Foundation seamless corrosion-resistant waterproof construction process

A construction technique and seamless technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve problems such as poor weather resistance, personal and property injuries of residents, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

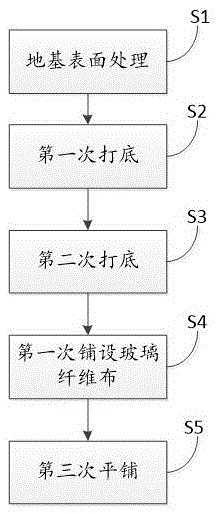

[0027] See figure 1 , Is a jointless anti-corrosion and waterproof construction technology for foundation provided by embodiments of the present invention, such as figure 1 As shown, the process includes the following steps:

[0028] S1. Surface treatment of the foundation: compaction of the original site earthwork of the foundation and ensure that its surface is flat to form the base to be treated;

[0029] In specific implementation, the soil on the surface of the foundation to be treated can be compacted with the help of tools, and the compacted surface should be as smooth as possible, so that the formed base surface to be treated can ensure that the material can be laid evenly when laying anti-corrosion and waterproof materials. , Which helps to ensure its durability.

[0030] S2. The first primer: Take 50 to 70 parts of composite unsaturated resin, 5 to 10 parts of organic solvent, 3 to 6 parts of curing agent, and 2 to 4 parts of catalyst to make a primer. The liquid is even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com