Metal hand model with spray painted surface and manufacturing method thereof

A manufacturing method and hand mold technology, applied in the direction of coating, etc., can solve the problems of trachoma, many internal defects, low product qualification rate, etc., and achieve the effect of uniform trachoma, no trachoma, and smooth surface of the hand mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

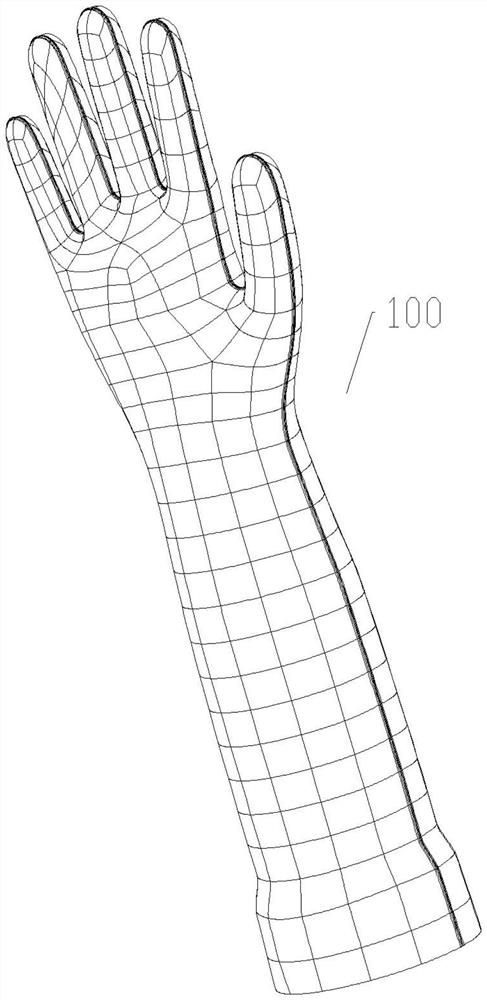

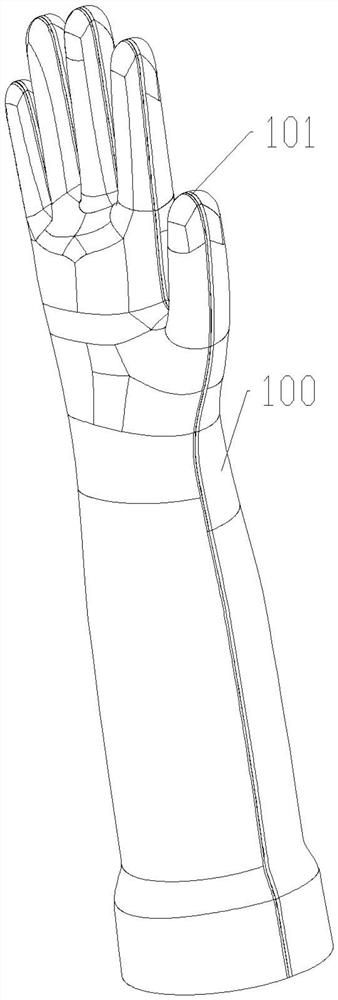

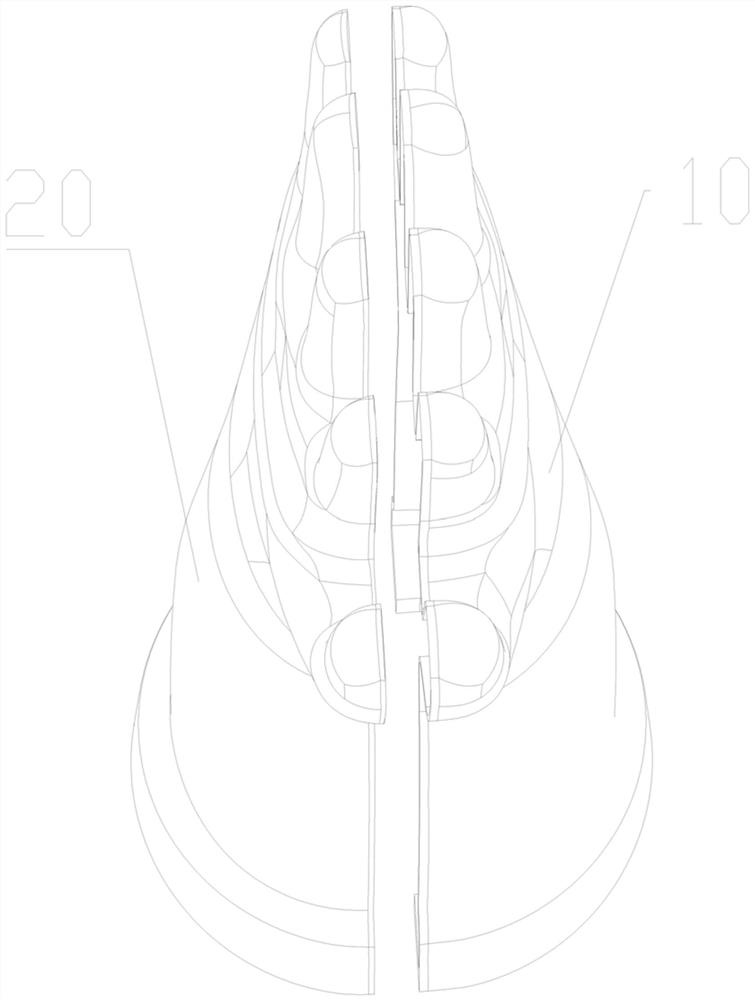

[0047] Such as Figure 1-9 As shown, the present invention provides an embodiment of a metal hand mold with spray paint on the surface, including a hand mold body 100, and the hand mold body 100 is formed by pressing the left half body 10 of the hand mold and the right half body 20 of the hand mold against each other, welding and CNC processing The hand mold left half body 10 and the hand mold right half body 20 are die-casted and welded into the hand mold main body 100; the surface of the hand mold main body 100 is provided with a ceramic paint layer, and the ceramic paint layer is processed on the hand mold main body 100 surface by electrostatic spraying . Specifically, the left half body 10 of the hand mold and the right half body 20 of the hand mold are molded by die casting. The welding surfaces of the left half body 10 of the hand mold and the right half body 20 of the hand mold are not in the middle position. The surface of the hand mold main body 100 is provided with...

Embodiment 2

[0060] The present invention also provides a method for making a metal hand mold with surface spray painting. The production process from die-casting hand mold processing to surface treatment includes: designing hand mold mold → making hand mold mold → hand mold die-casting forming → stamping to remove burrs → inspection → laser welding →Inspection→CNC processing→inspection→polishing and grinding→sand blasting→inspection→surface treatment (film+baking+spraying ceramic paint)→baking→inspection; the specific production process includes the following steps:

[0061] (1) Make hand molds, design, manufacture and develop metal hand molds, including the left half of the hand mold and the right half of the hand mold; specifically, design and develop independent metal hand molds through metal hand molds, including 10 molds for the left half of the hand mold and 2 molds for the right half of the hand mold 20 molds.

[0062] (2) making hand mold blanks, making metal hand mold blanks by d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com