, the punch head moves upwards when the press returns to the original position, the disconnecting square sleeve prevents the forging bucket tooth form moving so as to disconnect the punch head and the forging bucket tooth, the ejector rod ejects the forging bucket tooth and the tube mold of the separated body upwards, the tube mold is divided into two blocks along the outer sleeve, and the forging bucket tooth carries out demoulding automatically. The invention solves the problem of the automatic demoulding of the bucket tooth by foring compression; the mechanical property and the wear-resisting property of the forging bucket tooth are improved by more than 30 percent compared with that of a casting bucket tooth, especially when being used in severe conditions such as mines and the like, the forging bucket tooth has more superior performances.

Owner:陈宏毅

Method for processing shell of industrial plug socket

InactiveCN101577394AWide range of choicesLow priceContact member cases/bases manufactureCorrosionMachining process

Owner:李贵阳

High-strength alcohol-based casting coating and manufacturing method thereof

InactiveCN104226892AUniform coatingImprove the level ofFoundry mouldsFoundry coresPolyvinyl alcoholTemperature resistance

The invention discloses a high-strength alcohol-based casting coating. The high-strength alcohol-based casting coating is characterized by comprising the following materials in parts by weight: 75-90 parts of quartz ceramic powder, 20-30 parts of coal ash, 1-2 parts of sodium-based bentonite, 3-5 parts of water glass, 4.2-6.3 parts of mineral wool, 0.5-0.8 part of NAST flame-retardant agent, 15-18 parts of cotton stalk, 0.3-0.6 part of dicumyl peroxide, 5-8 parts of polyvinyl butyral, 55-65 parts of alcohol and 3-6 parts of additive. The high-strength alcohol-based casting coating disclosed by the invention has the advantages of high strength, good suspension property, uniform coating layer, good leveling property, high-temperature resistance and strong air permeability and the like; and after the coating is dried, the surface is smooth and clean without sand holes, bubbles and cracks.

Owner:WUHU HONGKUN AUTO PARTS

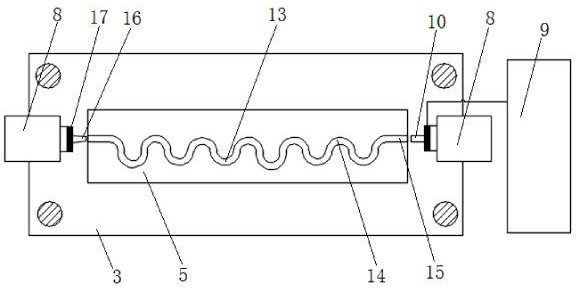

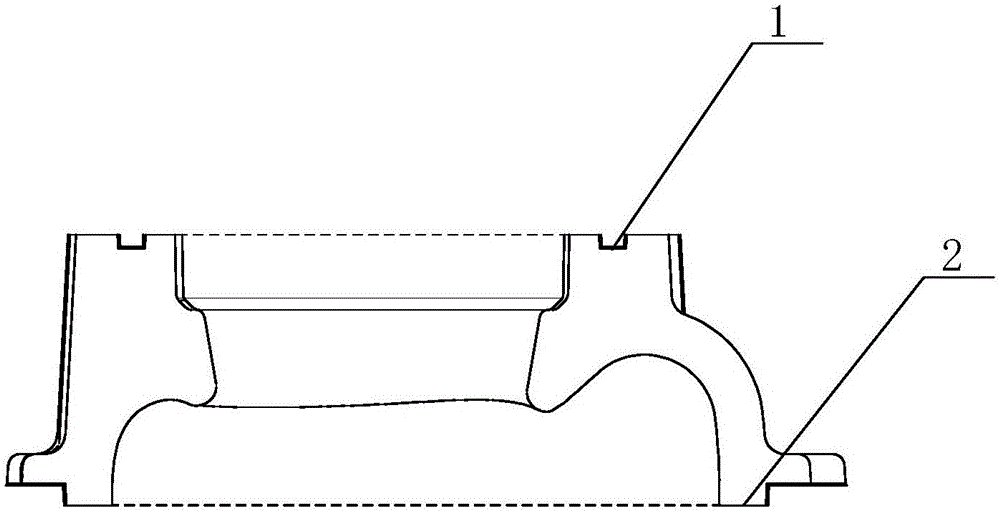

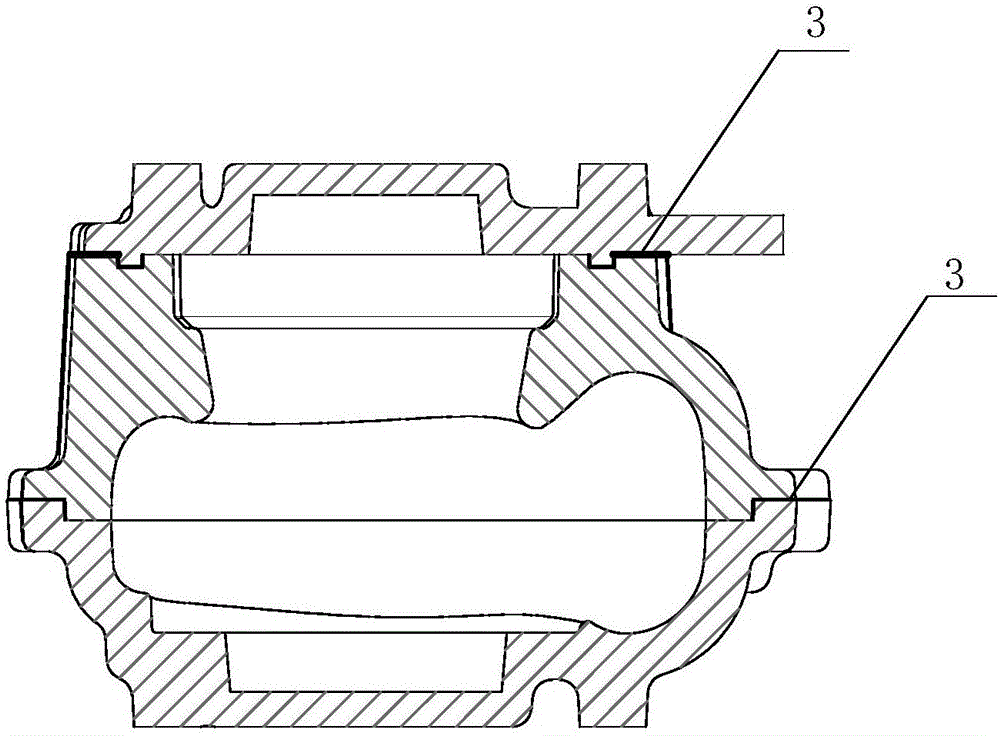

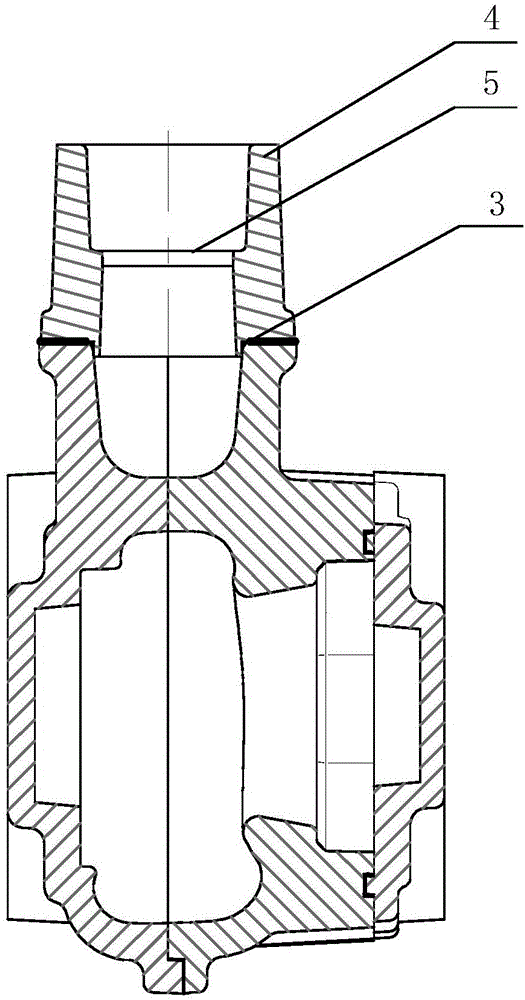

Water expansion forming process for vehicle universal joints

ActiveCN108838270AImprove surface appearance qualityIncrease productivityUniversal jointPore water pressure

The invention discloses a water expansion forming process for vehicle universal joints. The process is characterized by comprising the following steps: (1) raw materials-carbon steel pipes are cut asneeded sizes; and burrs at two ends are removed; (2) the carbon steel pipes are annealed at a temperature of 450-600 DEG C to reach the surface hardness HRB of 30-40; (3) the carbon steel pipes are put in a water expansion mold; the mold is tightly pressed by a water expansion machine; meanwhile, booster cylinders at two ends are pushed into punches; saponification liquid with pressure of 16 MPa is injected for primary water expansion formation; the water expansion forming parameters are as follows: the water expansion machine applies the pressure of 120 tonnages to a main cylinder; the pressure is lower than 24 MPa; the output pressure is higher than 18 MPa; the output water pressure of left and right side cylinders is 20-28 MPa; the displacements of the left and right punches are 43 mm;the water cylinder capacity is higher than 1.5 L; and the water supply pressure is lower than 4 MPa; and (4) semi-finished products are annealed again after water expansion by the procedures; the annealing temperature is 450-600 DEG C; and the hardness HRB is 34-36.

Owner:广东思豪内高压科技有限公司

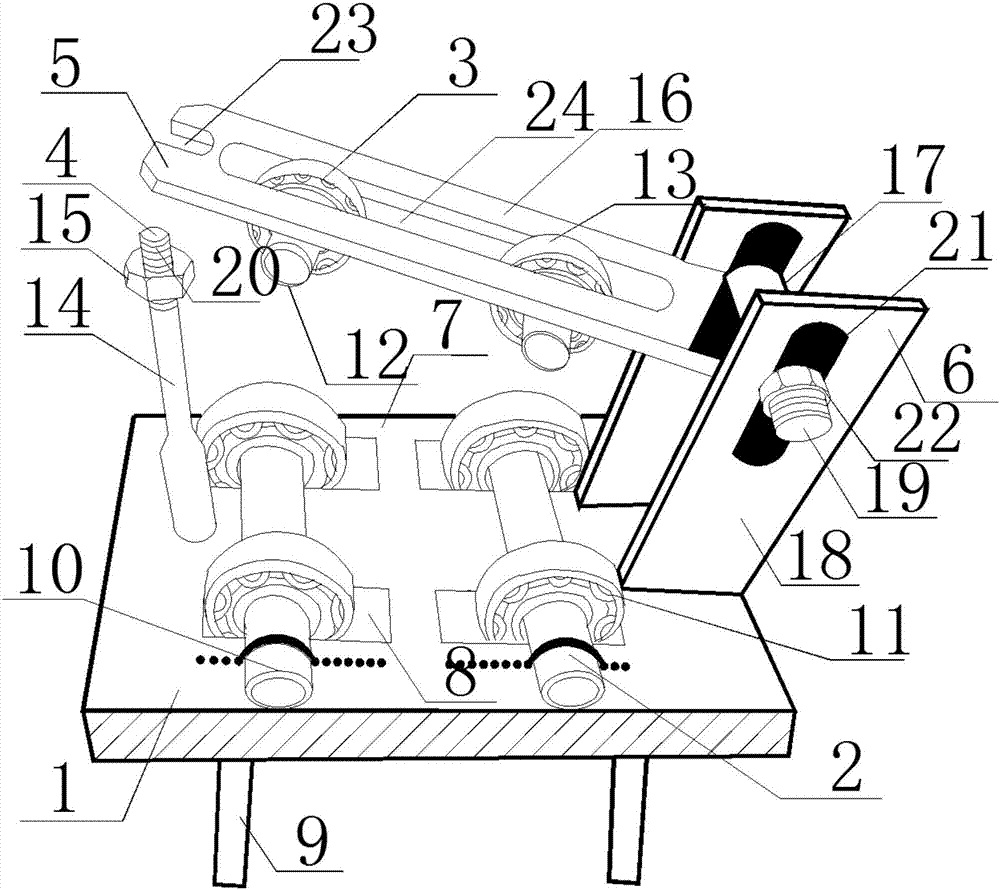

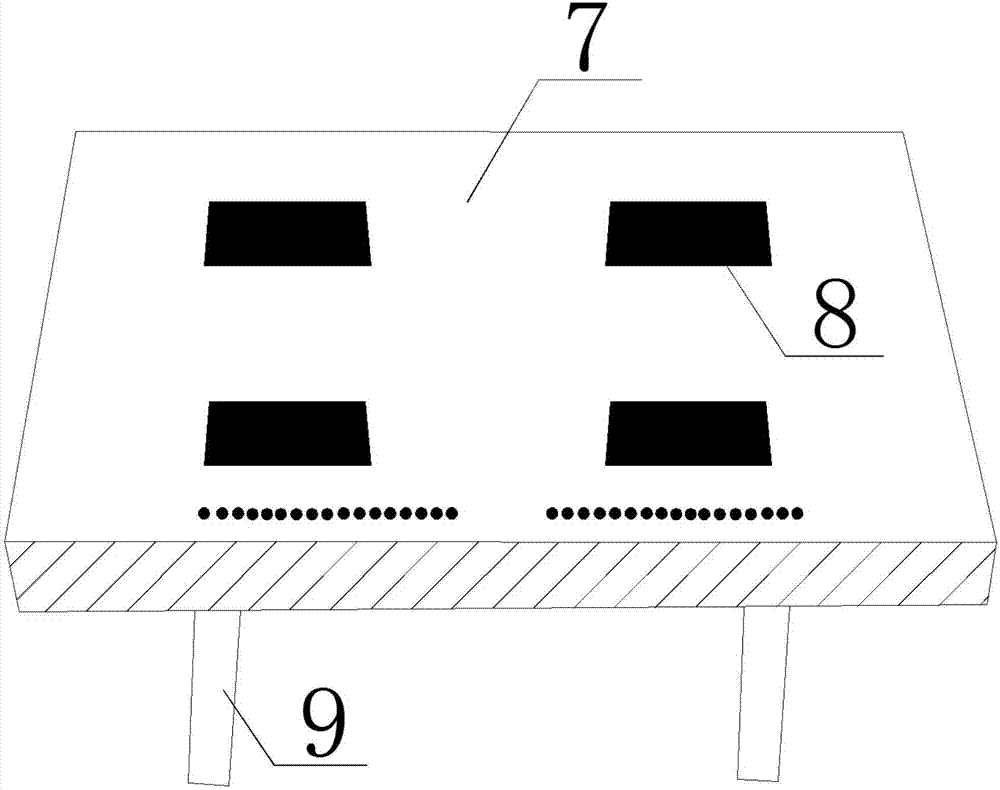

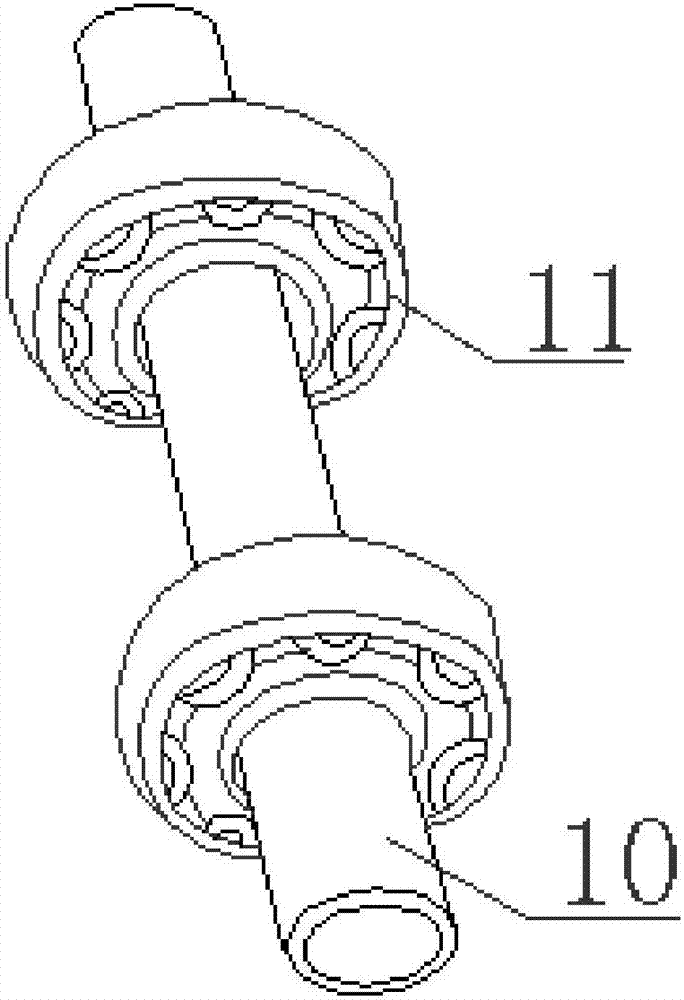

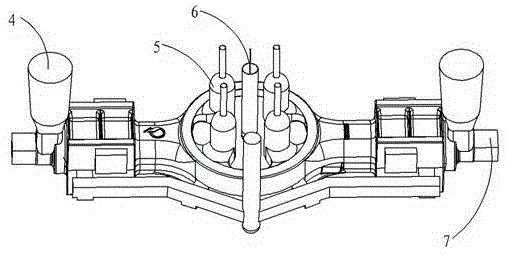

Fixing tool for fire hydrant connecting elbow welding

ActiveCN106975890ASimple structureReasonable designWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

Disclosed is a fixing tool for fire hydrant connecting elbow welding. The fixing tool comprises an operating platform, a large transmission shaft mechanism, a small transmission shaft mechanism, a fixing device, a press plate mechanism and an adjustable bolt device. The large transmission shaft mechanism is installed in the middle of the operating platform. The fixing device and the adjustable bolt device are located on the two sides of the large transmission shaft mechanism and fixedly installed on the operating platform. The press plate mechanism is located above the large transmission shaft mechanism, one end of the press plate mechanism is connected with the adjustable bolt device, and the other end of the press plate mechanism interacts with the fixing device. The position of the press plate mechanism relative to the large transmission shaft mechanism is adjusted through the adjustable bolt device and fixed through the fixing device. The small transmission shaft mechanism is located above the large transmission shaft mechanism and installed on the press plate mechanism. The fixing tool effectively solves the problems that fire hydrant connecting elbow welding is low in speed, connector deviation exists, and the quality is poor, improves the working efficiency, saves the manpower and the cost, and protects the environment.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

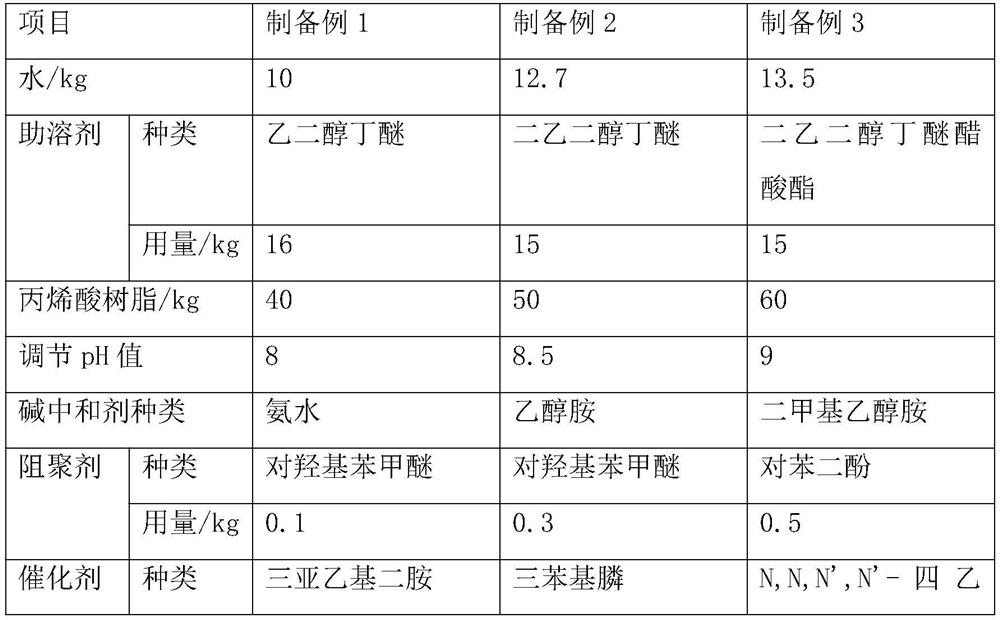

Water-soluble photosensitive ink as well as preparation method and construction method thereof

ActiveCN114350202ANot easy to produce delamination and other phenomenaEvenly dispersedInksPolymer scienceGlycidyl methacrylate

The invention relates to the field of ink, in particular to water-soluble photosensitive ink as well as a preparation method and a construction method thereof. The water-soluble photosensitive ink comprises the following raw materials in percentage by weight: 40-70% of water-based photosensitive resin, 3-6% of a photosensitizer, 4-15% of a photosensitive monomer, 0.3-3% of color-changing light powder, 10-40% of water and the balance of an auxiliary agent, the water-based photosensitive resin is mainly generated by reaction of acrylic resin and glycidyl methacrylate. The water-based photosensitive resin generated by the reaction of the acrylic resin and the glycidyl methacrylate enables the raw material components in the ink to be uniformly dispersed, the phenomena of ink layering and the like are not easy to generate, the flow ductility and the adhesiveness of the ink on a PCB (Printed Circuit Board) are better, and a polymer film formed by ultraviolet irradiation is good in adhesiveness and has a stable protection effect on a copper layer; a copper line formed after developing, etching and deinking is free of sand holes, open circuits, short circuits and other undesirable phenomena.

Owner:LANBANG ELECTRONICS HARDWARE MATERIAL DONGGUAN

An alloy material flange and a machining process

The invention relates to the field of alloy material machining, particularly an alloy material flange and a machining process. The alloy material flange includes following chemical components (by mass): 0.18-0.27% of carbon, 1.4-2.0% of silicon, 0.5-1.2% of manganese, 0.01-0.08% of phosphor, 0.001-0.004% of sulfur, 0.03-0.1% of nickel, 1.1-2.0% of copper, 0.12-0.21% of titanium, 0.65-0.9% of molybdenum, 0.31-0.37% of boron, 5.7-6.2% of aluminium, 0.27-0.3% of chromium, and 23-30% of vanadium, with the balance being iron and unavoidable impurities. The process includes steps of smelting, forging, heat treatment, blank examination, lathe machining, boring and product examination.

Owner:山东瑞烨新能源装备有限公司

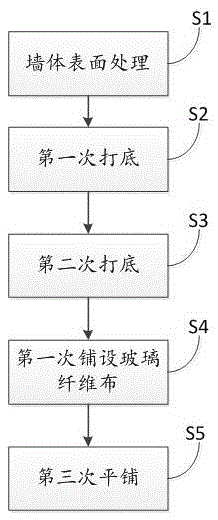

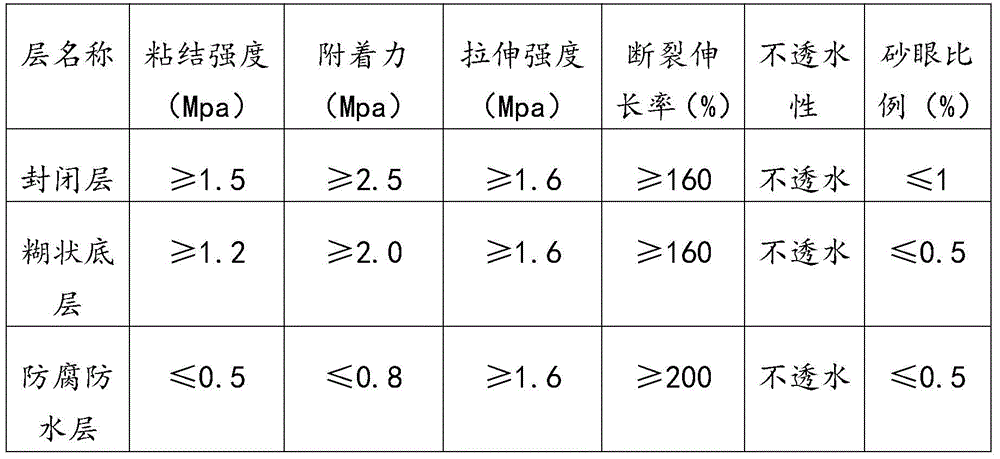

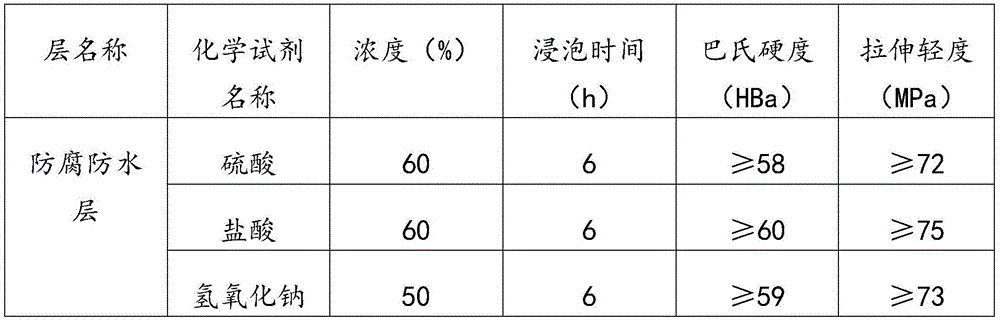

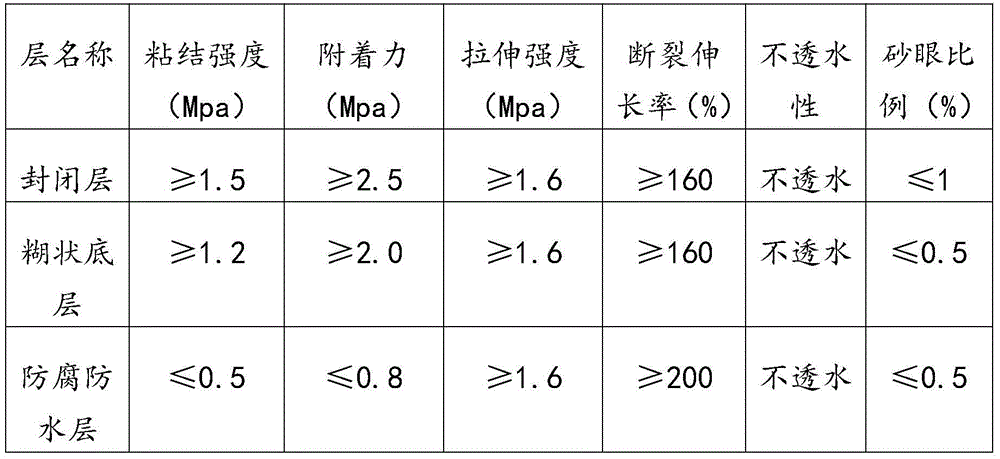

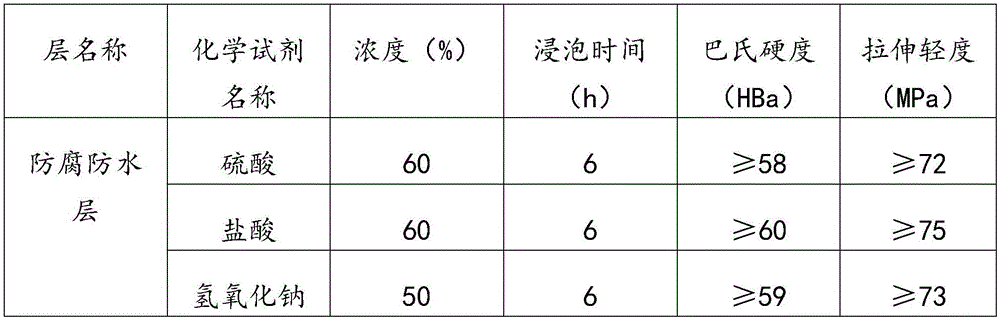

Seamless, corrosion-resistant and waterproof construction process for wall

InactiveCN105484516AFully contactedStrong adhesionBuilding repairsCoatingsCorrosion resistantMaterials science

The invention discloses a seamless, corrosion-resistant and waterproof construction process for a wall. The process comprises the following steps of wall surface treatment, primary bottom preparation, secondary bottom preparation, primary glass fiber cloth laying and third flat laying. According to the seamless, corrosion-resistant and waterproof construction process for the wall, used materials are great in adhesion, and a corrosion-resistant and waterproof surface formed through construction has the advantages of being free of seams, free of sand holes, free of leakage, free of falling, long in service life, flexible in construction and the like. After construction is completed, a tight 'armor suit' can be formed on the construction surface, and acid and alkali prevention, corrosion protection and crack resistance are achieved. By means of the process, the technical difficulty that previous wall corrosion-resistant and waterproof materials fall off easily and are difficult in construction is broken through, the effects of being free of seams, sand holes and falling are achieved in the real sense, the difficult problem that a wall waterproof layer leaks is thoroughly solved, and the domestic blank in the field is filled up.

Owner:王效禹

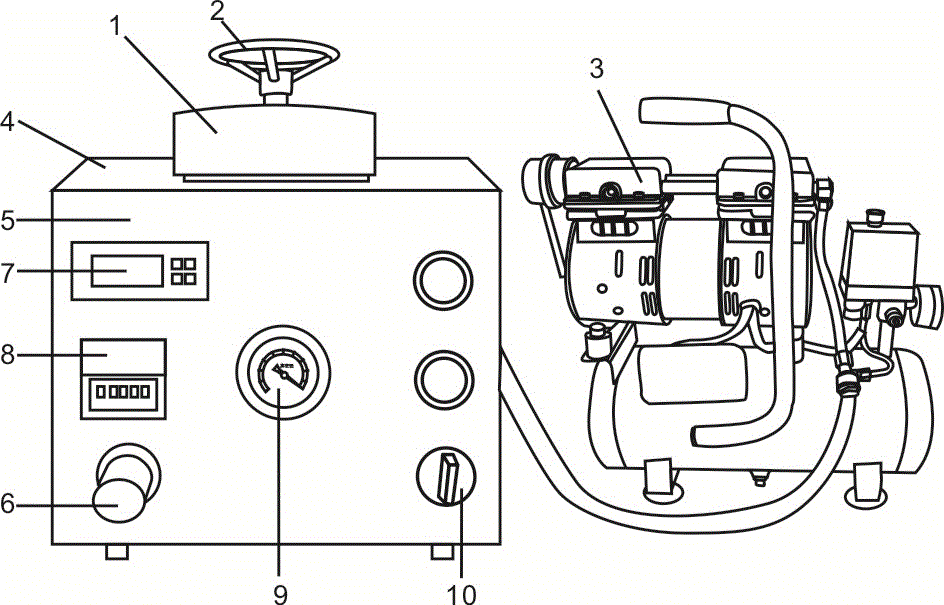

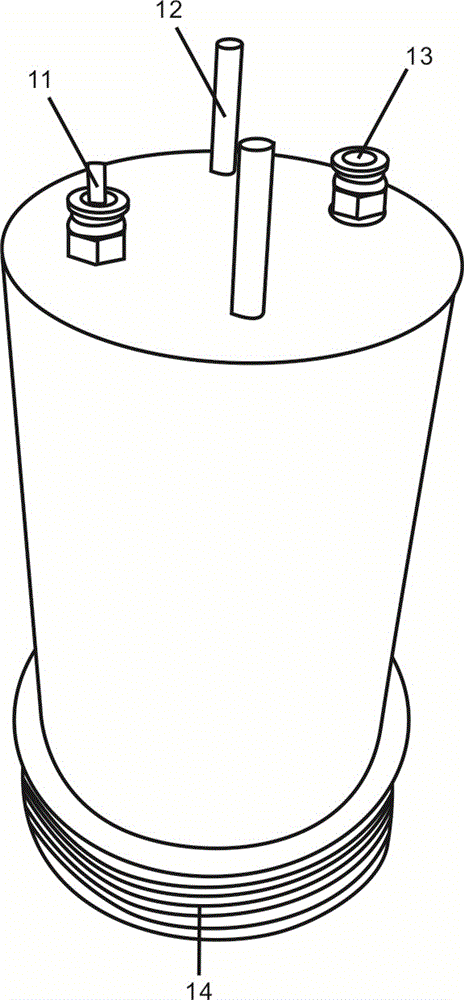

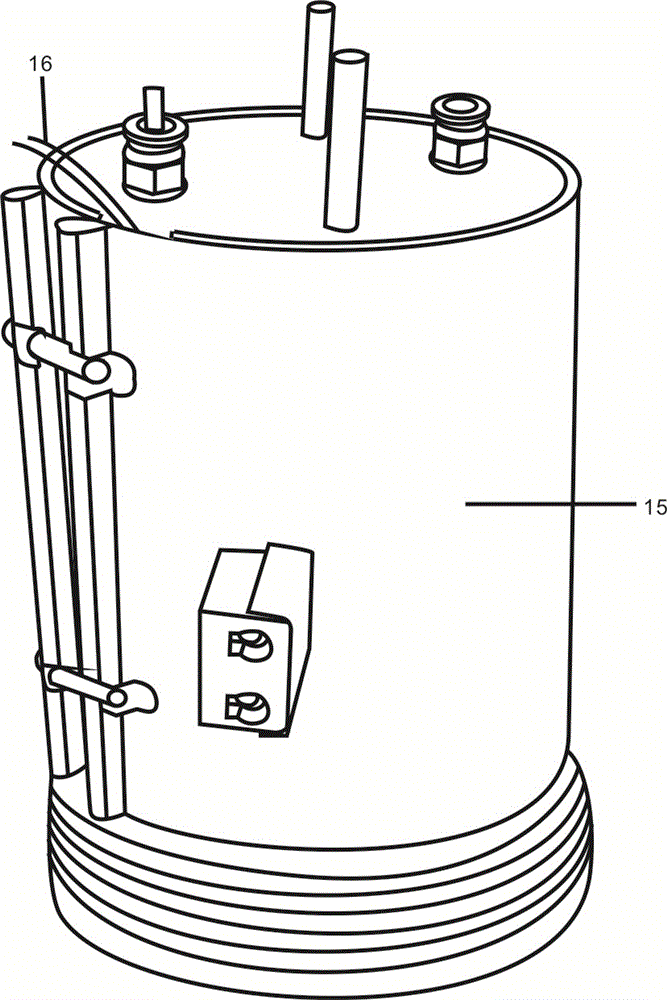

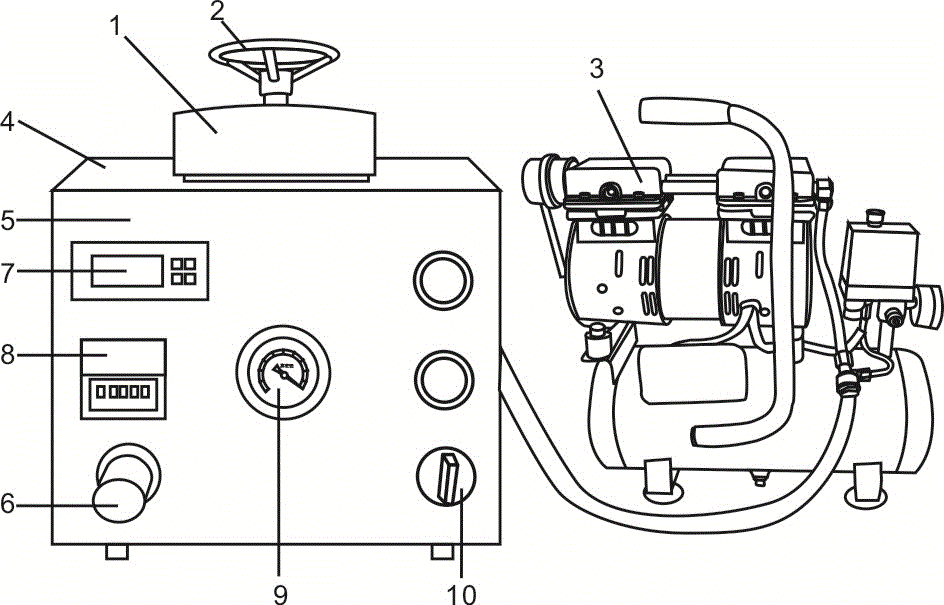

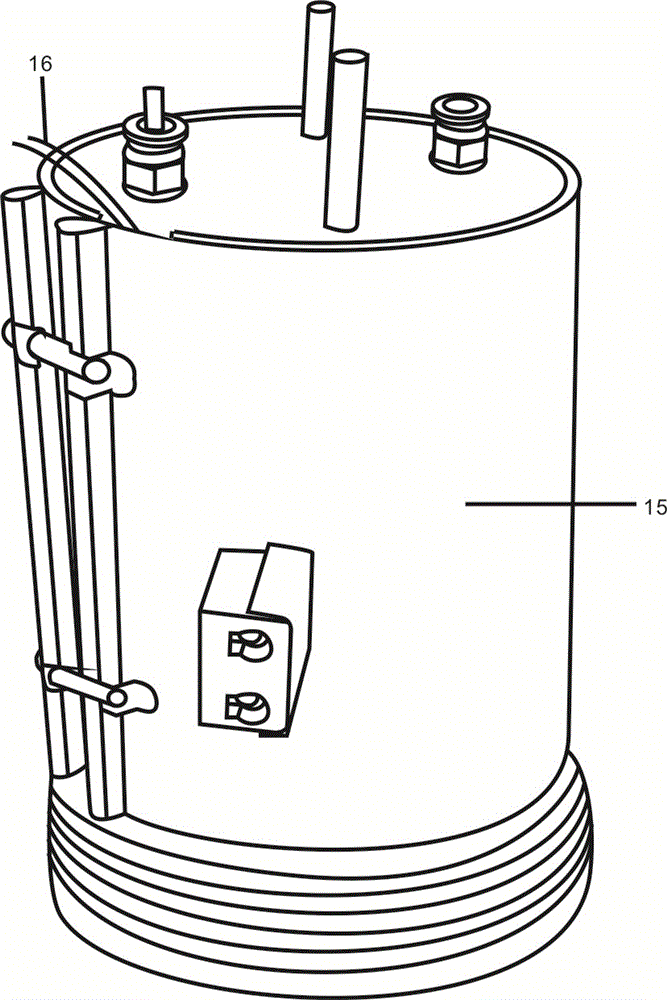

Safety pressurizing defoamer for mobile phone

InactiveCN104354441AEasy to operateEasy to popularize and useLamination ancillary operationsLaminationElectricityThermocouple

The invention discloses a safety pressurizing defoamer for a mobile phone. The safety pressurizing defoamer comprises a tank body, a tank cover, an electricity box, an air compressor, an annular heating ring, a thermocouple, an air inlet valve and an exhaust valve, wherein a control panel is arranged on the electricity box, and is provided with an button switch, a temperature controller, a time relay, a pressure regulating valve and a gas-pressure meter; a thread is arranged at the periphery of the top of the tank body; a groove is formed in the plane at the top of the tank body, and is provided with an O-shaped sealing ring; the tank body is vertically positioned in the electricity box; the part, below the thread, of the tank body is positioned in the electricity box, and the part, above the thread, of the tank body is positioned outside the electricity box; the tank cover is an integrated cap-shaped nut cover; the inner side of the tank cover is provided with a thread matched with the thread at the periphery of the top of the tank body; a hand wheel is arranged on the tank cover. The safety pressurizing defoamer for the mobile phone is safe, is simple to operate, and is easy to generally popularize and use.

Owner:GUANGDONG JINNUO COMM EQUIP

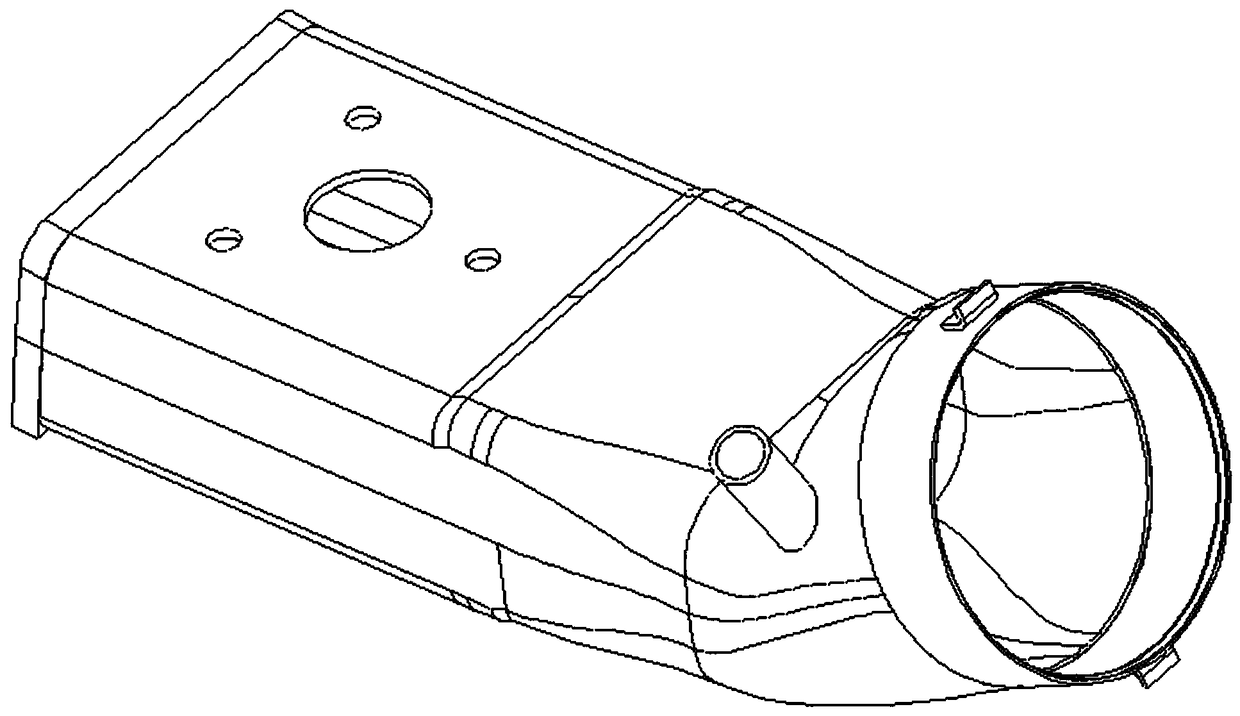

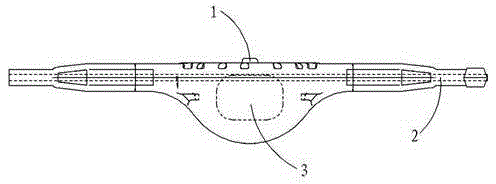

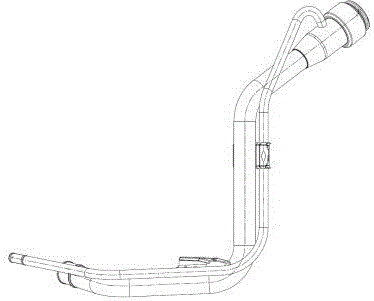

Water swelling forming technology of silencer of vehicle

ActiveCN109093330AImprove surface appearance qualityIncrease productivityPulp and paper industrySaponification

The invention discloses a water swelling forming technology of a silencer of a vehicle. The water swelling forming technology is characterized by comprising the following steps that a stainless steelpipe is cut off and burrs are removed; the stainless steel pipe is subjected to pipe bending based on appearance of a product; a bent pipe the subjected to solid melting process, and two ends of the bent pipe are formed by plugs to maintain the shape of the outer circle of the two ends; a cold pressing mold is adopted to one-time flatten the middle portion by a hydraulic machine, wherein the pressure applied by the hydraulic machine is greater than 315 tons; the product is subjected to solid melting process again; a blank material is positioned into a water swelling mold, and a water swellingmachine is used for pressing the mold; two pressurization cylinders push punches to extrude the pipe at two ends of the mold; saponification solution at 20MPa pressure is injected into inner holes ofthe punches; and after water swelling forming, a workpiece is cut off from the middle portion to form two parts. Parameters of water swelling forming are that pressure applied by the water swelling machine is 315 tons, pressure intensity is 20MPa, the output water pressure of the pressurization cylinders is greater than 160MPa, and the output pressure of left and right cylinders is greater than 20MPa.

Owner:广东思豪内高压科技有限公司

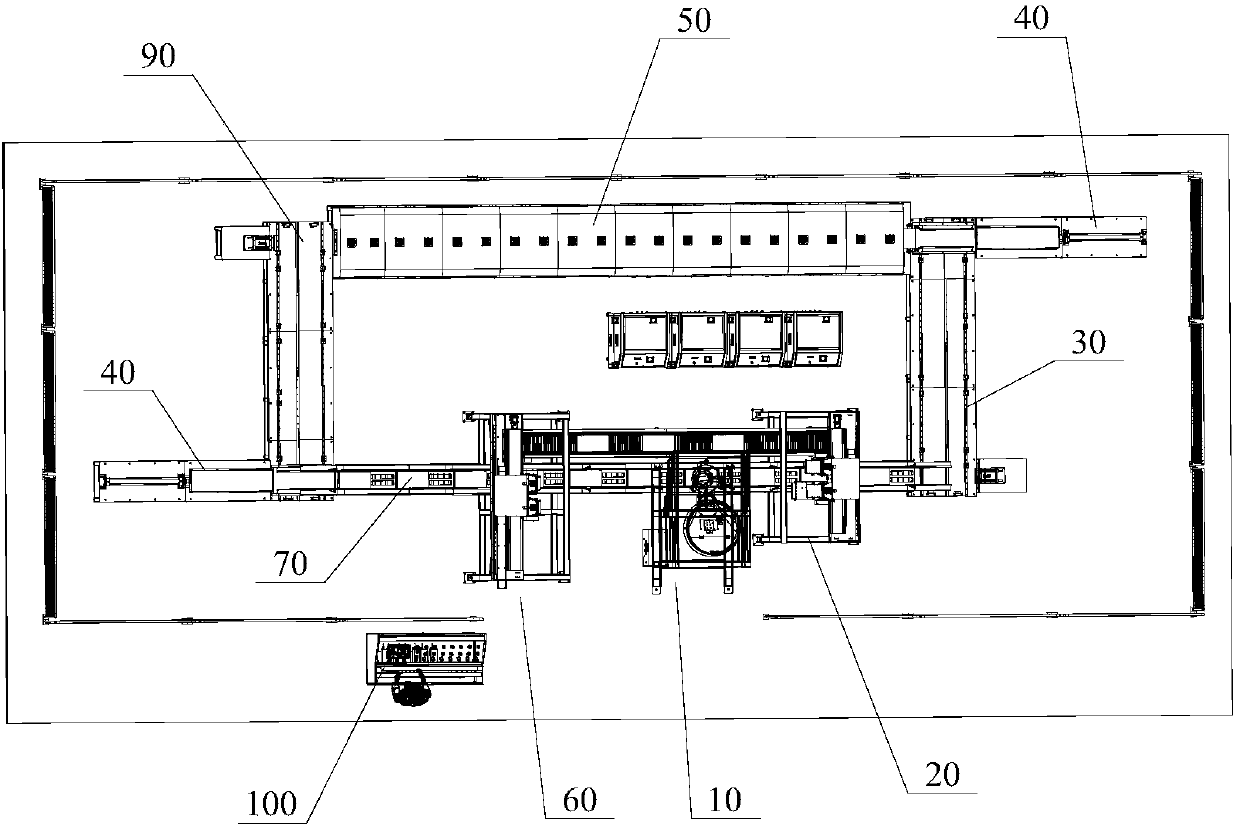

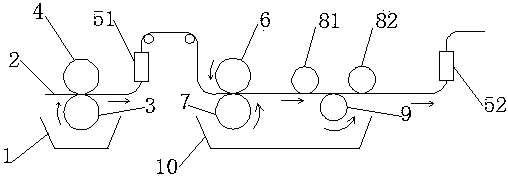

Full-automatic production line system for gold ingots and silver ingots

PendingCN107931548AThe surface of the product is smoothNo polishing requiredIngot casting plantsCelsius DegreeEngineering

The invention discloses a full-automatic production line system for gold ingots and silver ingots. The system comprises a weighing and unloading mechanism, a poking and cover closing mechanism, a first conveying car mechanism, a smelting furnace main body, a second conveying car mechanism and a cover opening and material taking mechanism in a conveying direction of a production line, which are insignal connection with a control system. The full-automatic production line system for the gold ingots and the silver ingots has the following advantages: an oriented solidification technology is adopted, so that product surfaces are smooth without needing polishing; through once molding under inert gas shielding, gold ingot and silver ingot products have no phenomenon, such as sand holes, air holes and uneven surfaces; sealed inert gas is adopted to protect smelting, so that the whole molding process is performed in sealing and protecting states without smoke emission; a smelting furnace is used for sealed machining; when internal temperature reaches 1450 DEG C, the external surface temperature is kept about 35 DEG C, so that no heat radiation is generated; and the whole process is operated through mechanical automation, so that the labor intensity of staff is low.

Owner:SHENZHEN JINDINGFENG PRECIOUS METALS EQUIP SCI & TECH CO LTD

Filter disc for X-ray and soft X-ray wave bands and preparation method thereof

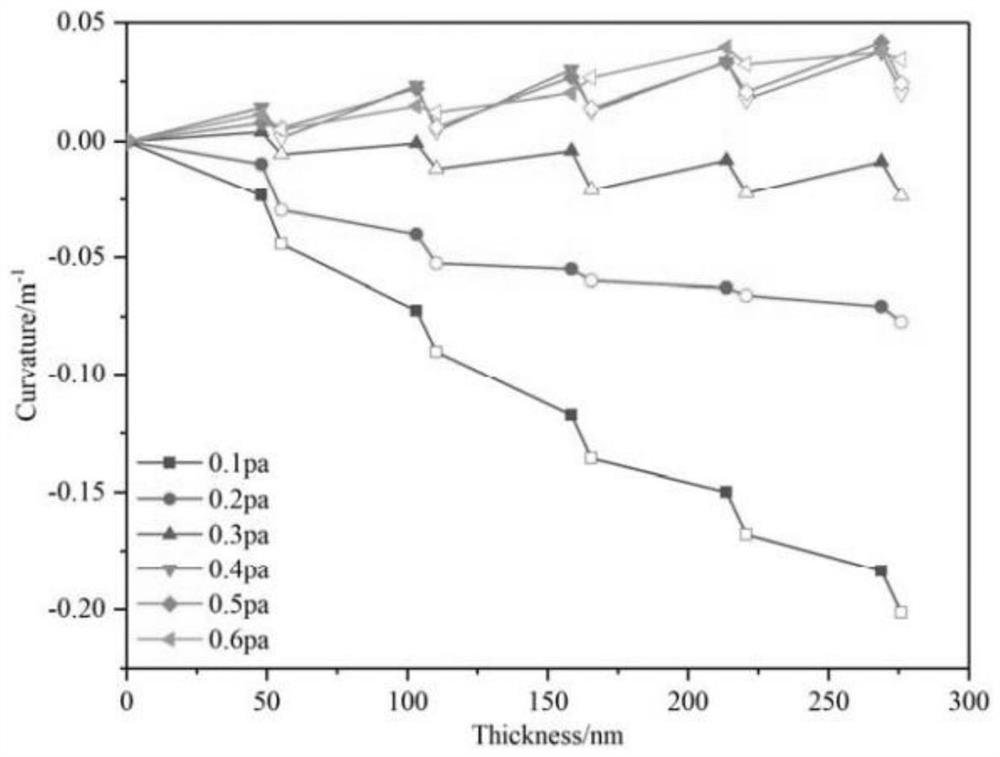

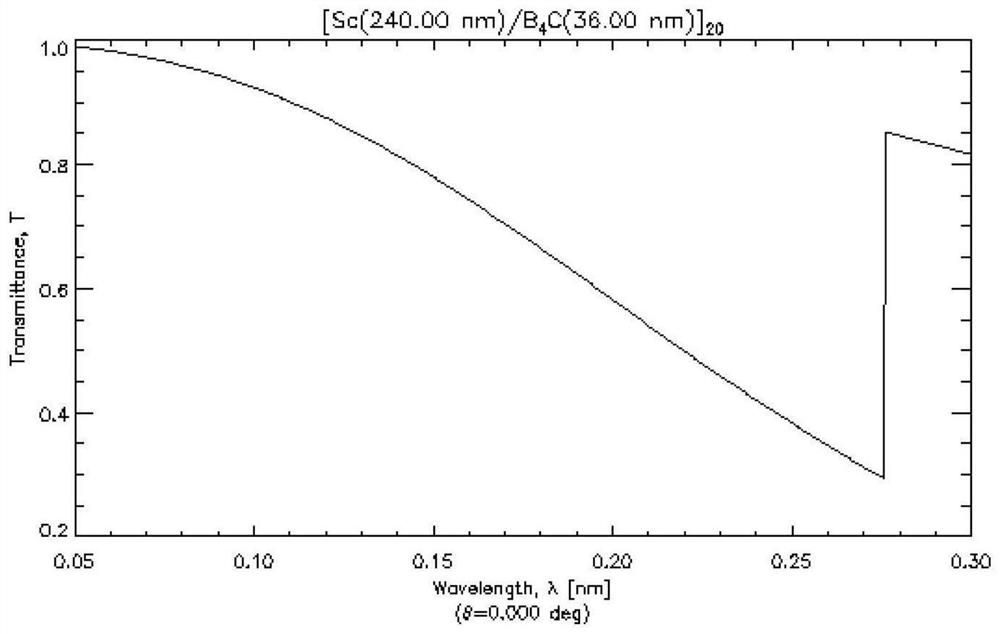

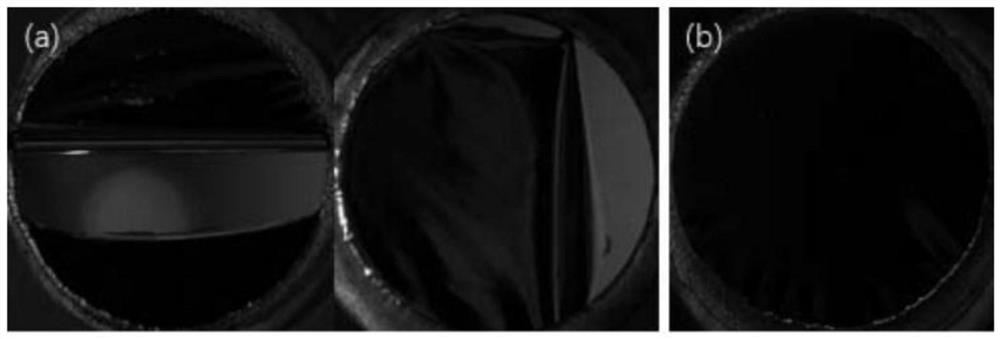

ActiveCN112820439AImprove qualityNo trachomaRadiation/particle handlingVacuum evaporation coatingTransmittancePolyimide membrane

The invention provides a filter disc for X-ray and soft X-ray energy bands and a preparation method of the filter disc, and belongs to the technical field of optical elements. The transmissivity of the filter disc containing an Sc layer is obviously compared before and after the K absorption edge is 0.276 nm (E=4500 eV) and the L absorption edge is 2.48 nm (E=500 eV). Due to the fact that the absorption edge of B is 190 eV, the filter disc provided by the invention can effectively restrain higher harmonics within the range of 0.276 nm to 0.31 nm (4000eV to 4500 eV) and the range of 2.48 nm to 6.53 nm (190 eV to 500 eV). According to the preparation method of the filter disc provided by the invention, a silicon wafer is etched firstly and then film coating is conducted, so that the obtained filter disc is high in quality and free of a sand hole phenomenon. The data of the embodiment shows that sand holes cannot be observed in the Sc / B4C filter disc or the self-supporting Sc / B4C filter disc (containing a polyimide film) prepared by the invention.

Owner:苏州闻道电子科技有限公司

Pipe fitting water swelling forming process for automobile engine

PendingCN110538916AImprove surface appearance qualityIncrease productivityPipe fittingForming processes

A pipe fitting water swelling forming process for an automobile engine includes the following steps of S1, pipe making, pipe cutting and deburring; S2, water swelling; S3, pipe cutting; S4, diameter determining; S5, cleaning; and S6, inspection. According to the process, a material is used for making a pipe, the pipe diameter matched with a water swelling mold is selected, heat treatment is performed after pipe making, then cutting is performed, and deburring is performed; then the pipe diameter is performed on the water swelling mold to abut against the two ends through a water shaft and a plugging part; the water shaft is provided with a water inlet, and jetting can be conveniently performed; the water shaft and the plugging part are correspondingly located on an upper mold cavity and alower mold cavity of the water swelling mold; the upper mold cavity and the lower mold cavity are each provided with an insert groove; and in the water swelling mold process step, the upper mold cavity, a middle mold cavity and the lower mold cavity can be adjusted according to the pipe diameter size.

Owner:CHANGCHUN JINJIANG AUTO PARTS

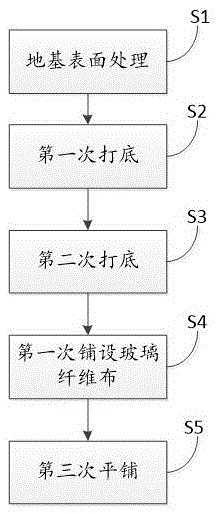

Foundation seamless corrosion-resistant waterproof construction process

The invention discloses a foundation seamless corrosion-resistant waterproof construction process. The process comprises the following steps that foundation surface treatment is conducted, specifically, earthworks of an original site of a foundation are treated and compacted, and the effect that the surface of the foundation is made to be flat to form a to-be-treated base surface is ensured; and first bottoming, second bottoming, first laying of glass fiber cloth and third tiling are conducted. By means of the foundation seamless corrosion-resistant waterproof construction process provided by the invention, used materials are high in adhesive force, and a corrosion-resistant waterproof face formed through construction has the advantages of being seamless, free of sand holes, leakage and falling, long in service life, high in anti-cracking performance, flexible in construction and the like. A compact armour layer which is resistant to acid, alkali, corrosion and cracking can be formed on the construction surface after construction is completed. The technical difficulties that previous foundation corrosion-resistant waterproof materials are poor in anti-cracking performance and not easy to construct are overcome; the effects that the foundation surface is seamless and free of sand holes and falling are really achieved; water resistance and leakage resistance of the foundation are completely achieved, and the gap in the field in China is filled.

Owner:王效禹

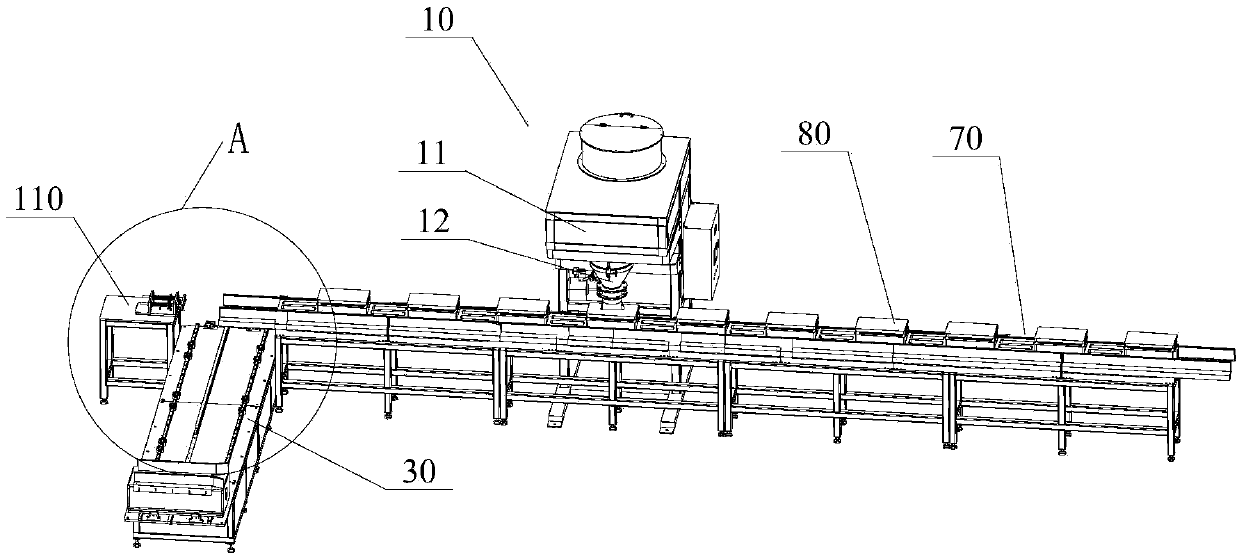

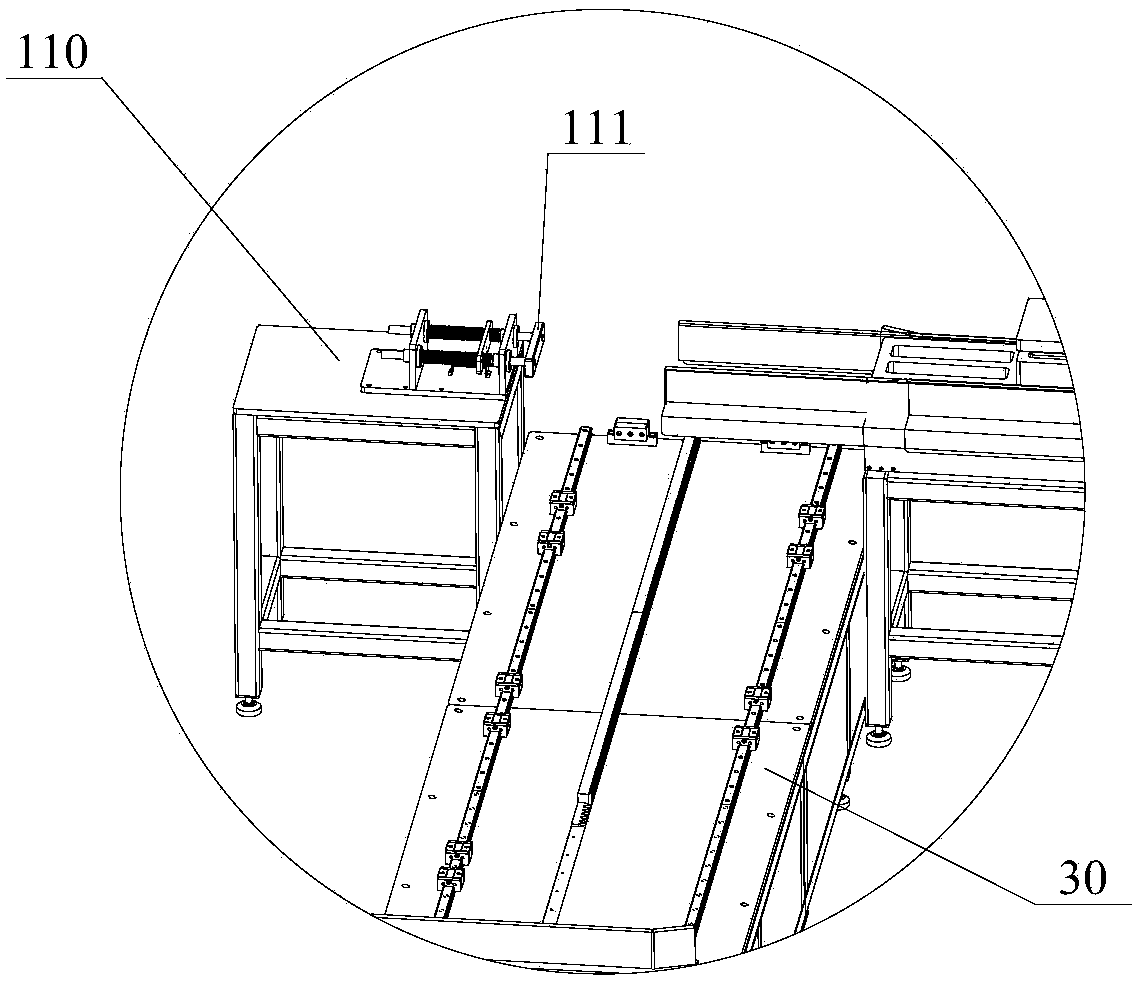

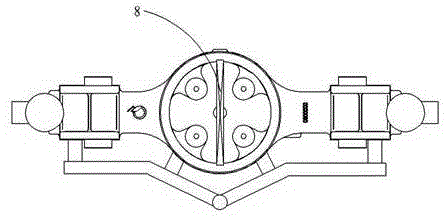

Elbow pipe integral forming production process and production device thereof

PendingCN114346047AUniform transmission of bulging forceReduce energy consumptionMolding machineEngineering

The invention discloses an elbow pipe integral forming production process and a production device thereof, the production process comprises the following steps of pipe blank preparation, pipe blank fixing, centering sealing, low-pressure water replenishing, pressurization water expansion, pressure relief pipe taking and elbow segmentation, and the production device comprises an elbow pipe water expansion forming mechanism; a water expansion mold in the elbow water expansion forming mechanism comprises an upper mold and a lower mold, the upper mold is provided with an upper half forming cavity, the lower mold is provided with a lower half forming cavity, and the lower half forming cavity and the upper half forming cavity are matched to form an elbow forming cavity. Side pressure cylinders are arranged at the two ends of the water expansion mold respectively, an expansion punch communicated with the water pressure injection cylinder is arranged at the telescopic end of the side pressure cylinder on one side, and a sealing plug assembly is arranged at the telescopic end of the side pressure cylinder on the other side. A large number of elbows can be manufactured through one-time water expansion, energy waste is reduced, and production efficiency is improved.

Owner:江苏博巴电器有限公司

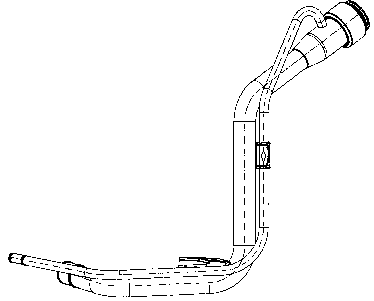

A welding method for fuel oil pipe

InactiveCN106077910BGuarantee structureImprove reliabilityArc welding apparatusSpin weldingPower flow

The invention belongs to the technical field of automobile part processing and particularly relates to a welding method for an oil filling pipe. The welding method comprises the steps that a filling pipe body, an exhaust pipe body, a spiral sleeve and a bracket are clamped into a welding mold at a time and pressed firmly through a mechanical hand, and all the parts are subjected to spot welding and fixing through an argon arc welding machine and copper alloy welding rods, taken out from the mold and then subjected to assembly welding; after welding is completed, gas tightness detection is conducted, then comprehensive test instrument detection is conducted according to the drawing size, and deformation adjustment needs to be conducted if the oil filling pipe is unqualified; surface anti-corrosion treatment is conducted; and high-temperature curing is conducted. According to the welding method for the oil filling pipe, argon arc welding spin welding and the copper welding rods are adopted, thus, the reliability is good, aging is not prone to happening, the structure of an original corrosion-resistant layer is ensured, and the service life is long; low-temperature welding is conducted, the effect that welding and fixing are stable is achieved, and meanwhile, a galvanized layer is not destroyed; and the optimum current and the optimum rotation speed are set, so that the anti-corrosion performance of the welded oil filling pipe is high, and no sand hole occurs.

Owner:张利

A kind of anti-corrosion and waterproof material and its preparation and use method

InactiveCN105419643BHigh strengthStrong adhesionProtective foundationAnti-corrosive paintsAdhesion forceOrganic solvent

Owner:王效禹

A flip casting method for 30f loader axle housing

Owner:LONGYAN SHENGWUQI AXLE

Welding method for oil filling pipe

InactiveCN106077910AGuarantee structureImprove reliabilityArc welding apparatusPower flowSpin welding

The invention belongs to the technical field of automobile part processing and particularly relates to a welding method for an oil filling pipe. The welding method comprises the steps that a filling pipe body, an exhaust pipe body, a spiral sleeve and a bracket are clamped into a welding mold at a time and pressed firmly through a mechanical hand, and all the parts are subjected to spot welding and fixing through an argon arc welding machine and copper alloy welding rods, taken out from the mold and then subjected to assembly welding; after welding is completed, gas tightness detection is conducted, then comprehensive test instrument detection is conducted according to the drawing size, and deformation adjustment needs to be conducted if the oil filling pipe is unqualified; surface anti-corrosion treatment is conducted; and high-temperature curing is conducted. According to the welding method for the oil filling pipe, argon arc welding spin welding and the copper welding rods are adopted, thus, the reliability is good, aging is not prone to happening, the structure of an original corrosion-resistant layer is ensured, and the service life is long; low-temperature welding is conducted, the effect that welding and fixing are stable is achieved, and meanwhile, a galvanized layer is not destroyed; and the optimum current and the optimum rotation speed are set, so that the anti-corrosion performance of the welded oil filling pipe is high, and no sand hole occurs.

Owner:张利

A kind of ultra-thin black light-shielding film and processing method thereof

ActiveCN107227107BThe overall thickness is thinReduce weightPolyurea/polyurethane coatingsFlat articlesWire rodSolvent

The invention relates to an ultrathin black light avoiding thin film and a processing method thereof. The paint is used for coating, and is prepared from the following materials: 15 to 20 weight percent of TPU resin, 0.1 to 0.2 weight percent of TDI, 0.2 to 0.4 weight percent of BYK-163 dispersing agents, 0.1 to 0.3 weight percent of TEGO-Glide 410 flatting agents, 3 to 5 weight percent of carbon black, 10 to 15 weight percent of pottery clay and the balance of solvents, wherein the solvent is formed by mixing butanone and ethyl acetate according to a volume ratio of 1:1. The obtained black light avoiding thin film disclosed by the invention has the advantages that the thickness is thin (8 to 13.5mu m); the weight is light (10 to 15g / m<2>); the processing is convenient; the light transmission rate is smaller than 0.01 percent. The coating disclosed by the invention adopts a gravure and wire rod sharing mode; the coating mode has the characteristics that the two kinds of modes can mutually make up shortcomings, so that a coating is fine, smooth and compact, and has no meshes or sand holes.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

Atomic ash

The present invention discloses an atomic putty. Its solidifying agent is formed from cyclohexanone peroxide, dibutyl phthalate and gas-phase white carbon black. It its main preparation, its all ingredients and their contents (by weight portion) are: unsaturated resin 100, styrene 0-17, talcum powder 130-195, Orr white and / or titanium pigment 0-5, active silicon dioxide 2-8, cobalt isocaprylate 1.5-3.5, ultramarine 0-1, tert-butyl pyrocatechol 0.01-0.5 and N.N-dimethyl aniline 0.125-0.3. It possesses the advantages of quick drying speed, strong adhesive force, good sanding property, good thixotropy, good weatherability, good stability and long storage time, and can be extensively used in the fields of automobile making and repairing industry, ship, locomotive, high-grade furniture and domestic electric appliances.

Owner:陈希元

Method for processing shell of industrial plug socket

InactiveCN101577394BLow priceLow costContact member cases/bases manufactureMachining processUltimate tensile strength

The invention provides a method for processing a shell of an industrial plug socket, which aims to solve the following problems that: the shell is manufactured by a die-casting process, and the marketcannot supply special-model anti-explosion electric connectors which have few demands but are necessary; the die-casting process generates air bubbles and sand holes so that the strength and the toughness of the shell are greatly reduced; and the shell produced by the die-casting process contains impurities, the surface almost cannot be subjected to oxidation treatment, the shell is easy to be eroded, and the explosion-proof performance is reduced. The key point is that the method adopts a machining process to process aluminum alloy pipes into shells. The method has the following advantages:standard sectional materials are selected, the raw materials are easy to get, the price is low, and the die cost is saved; the market supply is satisfied; the shell has no air bubbles and sand holes,and the strength and the toughness are greatly higher than that of shells produced by the die-casting process; and the aluminum alloy pipe materials contain no impurities, the surface is easy to perform the oxidation treatment, and the corrosion resistance is improved remarkably.

Owner:李贵阳

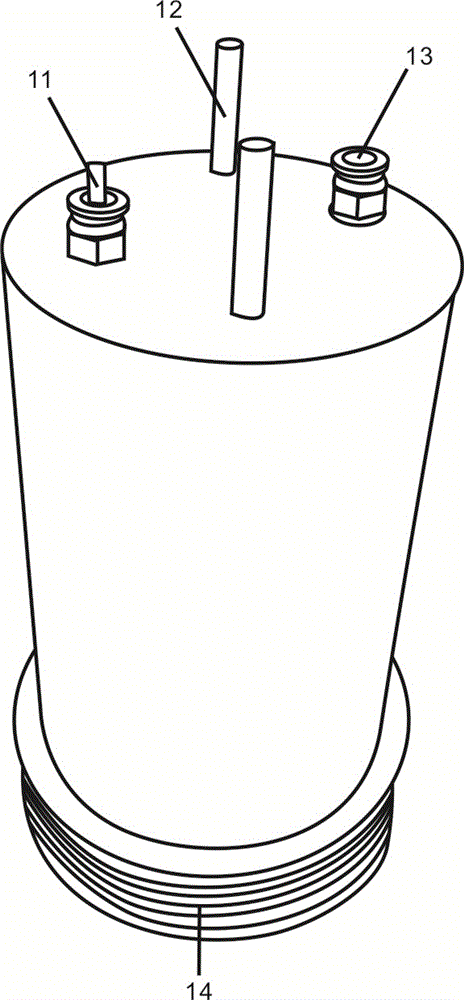

Mobile phone safety pressurized defoaming machine

InactiveCN104354441BNon-hazardousNo soldering requiredLamination ancillary operationsLaminationElectricityExhaust valve

The invention discloses a safety pressurizing defoamer for a mobile phone. The safety pressurizing defoamer comprises a tank body, a tank cover, an electricity box, an air compressor, an annular heating ring, a thermocouple, an air inlet valve and an exhaust valve, wherein a control panel is arranged on the electricity box, and is provided with an button switch, a temperature controller, a time relay, a pressure regulating valve and a gas-pressure meter; a thread is arranged at the periphery of the top of the tank body; a groove is formed in the plane at the top of the tank body, and is provided with an O-shaped sealing ring; the tank body is vertically positioned in the electricity box; the part, below the thread, of the tank body is positioned in the electricity box, and the part, above the thread, of the tank body is positioned outside the electricity box; the tank cover is an integrated cap-shaped nut cover; the inner side of the tank cover is provided with a thread matched with the thread at the periphery of the top of the tank body; a hand wheel is arranged on the tank cover. The safety pressurizing defoamer for the mobile phone is safe, is simple to operate, and is easy to generally popularize and use.

Owner:GUANGDONG JINNUO COMM EQUIP

Edge sealing mold with impermeable glue

Owner:凤城市东增铸造厂

A nitrate talc modified membrane for high temperature membrane gas meter

The invention relates to the technical field of materials, in particular to a nitric acid talc modified film for high-temperature membrane gas meters, including PET polyester fiber skeleton cloth, reinforced nitrile rubber, and double-sided PET polyester fiber skeleton cloth. Reinforced nitrile rubber is respectively coated, and the reinforced nitrile rubber includes nitrate talc and nitrile rubber body, and the weight percentage of nitrate talc in the reinforced nitrile rubber is 10-13%. Compared with the prior art, the present invention is made of PET polyester fiber skeleton cloth double-sided coated with reinforced nitrile rubber, which is characterized by high-temperature vulcanization, and the nitrile rubber reinforced with nitric acid talc can greatly improve its compatibility with polymers. Excellent compatibility, solves the difficulty of easy agglomeration and uneven dispersion in the polymer, so that the present invention has good mechanical properties, excellent thermal stability, and does not appear wrinkle when the service temperature is kept at 60-70 °C for a long time Pleated, delaminated, trachoma, lack of glue, cracking phenomenon, its tensile strength, elongation at break and flex performance are significantly improved.

Owner:ZENNER METERING TECH (SHANGHAI) LTD

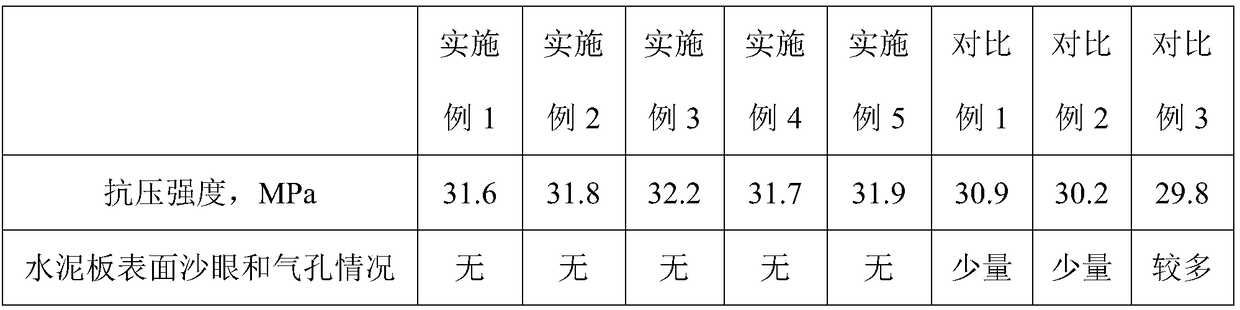

Sand hole and air vent resistant cement board

The invention discloses a sand hole and air vent resistant cement board. The sand hole and air vent resistant cement board is prepared from the following raw materials in parts by weight: 100-120 parts of cement, 20-30 parts of coal ash, 20-30 parts of glass beads, 10-15 parts of glass fibers, 5-10 parts of ultra-fine mineral powder, 8-12 parts of phenolic resin, 15-20 parts of aluminium silicate,0.2-0.5 part of sodium hydrogen sulfate, 10-15 parts of additive and 80-100 parts of water. The invention further discloses a preparation method of the sand hole and air vent resistant cement board.The prepared cement board is high in strength, smooth in surface, free of sand holes and air vents, better in durability, convenient to process subsequently and better in attractiveness under the action of cooperation of the various raw materials.

Owner:杨玲玲

Anti-corrosion waterproof material and preparing and using method thereof

InactiveCN105419643AHigh strengthStrong adhesionProtective foundationAnti-corrosive paintsAdhesion forceOrganic solvent

The invention discloses an anti-corrosion waterproof material and a preparing and using method of the anti-corrosion waterproof material. The anti-corrosion waterproof material is prepared from the following components in parts by weight: 50 to 70 parts of composite unsaturated resin, 5 to 10 parts of organic solvent, 3 to 6 parts of curing agent, 2 to 4 parts of catalyst and 25 to 40 parts of powder with anti-caking property in a mixing way. The anti-corrosion waterproof material disclosed by the invention has a stronger adhesion force, and an anti-corrosion waterproof surface which is formed through construction has the advantages of no joint, no air blister, no leakage, no falling, long service life, flexible construction and the like; a layer of tight armor can be formed on a construction surface after construction is completed, and the armor is anti-acid, anti-alkaline, anti-corrosion and anti-cracking; the technical difficulties of all anti-corrosion waterproof materials and construction in the past are broken through, the aims of no joint, no air blister and no falling are actually realized, the problem of waterproof leakage is thoroughly solved, and the blank in the domestic field is filled.

Owner:王效禹

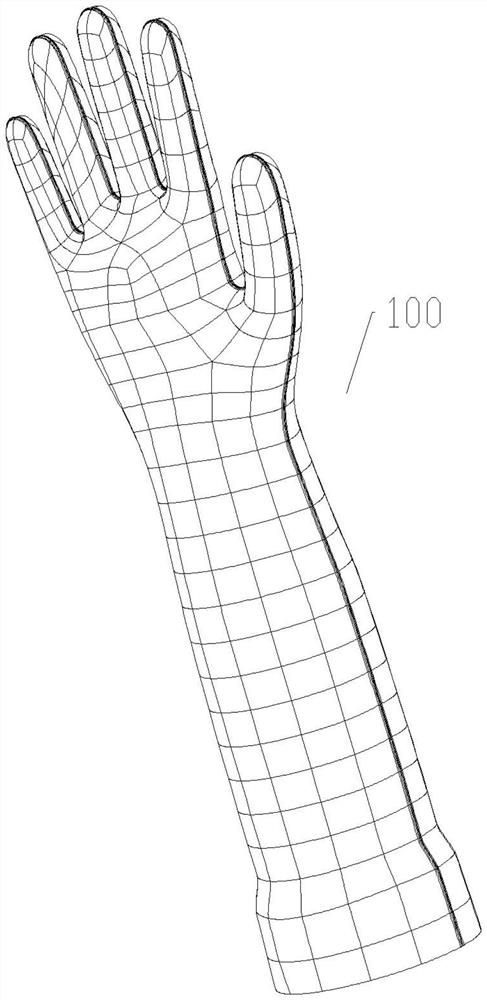

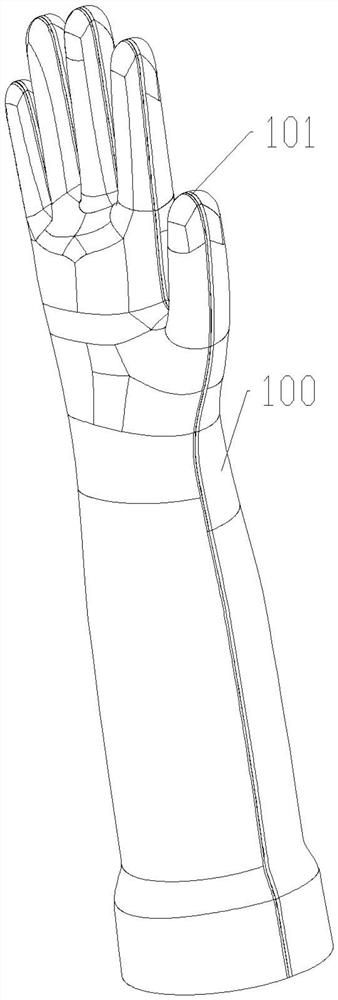

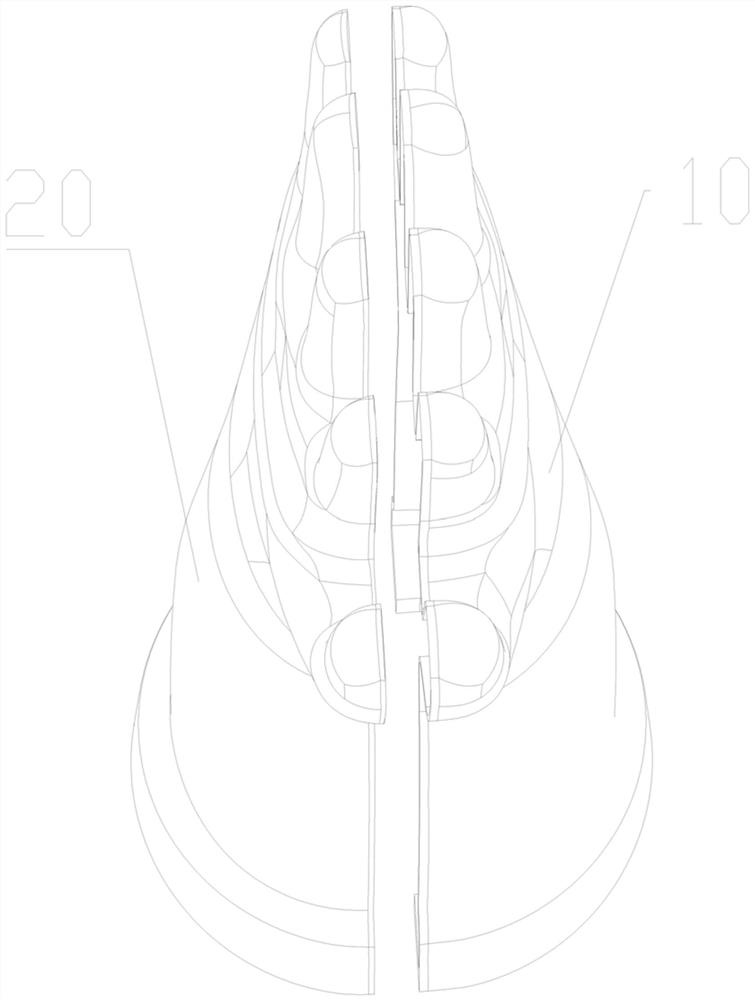

Metal hand model with spray painted surface and manufacturing method thereof

The invention discloses a metal hand model with a spray painted surface and a manufacturing method thereof. The metal hand model comprises a hand model main body, wherein the hand model main body is formed by mutually pressing and welding a hand model left half body and a hand model right half body and performing CNC machining; and a welding surface of the hand model left half body and the hand model right half body is not in a middle-dividing position. According to the metal hand model with the spray painted surface and the manufacturing method thereof, the welding surface of the hand model left half body and the hand model right half body is not in the middle-dividing position, and the hand model left half body and the hand model right half body are both provided with protruding edges; the hand model left half body and the hand model right half body are welded through the protruding edges to form the hand model main body; and the protruding edges are cut off through the CNC machining, so that the metal hand model is formed. A design concept of vacancy compensation is adopted, and the protruding edges are arranged to serve as welding compensation process lines, so that excess metal protruding out of the compensation process lines is melted to compensate sunken grooves in the surface during laser welding of the metal hand model. Therefore, the situation that the grooves are formed in a weld seam of the hand model main body after welding is avoided, and the surface of the hand model is ensured to be smooth and uniform without sand holes after the weld seam is machined through CNC.

Owner:李秋明

Ceramic composite cutter material and preparation method thereof

The invention discloses a ceramic composite cutter material and a preparation method thereof, wherein the ceramic composite cutter material mainly comprises 5-25 parts of ethyl methacrylate, 30-70 parts of titanium carbide, 5-27 parts of quartz, 5-24 parts of germanium oxide, 1-2 parts of palladium oxide, 1-2 parts of emery, 1-7 parts of silicon nitride, 0.1-0.5 part of boron nitride, 1-2 parts ofcarbon, 5-18 parts of nickel, 2-10 parts of cobalt, 4-8 parts of chromium, 1-3 parts of copper oxide, 0-1 part of cerium oxide, 0-1 part of glass fiber, and 0-1 part of neodymium oxide. According tothe present invention, powder preparing, billet material preparing, pre-molding, vacuum sintering, post-treatment and other steps are performed, and the process parameters are reasonably controlled soas to finally obtain the cutter composite material; and the operation is simple, and the product has advantages of chemical stability, low friction coefficient to steel, cutting melting resistance, cutting diffusion resistance and the like, and can cut refractory metal.

Owner:梁概泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com