Turn-over type roof system

A roof system and flip-type technology, applied in the field of animal husbandry infrastructure construction, can solve problems such as the inability to effectively solve the problem of light in cowsheds, and achieve the effects of improving land use efficiency, reducing area, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

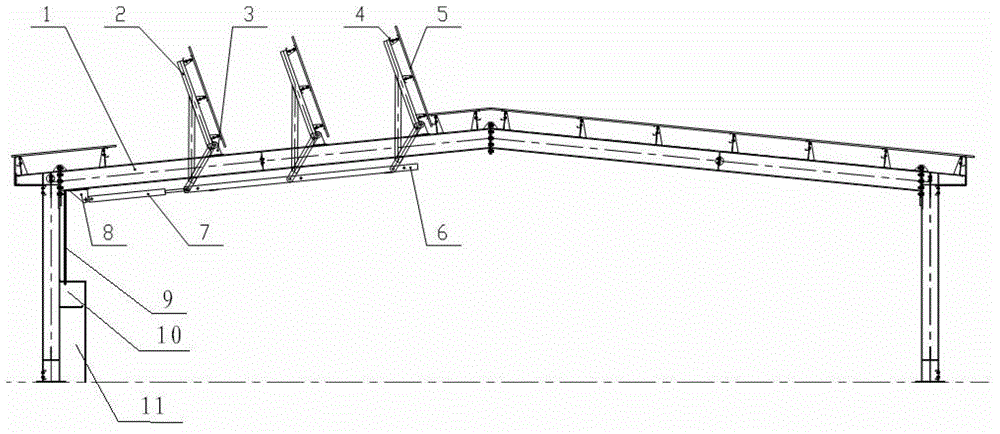

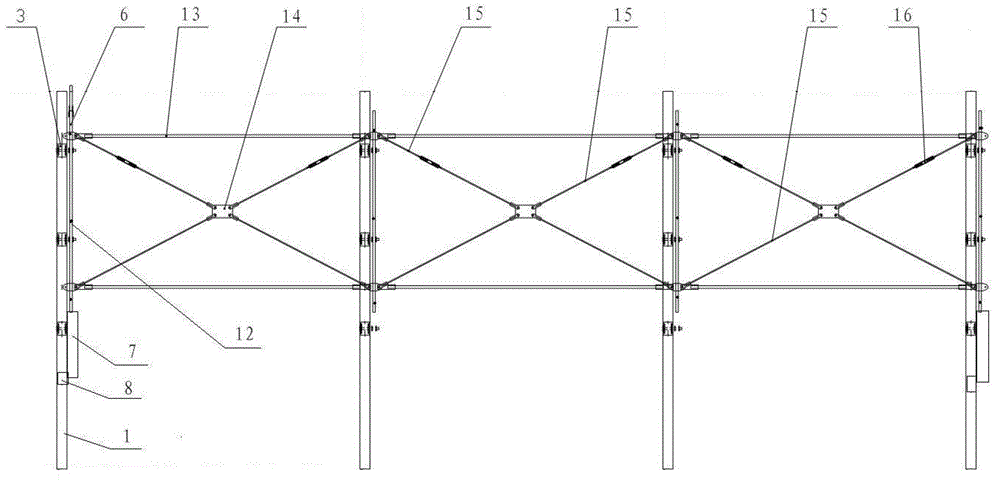

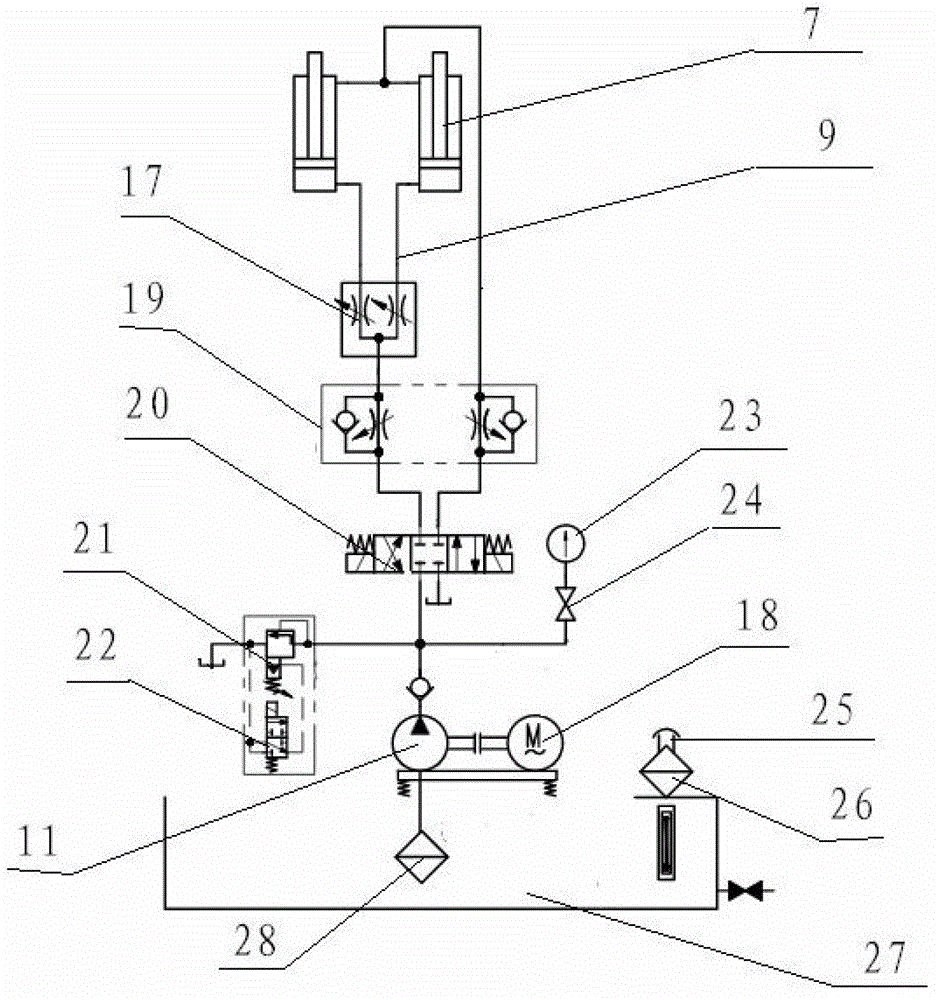

[0028] The flipped roof system of the present invention includes a roof part, a horizontal support part, a hydraulic part, and an electric control part. A flipped roof panel 5 is installed in the middle of one side of the roof. Generally, cowsheds are facing north and south, and only need to be installed on the sunny side. Just turn the roof over. If you want to expand the area of the house to obtain light, you can design the roof to have a longer side of the side of the side of the side of the side of the side of the side of the side of the side of the side of the side, while the side of the shade is shorter; On the long side of 2, the apex of the flip bracket 2 is hinged on the bracket fixing seat 3 through a pin shaft, and the bracket fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com