Assembly tool for oil seal of four-drive front-axle rear cover of all-terrain vehicle

An all-terrain vehicle and assembly tooling technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of time-consuming, high labor intensity of workers, installation location and oil seal quality cannot be guaranteed, etc. The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

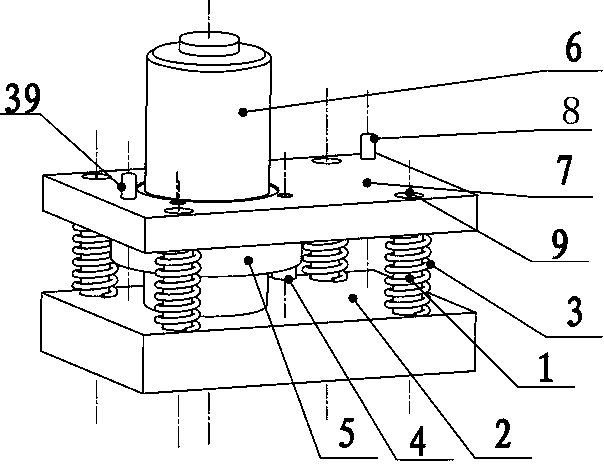

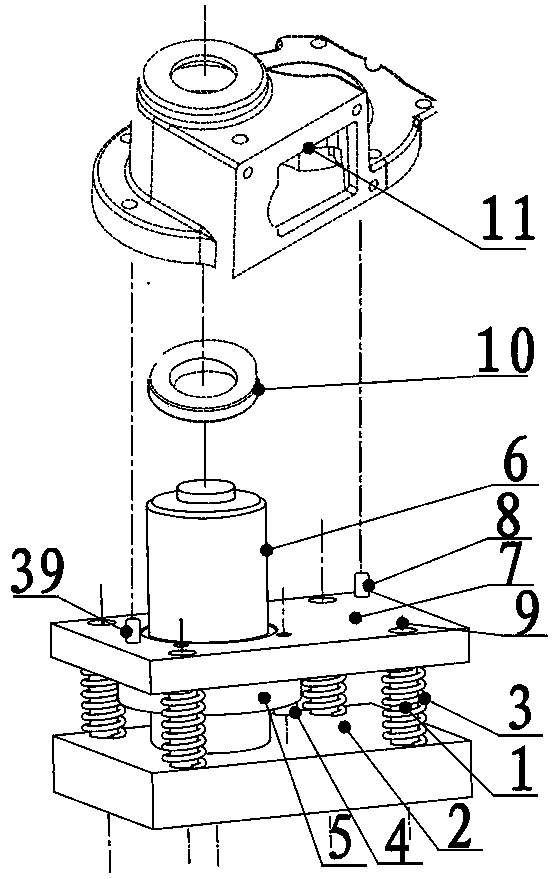

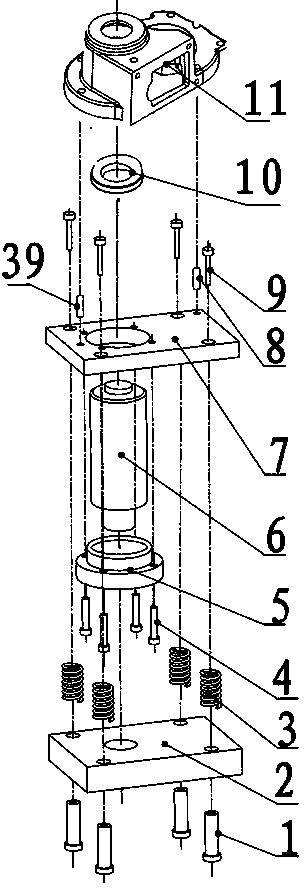

[0038] see Figure 1 to Figure 5 , all-terrain vehicle four-wheel drive front axle rear cover oil seal assembly tooling, which is mainly composed of sliding column 1, bottom plate 2, support spring 3, guide sleeve anti-loosening bolt 4, guide sleeve 5, support column 6, upper plate 7, right positioning pin 8. The sliding column connecting bolt 9 and the left positioning pin 39 are composed. The sliding column 1 is installed and run in the sliding column installation step hole 14 of the bottom plate 2, and the sliding column is installed in the sliding column connecting bolt installation hole 25 of the upper plate 7. The connecting bolt 9 is connected in the sliding column threaded hole 13 of the sliding column 1 at the same time, and the supporting spring 3 is set on the sliding column body 46 of the sliding column 1; The guide sleeve anti-loosening bolt 4 of the guide sleeve is installed in the guide sleeve anti-loosening bolt threaded hole 27 of the upper plate 7 at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com