Prediction method of lithium-ion battery cut-off voltage based on ari algorithm

A lithium-ion battery and cut-off voltage technology, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problem of low prediction accuracy and achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

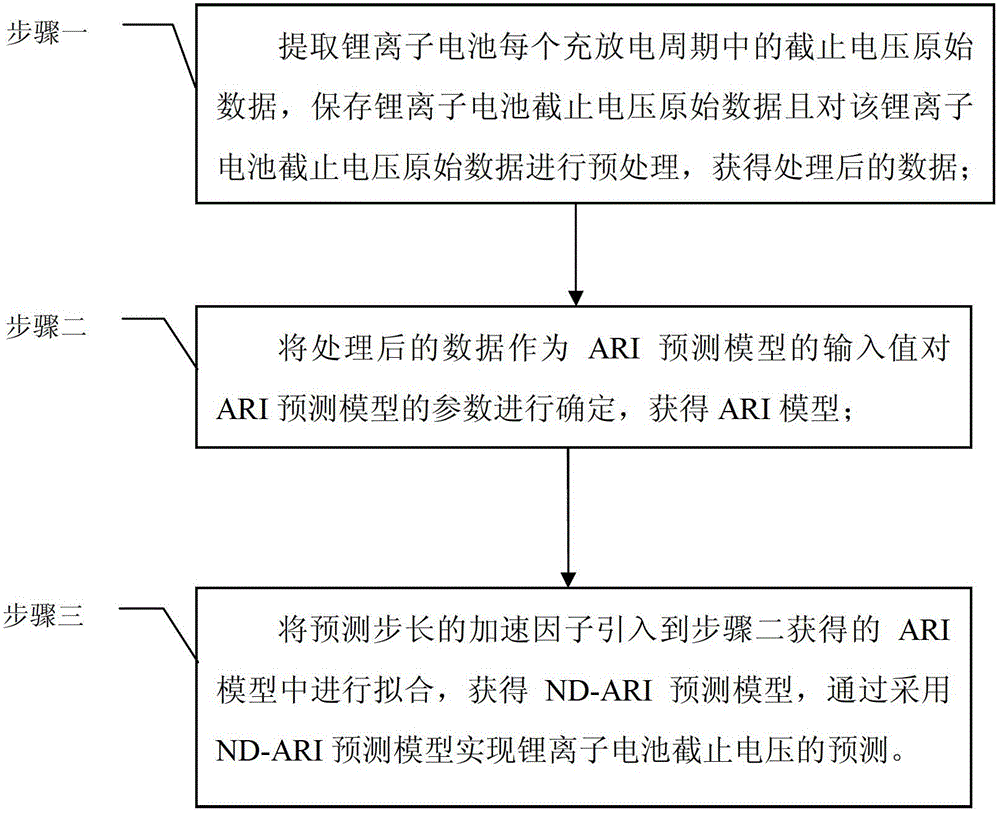

[0021] Specific implementation mode one: see figure 1 Illustrate this embodiment, the prediction method of the cut-off voltage of lithium-ion battery based on ARI algorithm described in this embodiment, its concrete steps are:

[0022] Step 1: Extract the original data of the cut-off voltage in each charge and discharge cycle of the lithium-ion battery, save the original data of the cut-off voltage of the lithium-ion battery and preprocess the original data of the cut-off voltage of the lithium-ion battery to obtain the processed data;

[0023] Step 2: Using the processed data as the input value of the ARI prediction model to determine the parameters of the ARI prediction model to obtain the ARI model;

[0024] Step 3: Introduce the acceleration factor of the prediction step into the ARI model obtained in step 2 for fitting, obtain the ND-ARI prediction model, and realize the prediction of the lithium-ion battery cut-off voltage by using the ND-ARI prediction model;

[0025] ...

specific Embodiment approach 2

[0031] Specific implementation mode two: see figure 1 Describe this embodiment, the difference between this embodiment and the method for predicting the cut-off voltage of a lithium-ion battery based on the ARI algorithm described in the first embodiment is that the cut-off voltage in each charge-discharge cycle of the lithium-ion battery is extracted in the first step Raw data, saving the original data of the lithium-ion battery cut-off voltage and preprocessing the original data of the lithium-ion battery cut-off voltage, the specific steps to obtain the processed data are:

[0032] Step 11: Measure the raw data of the cut-off voltage of the lithium-ion battery in each charge-discharge cycle several times, and extract the cut-off voltage at the end of each cycle of the lithium-ion battery from the raw data of the cut-off voltage of the lithium-ion battery to obtain the lithium-ion battery The raw data set of battery cut-off voltage {V k′}, where V k′ Indicates the cut-off ...

specific Embodiment approach 3

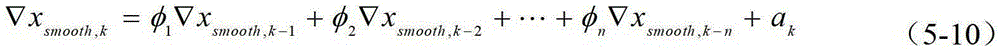

[0036] Specific implementation mode three: see figure 1 Describe this embodiment, the difference between this embodiment and the method for predicting the cut-off voltage of a lithium-ion battery based on the ARI algorithm described in Embodiment 1 or 2 is that the specific form of the ND-ARI prediction model is:

[0037] x k ={(1-B)[φ 1 x k-1 +φ 2 x k-2 +…+φ n x k-n ]+a k} / K T (5-9),

[0038] where x k is the lithium-ion battery cut-off voltage prediction value of the ND-ARI prediction model at time k, B is the backward shift operator, x k-n is the true value of the lithium-ion battery cut-off voltage at time k-n.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com