Tolerance test template for master node of ship hull and detection method thereof

A master node and template technology, applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve problems such as inaccuracy and no measurement basis for node angles, and achieve the effect of ensuring construction tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

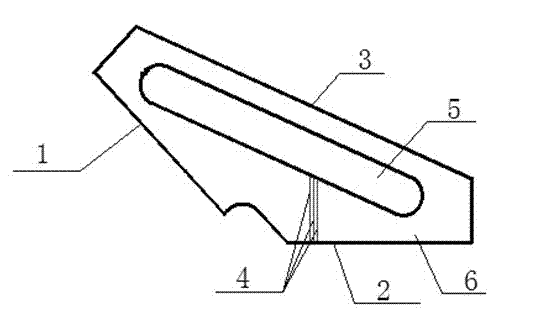

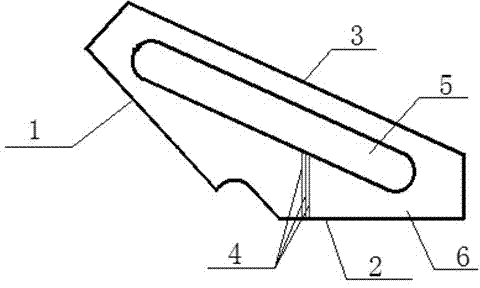

[0022] see figure 1 , figure 1 It is a structural schematic diagram of the main node tolerance inspection template of the present invention. As shown in the figure, a tolerance inspection template for the main node of the hull includes the first angle side 1, the second angle side 2 and the hypotenuse 3, and the gap between the two angle sides There is a certain angle, and three scale lines are arranged above the first angle side, the middle scale line is the theoretical scale line, and the scale lines on both sides are the range scale lines allowed by the tolerance inspection standard. There is a hole 5 in the center of the template.

[0023] When manufacturing the hull main node tolerance inspection template of the present invention, the sideline name 6 should be clearl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com