Brush with detergent

A detergent and brush technology, applied in the field of brushes with detergent, can solve the problems of wasting cleaning supplies, wasting water, time-consuming, labor-intensive and labor-intensive, and achieve the effects of saving environmental protection, overall coordination, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

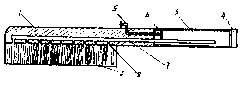

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] In the view, under the front end of the brush body 1 is the brush 2, the rear end is the internal cleaning agent chamber 3, the upper middle part is provided with a hand pressure handle 5, the bottom end is provided with a cleaning agent chamber 3 sealing cap 4, and the cleaning agent chamber 3 There is a push valve 6 connected to the hand pressure handle 5 and an agent outlet pipe 8 that goes straight to the root of the brush 2. The agent outlet pipe 7 is located at the root of the brush and is provided with a cleaning agent injection hole 8. When using, first open the cleaning agent chamber The sealing cap 4 of 3 fills the cleaning agent into the cleaning agent chamber 3, and the sealing cap 4 is tightly closed. When scrubbing the articles, press the hand pressure handle 5, push the valve 6 to press the cleaning agent volume, and the cleaning agent will flow out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com