Internally ventilated brake disk rotor

A brake disc and rotor technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of uneven heat transfer, uneven temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

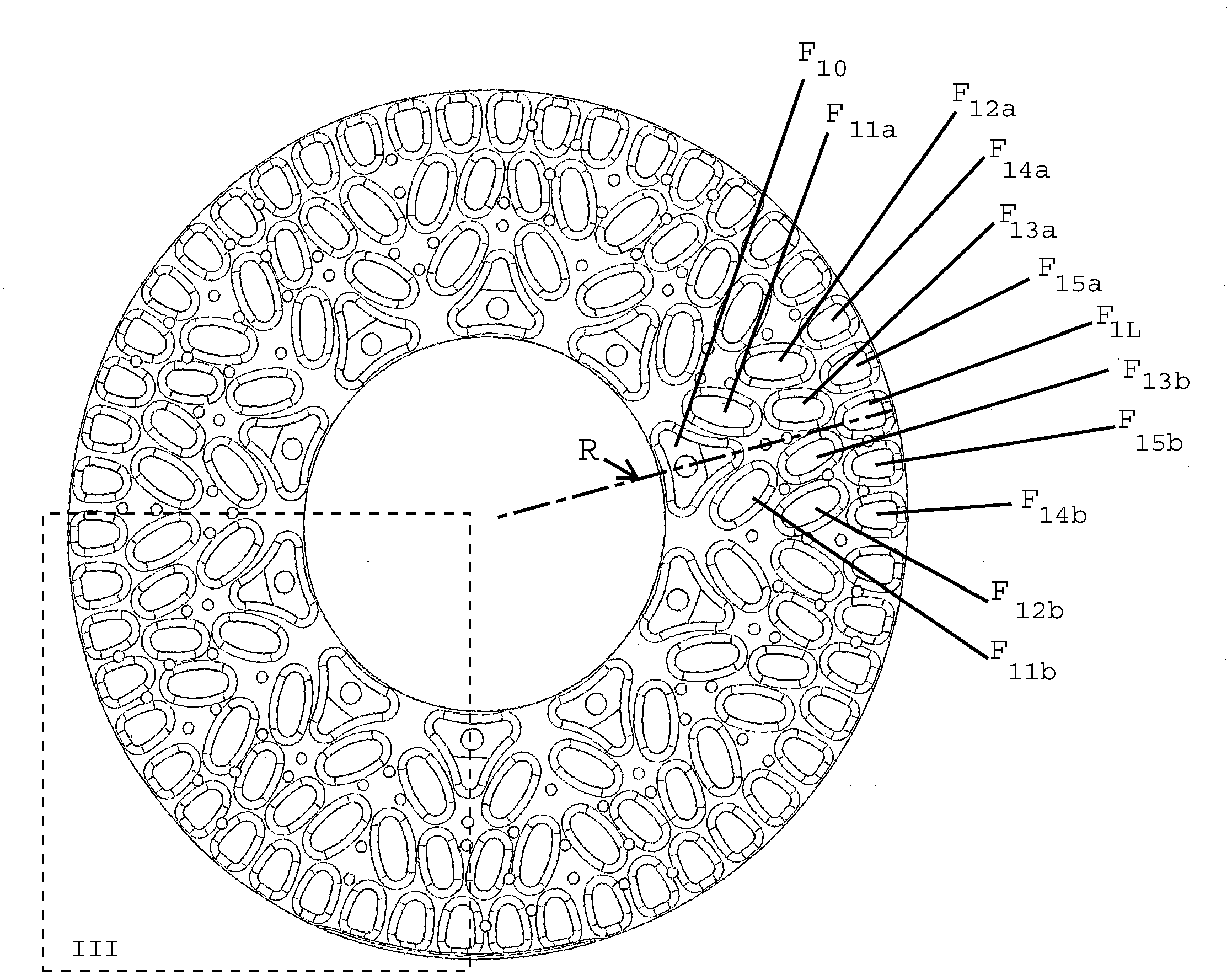

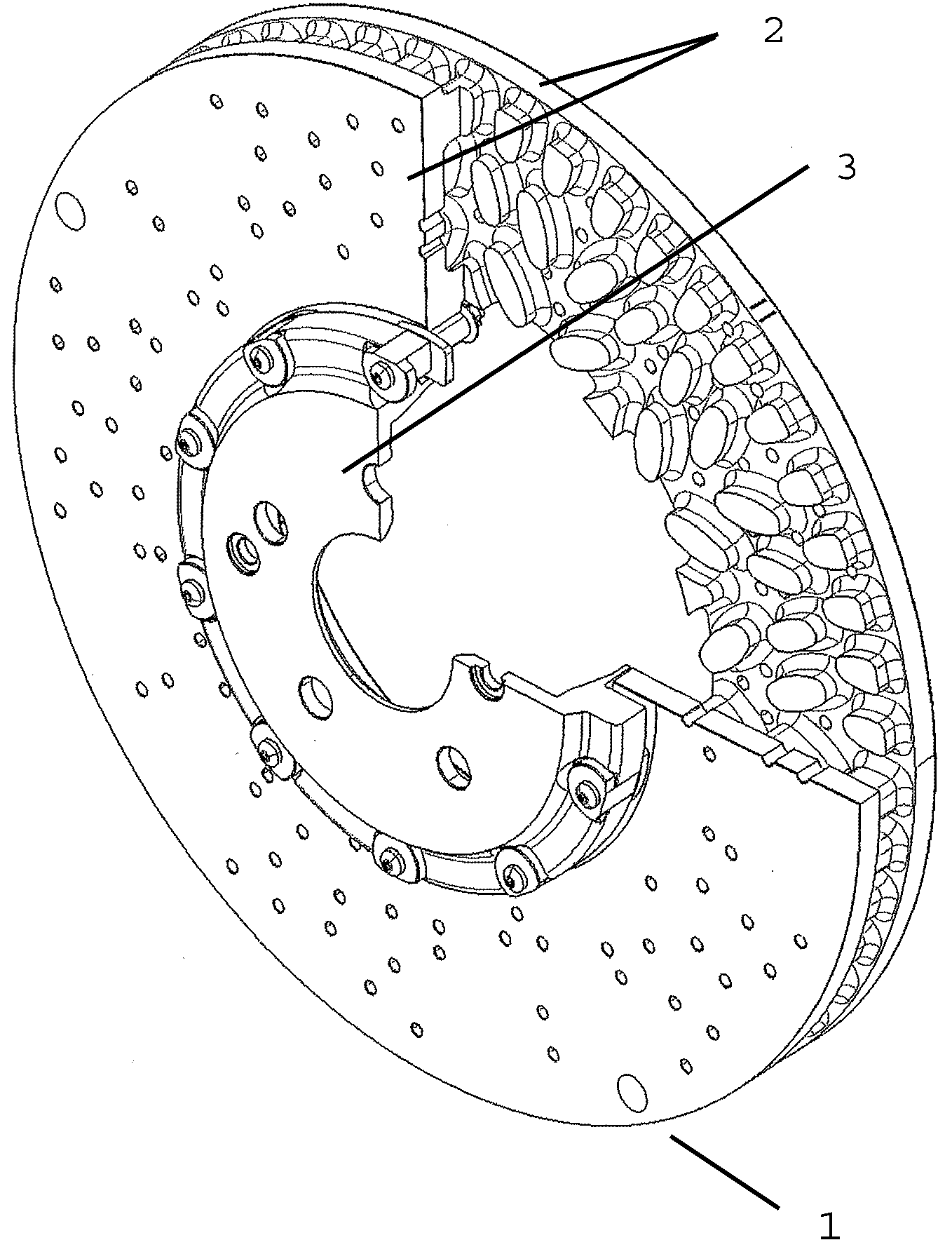

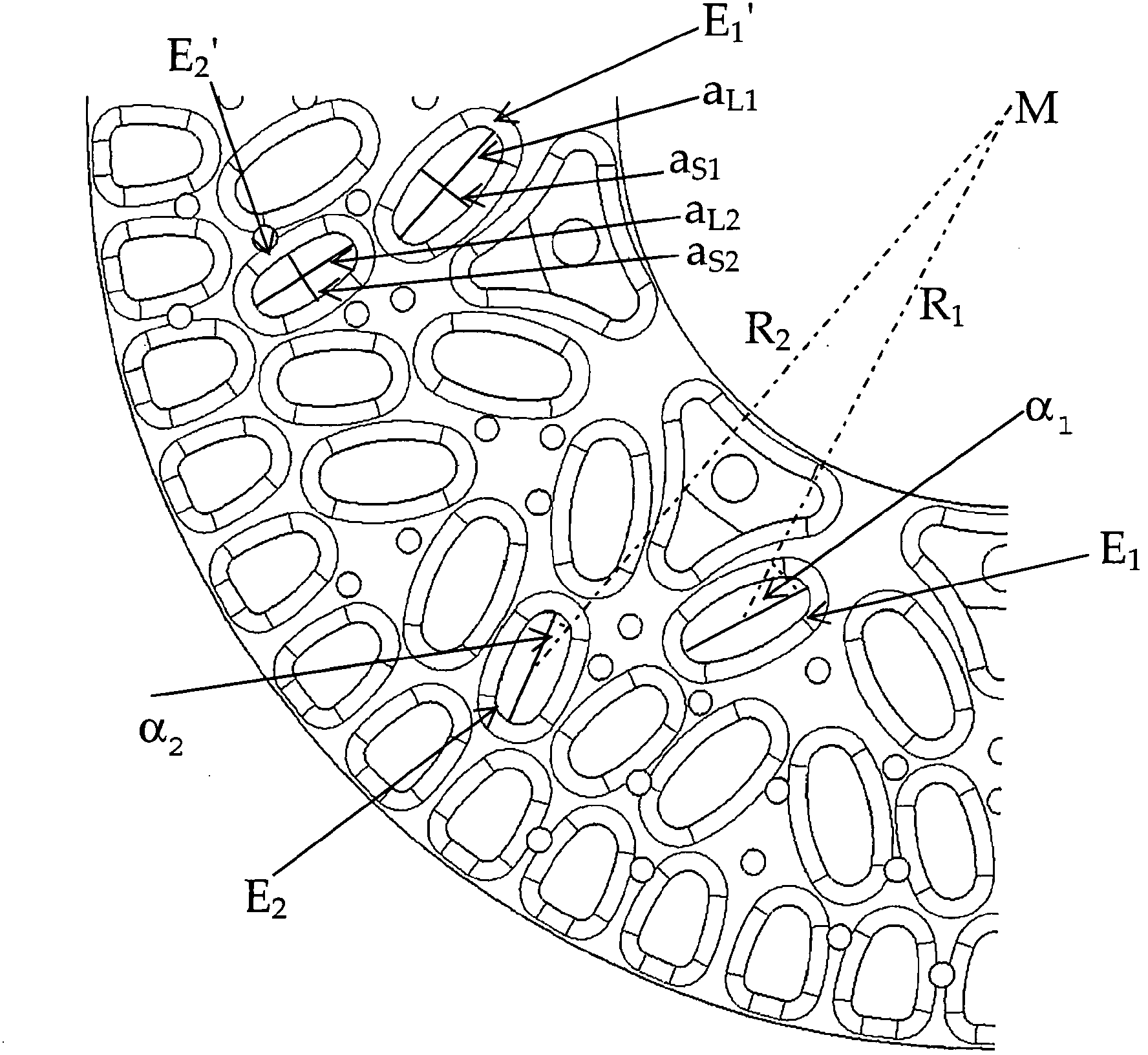

[0036] Experiments have been carried out to figure 1 A distinction is made between the represented design according to the invention and that described in the co-pending patent application EP10160307.4, in order to show, independently of the direction of rotation, the design according to the invention compared to the state of the art Improvement of the performance of the rotor ring. In both cases the material of the ventilated brake discs is the same carbon fiber reinforced silicon carbide ceramic material with a cooling channel height of 20mm, an overall thickness of 40mm, an outer diameter of 400mm and an inner diameter of 200mm. Both designs are optimized for a good uniformity of heat transfer on the surface of the brake disc rotor, which results in a uniform temperature distribution over the friction surface area of the brake disc, thereby also reducing heat transfer within the brake disc caused tension.

[0037] with the according to EP10160307.4 figure 1 The cooling...

example 2

[0042] In a further experiment, the heat transfer from the heated brake disc to the cooling air was evaluated in different directions of rotation. Using the same brake disc at the same initial temperature of 500° C. as in Example 1, the heat transfer was evaluated in terms of the temperature of the cooling air before and after passing through the cooling tubes and the mass flux of the cooling air.

[0043] The following data is obtained (direction of rotation: ccw=counterclockwise, cw=clockwise):

[0044]

[0045] As can be seen, operation of the brake disc rotor "comp." ("comparative example") in the wrong direction reduces significantly the heat transfer that can be achieved by rotating the disc in the correct direction of rotation by 22 % heat transfer efficiency. Brake discs according to the invention "Inv." ("Invention") have a slightly increased (+4%) heat transfer efficiency compared to rotating the disc rotor "comp." in a predetermined direction. Since the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com