Electronically controlled fuel injection valve

A fuel injection valve, electronic control technology, applied in the direction of fuel injection device, charging system, engine components, etc., can solve the problem of fuel leakage to the combustion chamber, needle or valve plate damage, etc., to achieve opening and closing pressure increase, The effect of easy processing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The configuration and function of an embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. In addition, in describing the present invention, when it is judged that the detailed description of related known functions or configurations may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

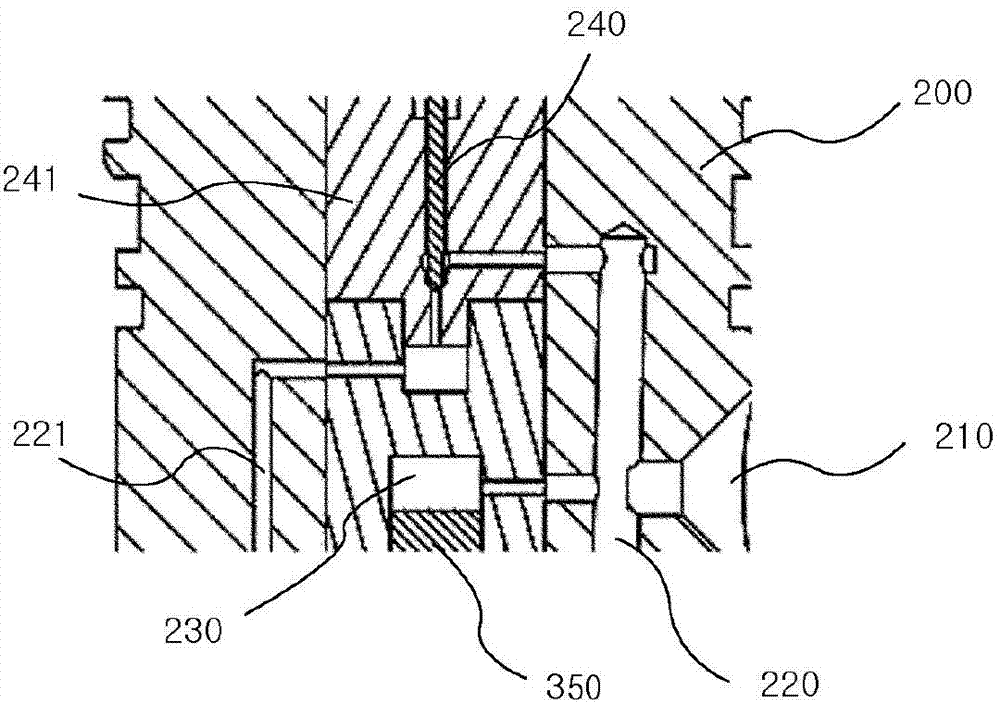

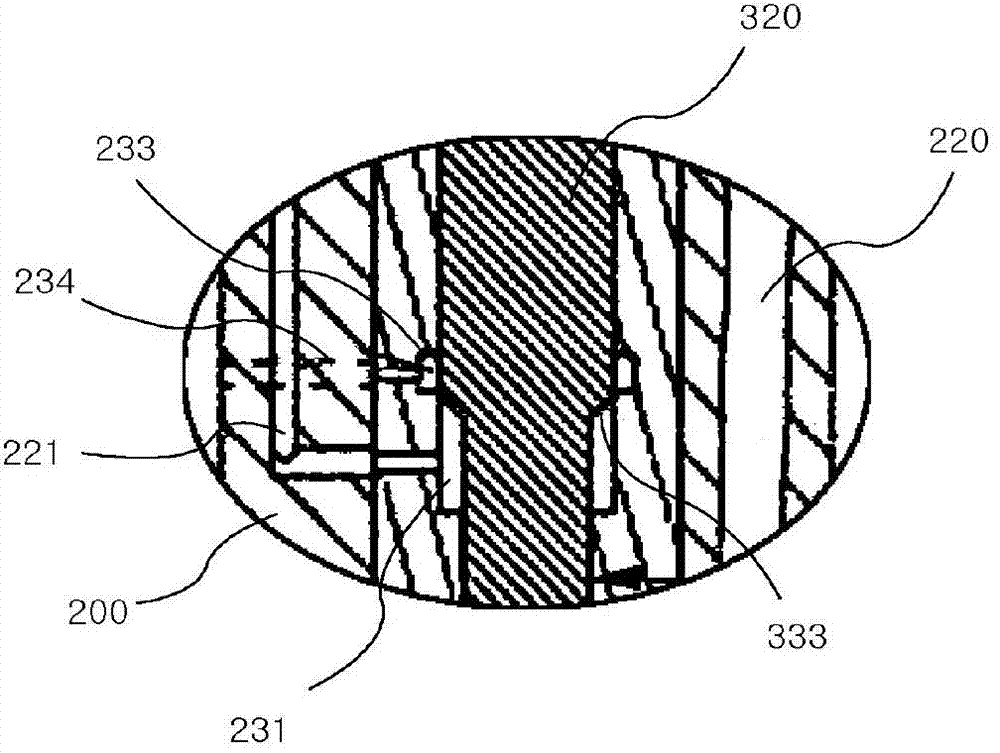

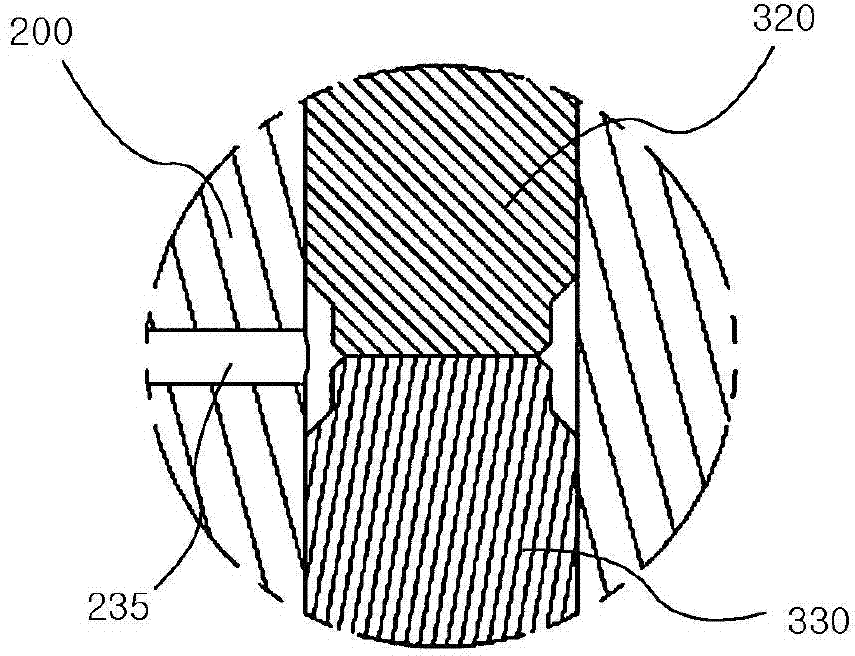

[0049] figure 1 is a schematic diagram showing a fuel injection valve according to a first embodiment of the present invention, figure 2 is a schematic diagram showing in detail the installation structure of the control needle of the fuel injection valve according to the first embodiment of the present invention, image 3 is a schematic view showing in detail the structure of the main shaft and the lower pressure chamber of the fuel injection valve according to the first embodiment of the present invention, Figure 4 It is a schematic diagram showing the fuel outflow hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com