A kind of anti-corrosion and waterproof material and its preparation and use method

A waterproof material and hybrid technology, which is applied in anti-corrosion coatings, building insulation materials, building components, etc., can solve the problems of poor material hardness, loss of waterproof effect when separated from the base layer, and easy bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first embodiment of the present invention provides an anticorrosive and waterproof material, which is prepared by mixing the following components in parts by weight: 50 to 70 parts of composite unsaturated resin, 5 to 10 parts of organic solvent, 3 to 6 parts of curing agent, 2 to 4 parts of catalyst and 25 to 40 parts of powder with anti-caking properties; wherein, the composite unsaturated resin is a composite unsaturated resin prepared by adding nano-scale carbon fibers to the unsaturated resin, and the unsaturated resin is mixed with The weight ratio of the nano-sized carbon fiber is (6-15): (1-5), the nano-sized carbon fiber is used to increase the strength of the composite unsaturated resin after curing; the powder with anti-caking properties is The nano-level powder with anti-caking properties obtained after grinding treatment. In practical application, the material is prepared by mixing the following raw materials in parts by weight: 55 to 65 parts of composi...

Embodiment 2

[0031] The second embodiment of the present invention provides a method for preparing an anticorrosive and waterproof material, and the method includes:

[0032] Take 6 to 15 parts by weight of unsaturated resin and 1 to 5 parts by weight of carbon fiber, subject the carbon fiber to grinding treatment to obtain a milled nanoscale carbon fiber, and add the obtained nanoscale carbon fiber to the unsaturated resin The composite unsaturated resin is prepared by mixing and mixing uniformly; in practical applications, when preparing the composite unsaturated resin, 6 parts by weight of unsaturated resin and 1 part by weight of carbon fiber can be taken, and the carbon fiber is ground. , Obtain the milled nano-scale carbon fiber, add the obtained nano-scale carbon fiber into the unsaturated resin and stir uniformly to prepare a composite unsaturated resin; further it can be 8 parts by weight of unsaturated resin and 4 parts by weight Carbon fiber, the carbon fiber is ground to obtain a ...

Embodiment 3

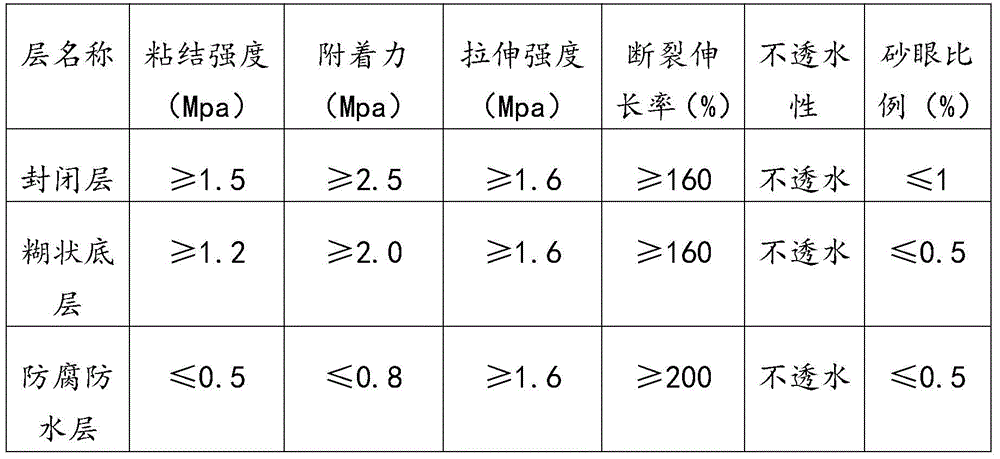

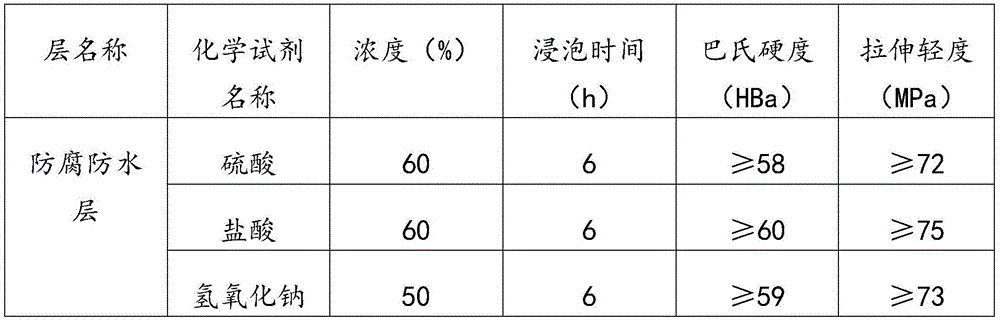

[0034] The third embodiment of the present invention provides a method for using an anticorrosive and waterproof material, and the method includes:

[0035] The first primer: Take 50 to 70 parts of composite unsaturated resin, 5 to 10 parts of organic solvent, 3 to 6 parts of curing agent, and 2 to 4 parts of catalyst to make a primer and mix the primer evenly. Lay it on the surface of the part to be treated with anticorrosion and waterproofing to form a sealing layer; in actual application, 50 parts of composite unsaturated resin, 5 parts of organic solvent, 3 parts of curing agent, and 2 parts of catalyst can be mixed to make a primer. It is also possible to take 60 parts of composite unsaturated resin, 8 parts of organic solvent, 4 parts of curing agent, and 3 parts of catalyst to mix evenly to prepare a primer. It is also possible to mix 70 parts of composite unsaturated resin, 10 parts of organic solvent, 6 parts of curing agent, and 4 parts of catalyst to make a primer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com