Seamless, corrosion-resistant and waterproof construction process for wall

A construction technology, seamless technology, used in building maintenance, construction, coating and other directions, can solve problems such as poor weather resistance, loss of waterproof effect when separated from the base layer, and excessive external erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

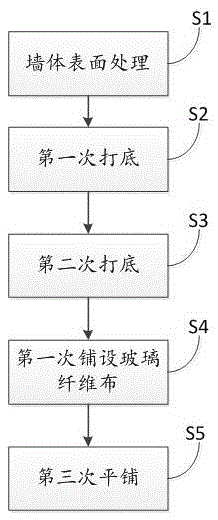

[0025] see figure 1 , is a schematic flow chart of a seamless wall anti-corrosion and waterproof construction process provided by an embodiment of the present invention, as shown in figure 1 As shown, the process includes the following steps:

[0026] S1. Wall surface treatment: fill and repair the cracks on the wall surface, and ensure that the wall surface is flat to form a base surface to be treated;

[0027] In practical applications, the surface of the wall to be treated for anti-corrosion and waterproof treatment is firstly filled and repaired. Cement mortar and other materials can be used to fill and repair the cracks existing in the wall. There is a consistent surface, which can make the surface of the base surface to be treated smooth, which is conducive to the consistency of laying anti-corrosion and waterproof materials on its upper part. Of course, in actual application, if there is peeling and peeling on the surface of the wall, it can be treated first to clean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com