Lift cable tension measuring method and device

A measuring device and rope technology, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problem of large errors and achieve easy and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, based on embodiment of this invention, it demonstrates concretely with reference to drawings.

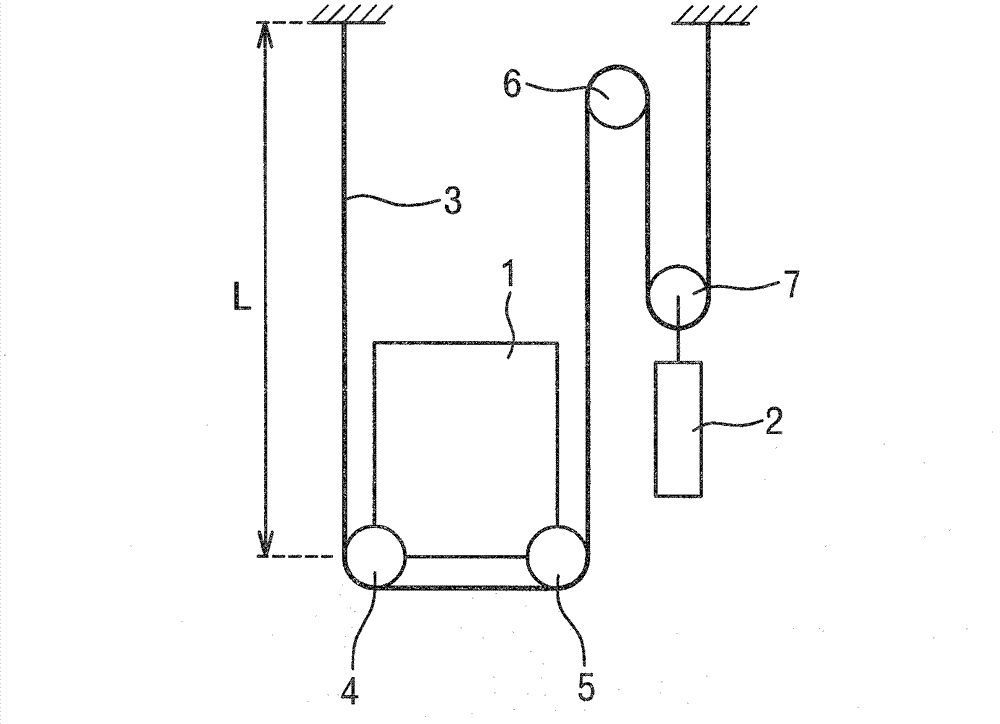

[0034] The cable tension measuring device involved in the present invention is for such as figure 1 A device for measuring the tension of the main rope 3 in the elevator as shown.

[0035] exist figure 1 In the shown elevator, a plurality of (n) main pulleys are wound around the pulleys 4 and 5 mounted on the elevator car 1, the pulley 7 mounted on the counterweight 2, and the pulley 6 connected to the drive motor (not shown). ropes 3, and the elevator car 1 and the counterweight 2 are suspended by these multiple (n) main ropes 3, and the pulley 6 is rotationally driven by the driving motor, thereby lifting the elevator car 1 drive.

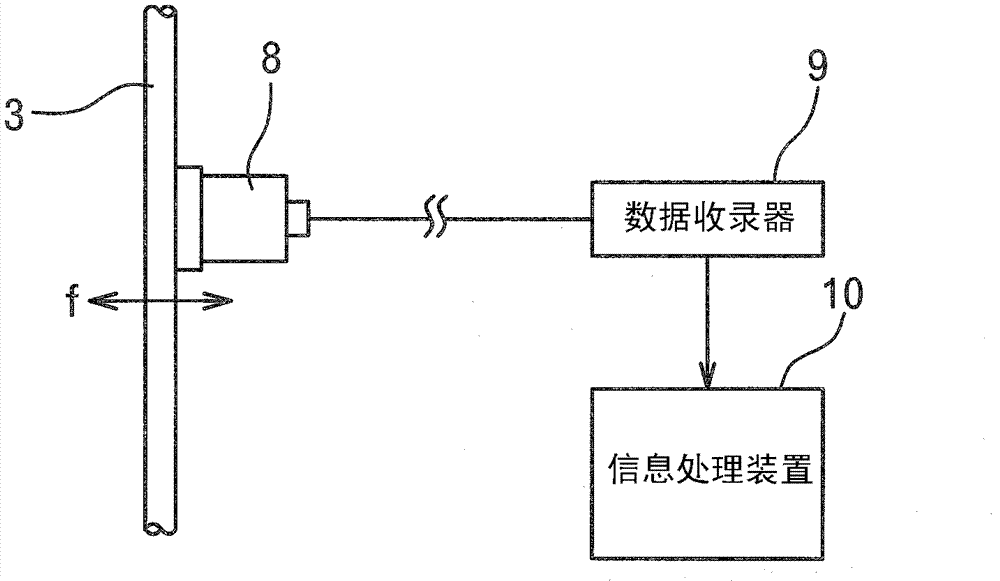

[0036] The cable tension measuring device involved in the present invention, such as figure 2 Shown, comprise: acceleration sensor 8, it is installed on each main rope 3, and detects the vibration of main rope 3; Data recorder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com