Clamping device

A technology of clamping equipment and clamping parts, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of high cost, inability to achieve two-way, slipping or distortion, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

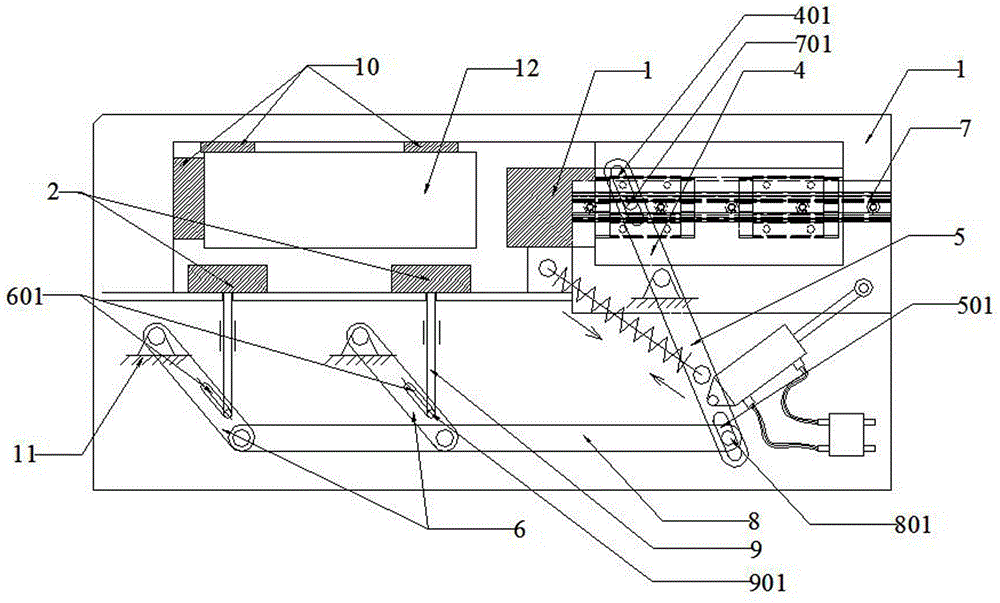

[0023] Embodiment: the cylinder drives the second guide rod, changes the angle relative to the slide rail 7 and moves the second guide rod upward, thereby driving the first guide rod to move upward, and the first slide groove 401 is inclined to the slide rail 7, so that the slide rail 7 Move toward the workpiece 12 to clamp the workpiece 12; the second guide rod drives the connecting rod 8 to move upward, thereby driving the third guide rod upward, and the third chute 601 is inclined to the guide rod 9, so that the guide rod 9 presses the workpiece 12 upward ; So as to achieve the purpose of two-way efficient clamping workpiece 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com