Easy-to-use press take-up roll assembly

A technology of printing machine and roll paper roll, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of poor clamping stability, small application range, easy deviation of paper core, etc., and achieve extended use Longevity, anti-deviation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

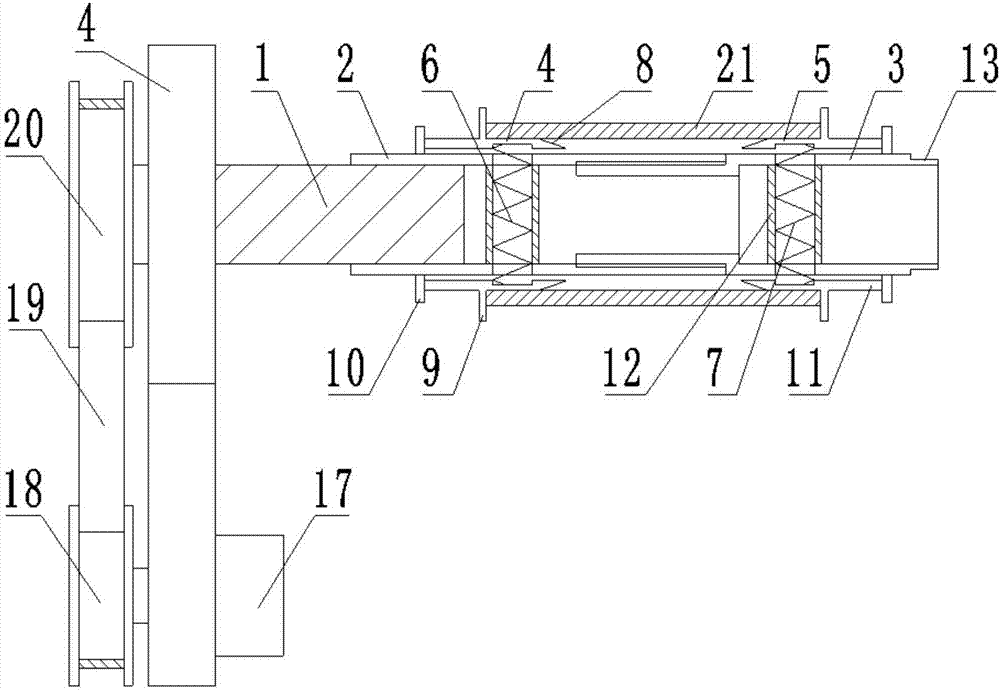

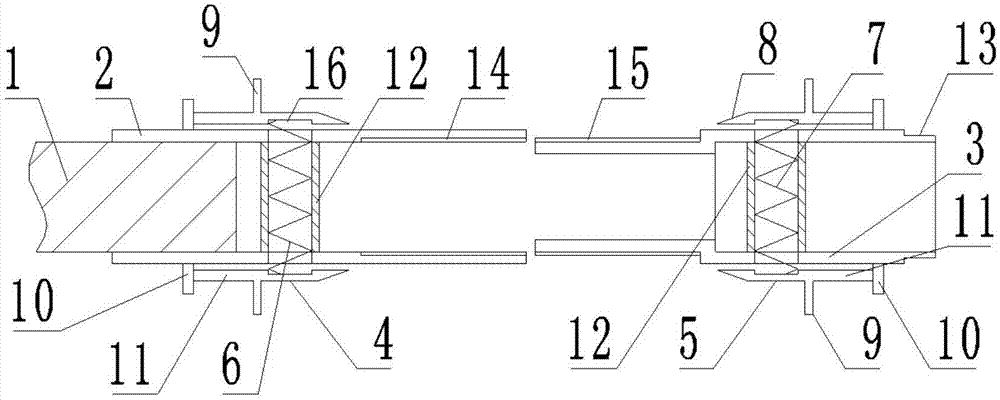

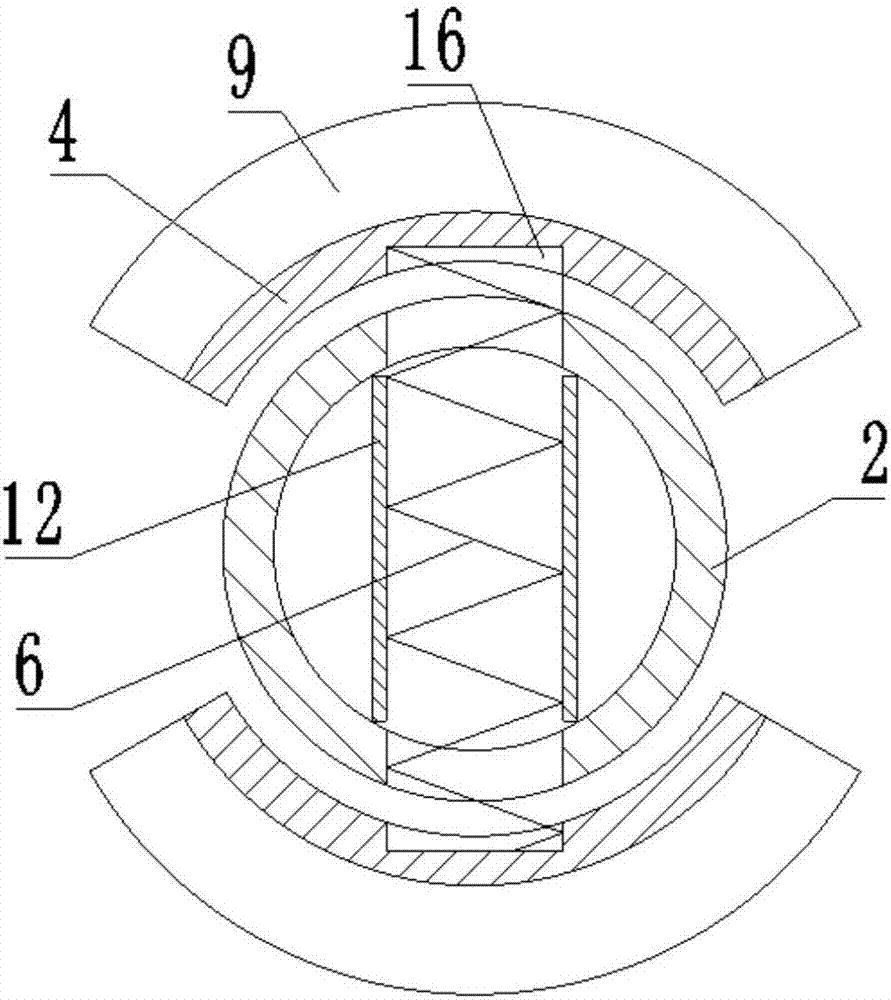

[0020] Example. Easy-to-use press take-up roll assembly, constructed as Figures 1 to 3 As shown, it includes a rotating shaft 1, and one end of the rotating shaft 1 is connected with a fixed reel 2; An arc-shaped fixed fastening tile 4 and a movable fastening tile 5; a first spring 6 is connected between the two fixed fastening tiles 4, and a second spring 7 is connected between the two moving fastening tiles 5.

[0021] One end of the fixed fastening tile 4 close to the mobile fastening tile 5 and one end of the mobile fastening tile 5 close to the fixed fastening tile 4 are provided with a slope 8, and the other end of the fixed fastening tile 4 and the mobile fastening tile The other end of 5 is provided with baffle plate 9. Both the fixed reel 2 and the movable reel 3 are connected with a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com