Fixing tool for fire hydrant connecting elbow welding

A technology for connecting elbows and fixing tools, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems that affect the appearance quality and use function of the fire hydrant system, can not be convenient and fast welding construction, welding interface deviation, etc., to achieve Good welding effect, no trachoma, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

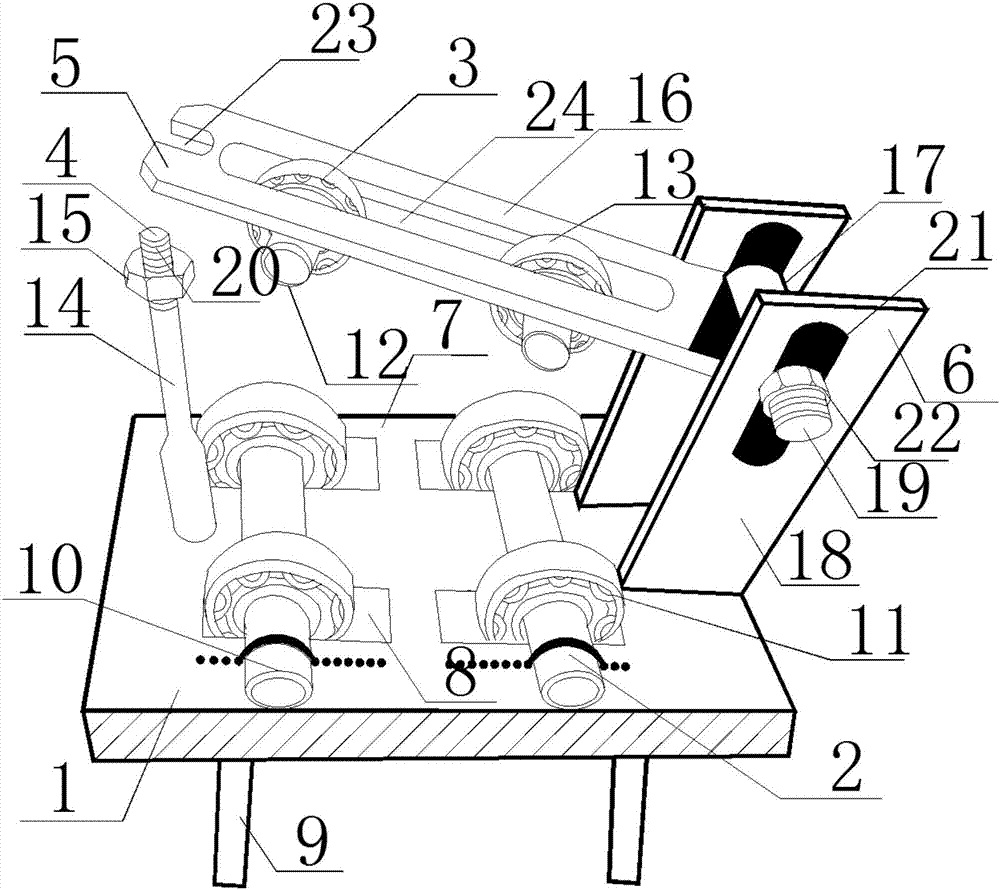

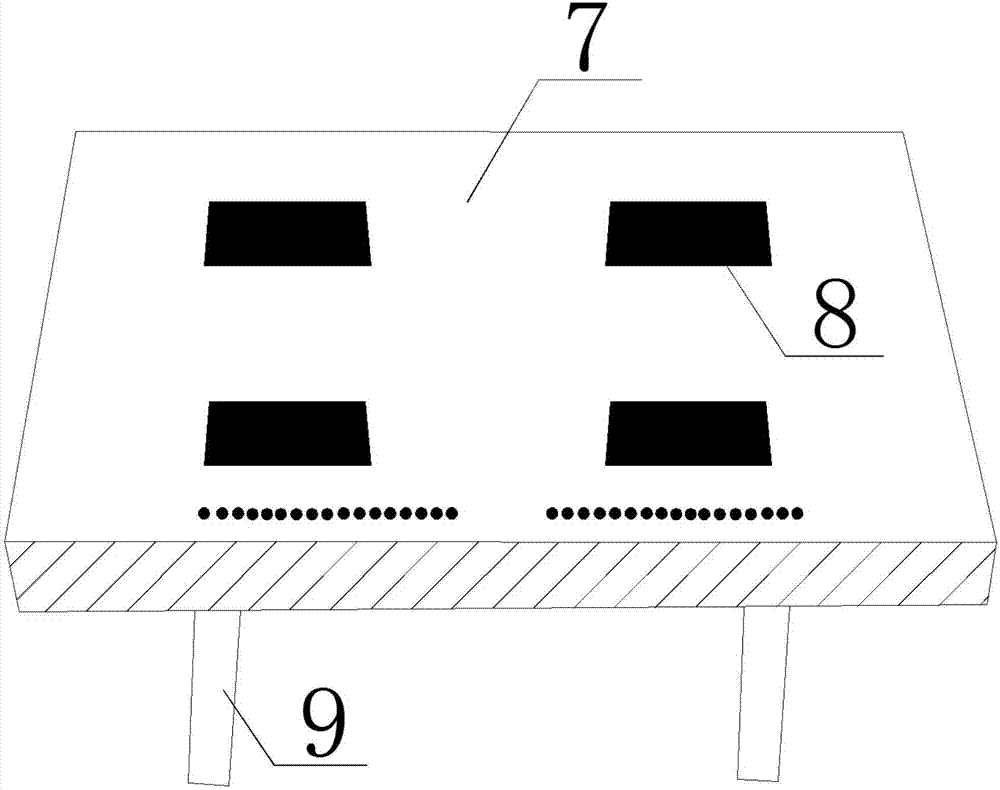

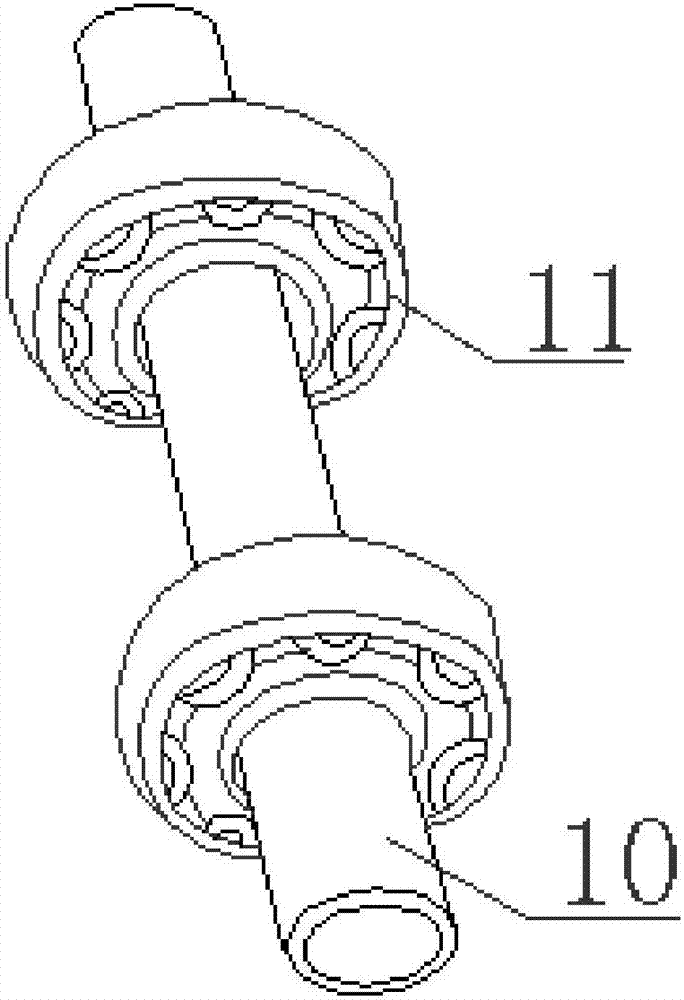

[0023] Such as figure 1 Shown is a fixing tool for fire hydrant connection elbow welding, including an operating table 1, a large transmission shaft mechanism 2, a small transmission shaft mechanism 3, a fixing device 4, a pressing plate mechanism 5 and an adjustable bolt device 6. The large transmission shaft mechanism 2 is installed in the middle of the console 1; the fixing device 4 and the adjustable bolt device 6 are respectively located on both sides of the large transmission shaft mechanism 2 and fixedly installed on the console 1; the pressing plate mechanism 5 is located on the Above the large transmission shaft mechanism 2 and one end of the pressing plate mechanism 5 is connected to the adjustable bolt device 6, and the other end of the pressing plate mechanism 5 acts on the fixing device 4; the position of the pressing plate mechanism 5 relative to the large transmission shaft mechanism 2 is determined by the adjustable bolt device 6 adjustment, fixed by the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com