Displacement resolution refinement micro-nano operation platform based on lever drive

A technology of lever transmission and operation platform, which is applied in the direction of transmission device, machine platform/support, instrument, etc., can solve the problem of inability to realize resolution refinement, and achieve the effect of zero adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

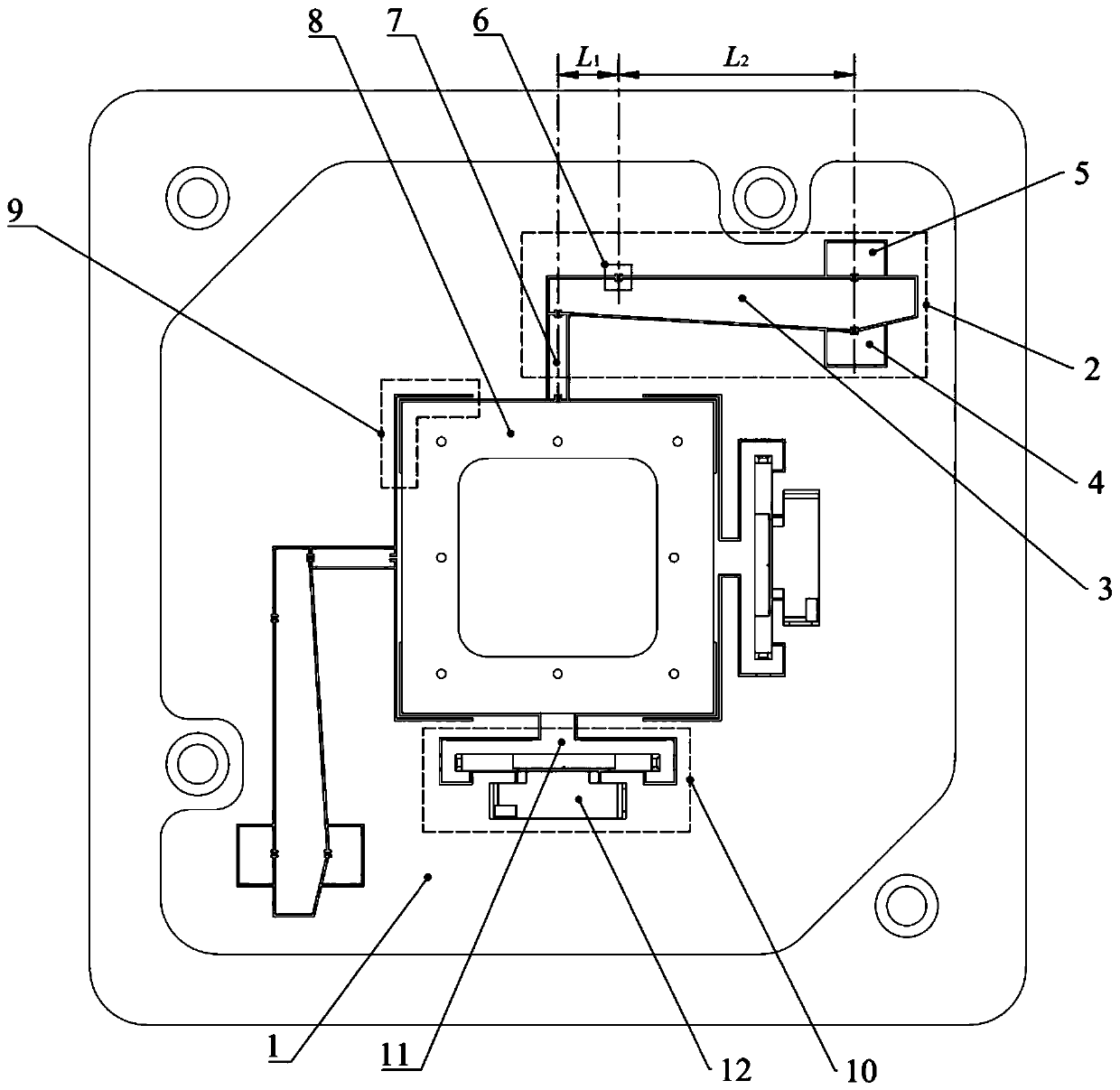

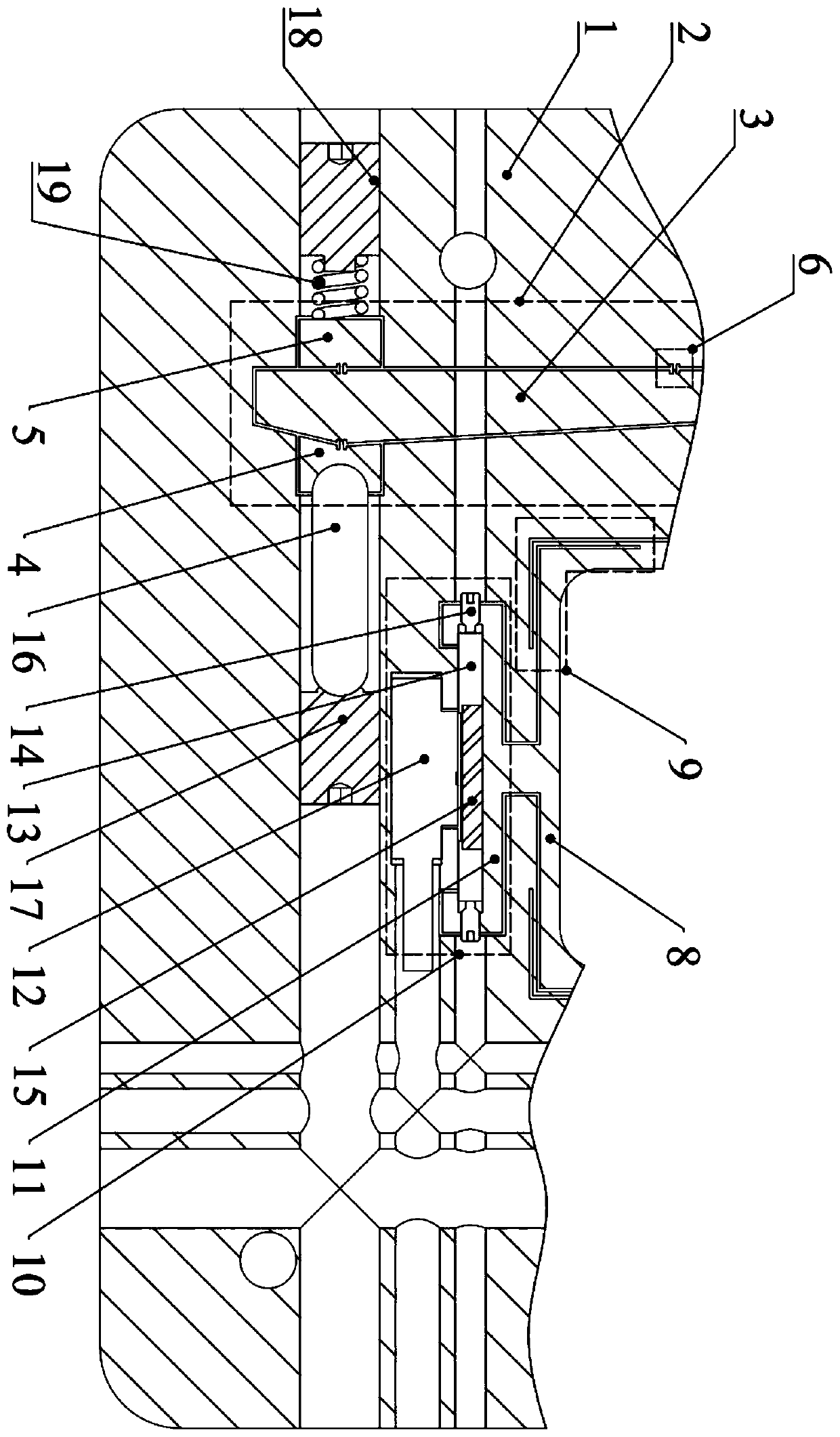

[0033] Such as figure 1 , 2As shown, the design method of the micro-nano operating platform based on the displacement resolution refinement of the lever transmission, the structure includes: the base body 1, the lever mechanism 2, the platform moving part 8, the platform guiding mechanism 9, the displacement measuring mechanism 10, and the piezoelectric ceramic actuator 16. Piezoelectric ceramic fastening nuts 17, pre-tightening nuts 18, and pre-tightening springs 19; the base body 1 is an aluminum alloy square block structure, and the upper position inside the base body 1 is provided with a lever mechanism 2 processed by wire cutting, and the lever mechanism 2 is formed by The lever 3, the first briquetting block 4, the second briquetting block 5, the support hinge 6, and the connecting rod 7 are composed. The lever 3 is designed as an equal-strength beam. 3 A first pressure block 4 is provided on the side where the thickness of one end changes near the edge of the base body...

Embodiment 2

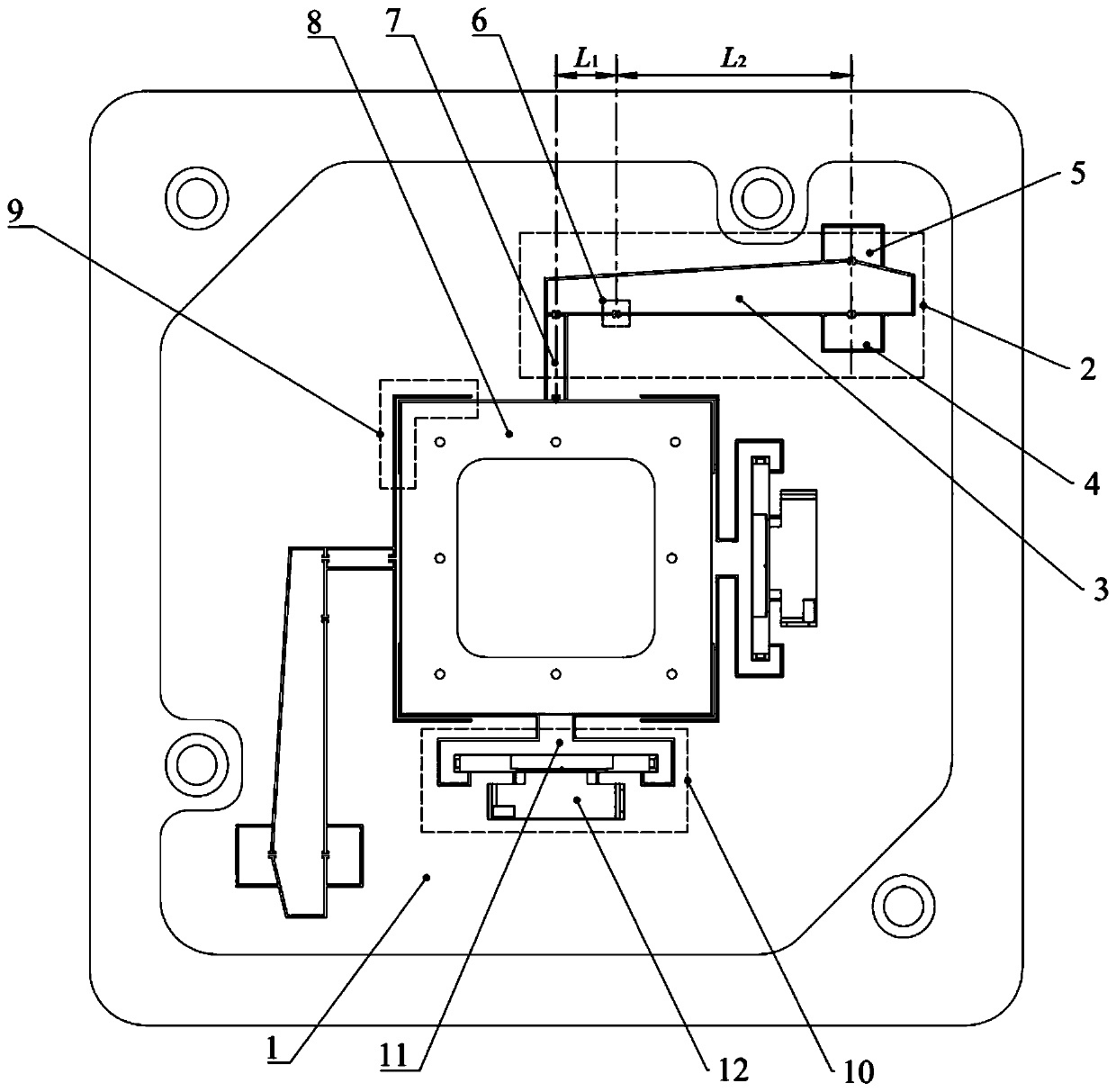

[0035] Such as image 3 As shown, the design method of piezoelectric ceramic driven micro-nano operating platform is refined based on the output displacement resolution of lever transmission. The structure includes: substrate 1, lever mechanism 2, platform moving part 8, platform guiding mechanism 9, displacement measuring mechanism 10, Piezoelectric ceramic actuator 16, piezoelectric ceramic fastening nut 17, pre-tightening nut 18, pre-tightening spring 19; the base body 1 is an aluminum alloy square block structure, and the upper position inside the base body 1 is provided with a lever mechanism 2 processed by wire cutting, The lever mechanism 2 is composed of a lever 3, a first briquetting block 4, a second briquetting block 5, a support hinge 6, and a connecting rod 7. The lever 3 is designed as an equal-strength beam, and the side of the lever 3 away from the moving part 8 of the platform is On the side where the thickness changes, the lever 3 is provided with a first pre...

Embodiment 3

[0037] Such as Figure 4 As shown, the design method of the voice coil motor-driven micro-nano operating platform is refined based on the output displacement resolution of the lever transmission. , the second fastening bolt 23, the connecting mechanism 24, the connecting block 25, the first guiding mechanism 26, the second guiding mechanism 27, the lever mechanism 2, the platform moving part 8, the platform guiding mechanism 9; the base body 1 is an aluminum alloy square block structure , the inner side of the substrate 1 is provided with a wire-cut square cavity for accommodating the stator 20 of the voice coil motor, and the bottom of the square cavity is provided with two symmetrically distributed circular through holes for accommodating the first fastening bolts 22, The first fastening bolt 22 cooperates with the threaded hole at the end of the voice coil motor stator 20 through the circular through hole, the voice coil motor mover 21 is located in the voice coil motor sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com