Intravascular stent applied to interventional operation as well as use method, manufacturing method and manufacturing device of intravascular stent

A vascular stent and interventional surgery technology, applied in the field of vascular stents, can solve problems such as poor durability, failure of surgery, blocking blood, etc., and achieve the effect of improving fatigue safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

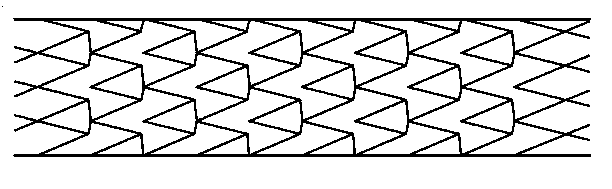

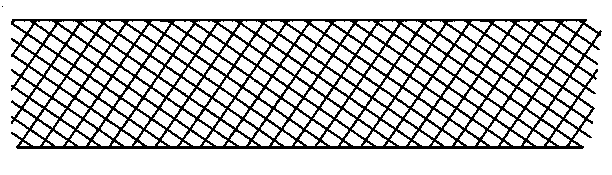

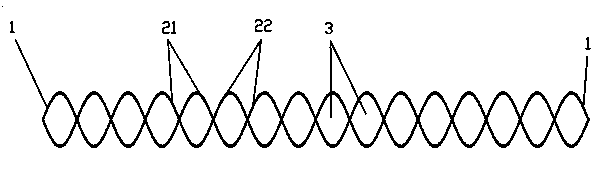

[0038] The invention discloses a self-expanding stent for interventional surgery formed by braiding biocompatible metal wires (such as nickel-titanium alloy wires), which consists of a ( image 3 shown) or multiple ( Figure 4 to Figure 7 As shown) nickel-titanium alloy wires 2 are wound and formed by interlacing with each other at an axial offset of a certain angle in the length direction of the whole stent. It should be noted that: the present invention only takes nickel-titanium alloy wire as an example, and its cross-sectional shape can be circular, elliptical, trapezoidal, rectangular, or others; of course, the nickel-titanium alloy wire can also be replaced by other alloy wires, For example: stainless steel 316, etc.

[0039] The blood vessel stent wound by nickel-titanium alloy wire includes a cylindrical body 4 and rounded corners 1 arranged at both ends of the body 4. The body is made of nickel-titanium alloy wire through forward rotation and reverse rotation Stagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com