Water-soluble photosensitive ink as well as preparation method and construction method thereof

A photosensitive ink and water-soluble technology, applied in the field of water-soluble photosensitive ink and its preparation, can solve the problems of short circuit, hidden danger of solvent or ink fire safety, easy to disperse and the like, achieve simple preparation steps, reduce sedimentation and layering phenomenon, Good castability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0057] A kind of aqueous photosensitive resin, its preparation comprises the steps:

[0058] Mix 10kg of water and 16kg of co-solvent evenly, then add 40kg of acrylic resin, mix and stir to dissolve, and use an alkali neutralizer to adjust the pH value to 8 to obtain an acrylic resin solution;

[0059] Add 0.1 kg of polymerization inhibitor, 3.9 kg of catalyst and 30 kg of glycidyl methacrylate to the acrylic resin solution in sequence, and react for 15 hours while keeping the temperature at 80° C. to obtain a water-sensitive photosensitive resin.

preparation example 2-3

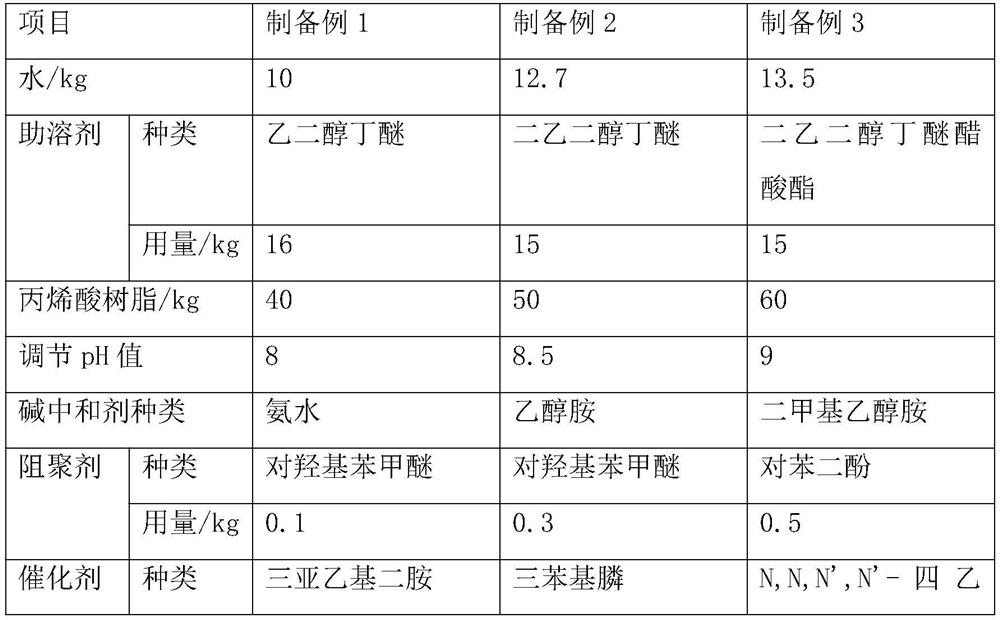

[0061] The difference between Preparation Example 2-3 and Preparation Example 1 lies in the differences in the amount, type and process parameters of raw materials, see Table 1 below for details.

[0062] The raw material of table 1 preparation example 1-3 and process condition comparison table

[0063]

[0064]

preparation example 4

[0066] The difference between this preparation example and the above-mentioned preparation example 2 is: first add glycidyl methacrylate to water and a cosolvent to disperse, add a polymerization inhibitor and a catalyst, and then add an acrylic resin. The specific steps are as follows:

[0067] Mix 15kg of water and 12.7kg of co-solvent evenly, then add 20kg of glycidyl methacrylate, mix and stir; then add 0.3kg of polymerization inhibitor, 2kg of catalyst and 50kg of acrylic resin in sequence, and keep the temperature at 85°C for 13 hours , to prepare water-sensitive photoresin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com