Sand hole and air vent resistant cement board

A technology of cement board and pores, which is applied in the field of construction cement boards, can solve the problems of poor durability, unfavorable processing of trachoma and pores, trachoma depression, etc., and achieve better architectural aesthetics, convenient subsequent processing, and smooth surface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

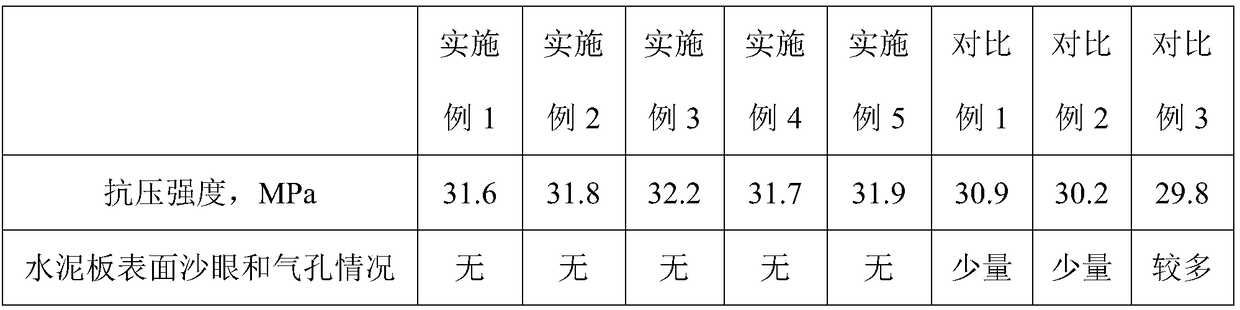

Examples

Embodiment 1

[0022] A cement board resistant to trachoma and pores, comprising the following raw materials in parts by weight: 100 parts of cement, 20 parts of fly ash, 20 parts of vitrified microspheres, 10 parts of glass fiber, 5 parts of ultrafine mineral powder, and 8 parts of phenolic resin 15 parts of aluminum silicate, 0.2 parts of sodium bisulfate, 10 parts of additives, and 80 parts of water.

[0023] Wherein, the additive is composed of coagulation regulator, water reducer, water retention agent, thickener and defoamer.

[0024] Wherein, the composition weight ratio of coagulation regulator, water reducer, water retaining agent, thickener and defoamer in the additive is 10:6:5:3.

[0025] In the present embodiment, the preparation method of the cement board resistant to trachoma and pores, the steps are as follows:

[0026] 1) Vitrified microspheres, glass fibers, phenolic resin and aluminum silicate are respectively pulverized and passed through a 150-mesh sieve to obtain vitri...

Embodiment 2

[0032] A cement board resistant to trachoma and pores, comprising the following raw materials in parts by weight: 105 parts of cement, 22 parts of fly ash, 23 parts of vitrified microspheres, 11 parts of glass fiber, 6 parts of ultrafine mineral powder, and 11 parts of phenolic resin 19 parts of aluminum silicate, 0.4 parts of sodium bisulfate, 14 parts of additives, and 95 parts of water.

[0033] Wherein, the additive is composed of coagulation regulator, water reducer, water retention agent, thickener and defoamer.

[0034] Wherein, the composition weight ratio of coagulation regulator, water reducer, water retaining agent, thickener and defoamer in the additive is 10:6:5:3.

[0035] In the present embodiment, the preparation method of the cement board resistant to trachoma and pores, the steps are as follows:

[0036] 1) Vitrified microspheres, glass fibers, phenolic resin and aluminum silicate are respectively pulverized and passed through a 180-mesh sieve to obtain vitr...

Embodiment 3

[0042] A cement board resistant to trachoma and pores, comprising the following raw materials in parts by weight: 110 parts of cement, 25 parts of fly ash, 25 parts of vitrified microspheres, 12 parts of glass fiber, 7 parts of ultrafine mineral powder, and 10 parts of phenolic resin 18 parts of aluminum silicate, 0.3 parts of sodium bisulfate, 13 parts of additives, and 90 parts of water.

[0043] Wherein, the additive is composed of coagulation regulator, water reducer, water retention agent, thickener and defoamer.

[0044] Wherein, the composition weight ratio of coagulation regulator, water reducer, water retaining agent, thickener and defoamer in the additive is 10:6:5:3.

[0045] In the present embodiment, the preparation method of the cement board resistant to trachoma and pores, the steps are as follows:

[0046] 1) Vitrified microspheres, glass fibers, phenolic resin and aluminum silicate are respectively pulverized and passed through a 180-mesh sieve to obtain vitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com