A welding method for fuel oil pipe

A welding method and technology for refueling pipes, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of easy aging, low service life, large heating area, etc., and achieve strong anti-corrosion performance, long service life, and reliability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

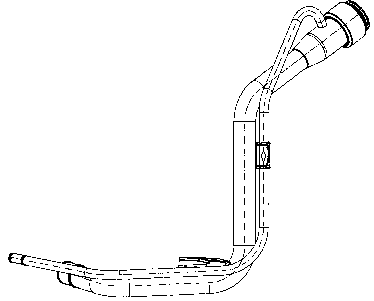

Image

Examples

Embodiment 1

[0020] A welding method for fueling pipes. The filling pipes, exhaust pipes, spiral sleeves, and brackets are clamped into the welding mold at one time and pressed firmly with mechanical hands. Argon arc welding machines and copper alloy welding rods (alloy copper welding rods are used The SCu6560 copper alloy welding rod produced by Beijing Yida Kuntai Technology Co., Ltd. is used to fix the parts by spot welding, take them out of the mold, and then perform assembly welding. When welding the filling pipe, exhaust pipe and bracket, it is argon arc welding. The current used is: 98A, and the welding spiral sleeve is argon arc welding rotary welding. The used current is: 110A; the linear speed is: 15-16mm / s, and the welding process is formed at one time. After the welding is completed, check the air tightness to check whether there are air holes. Use the air compressor to immerse the filling pipe in the water tank to see if there are bubbles. Set the pressure at 0.02MPa for 30s to...

Embodiment 2

[0022] A welding method for fueling pipes. The filling pipes, exhaust pipes, spiral sleeves, and brackets are clamped into the welding mold at one time and pressed firmly with mechanical hands. Argon arc welding machines and copper alloy welding rods (alloy copper welding rods are used The SCu6560 copper alloy welding rod produced by Beijing Yida Kuntai Technology Co., Ltd. is used to fix the parts by spot welding, take them out of the mold, and then perform assembly welding. When welding the filling pipe, exhaust pipe and bracket, it is argon arc welding. The current used is: 98A, and the welding spiral sleeve is argon arc welding rotary welding, the used current is: 110A; the linear speed is: 15mm / s, and the welding process is formed at one time. After the welding is completed, check the air tightness to check whether there are air holes. Use the air compressor to immerse the filling pipe in the water tank to see if there are bubbles. Set the pressure at 0.02MPa for 30s to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com