Edge sealing mold with impermeable glue

A mold and edge banding technology, which is applied in the field of turbocharger mold design, can solve the problems of glue seeping into the mold cavity, low product qualification rate, and waste products, so as to improve work efficiency, ensure product quality, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Combined with the manual Figure 1-4 The present invention is further described in detail.

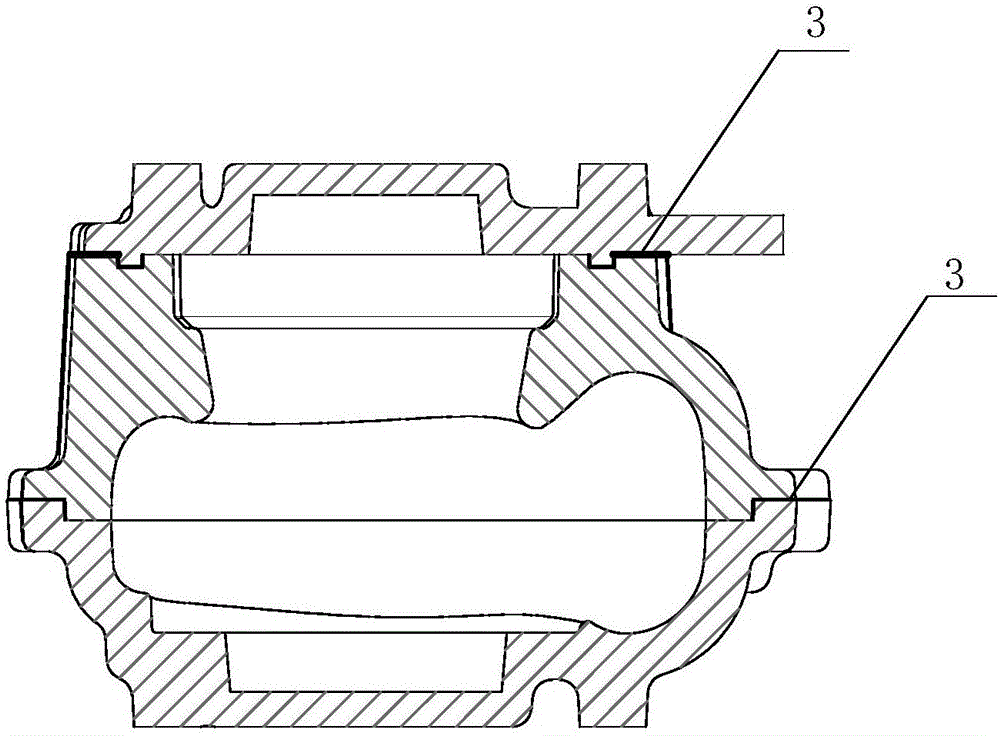

[0023] An edge-sealing mold with anti-glue seepage, said mold is formed by combining and bonding an upper mold, a middle mold and a lower mold;

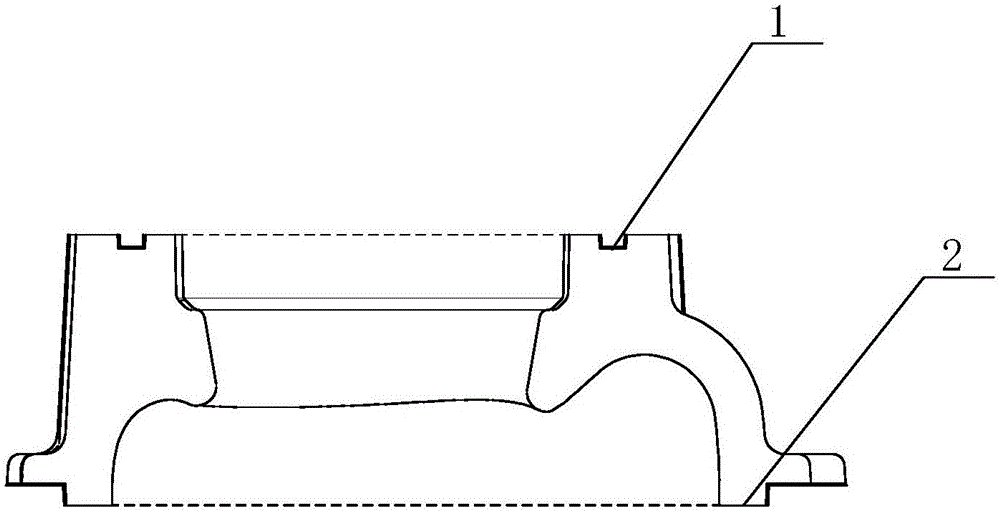

[0024] The upper mold is provided with a downward protrusion, and the upper part of the middle mold is provided with a groove 1 corresponding to the protrusion;

[0025] Apply glue 3 on the contact surface of the upper mold and the middle mold, and the glue will stop in the groove 1 after being squeezed to avoid flowing into the mold cavity;

[0026] The lower part of the middle mold is provided with a downward step 2, and the upper part of the lower mold is provided with a notch corresponding to the step;

[0027] Apply glue 3 on the contact surface of the middle mold and the lower mold, and stop the glue at the step after extrusion; avoid flowing into the mold cavity.

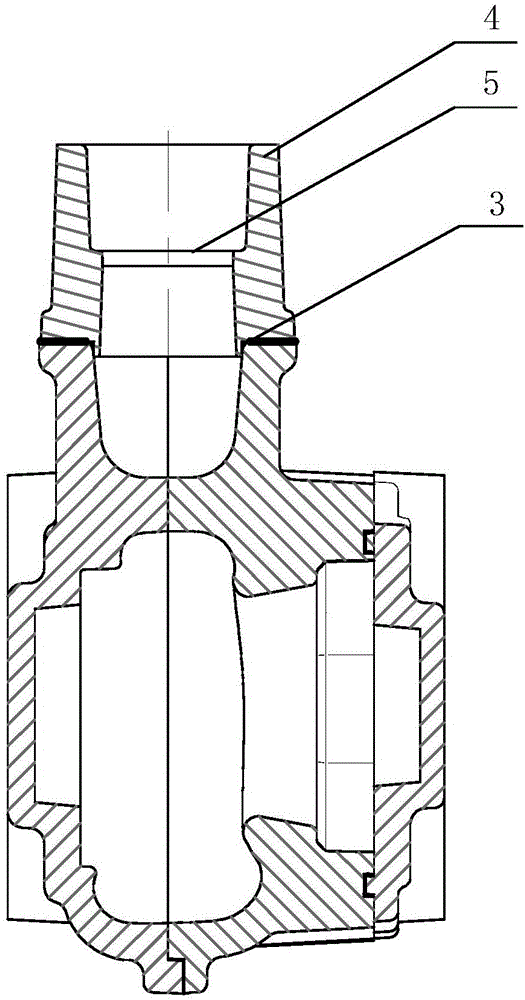

[0028] The mold is also provided with a sprue cup 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com