Zero-charge starting and stopping circuit of inverter

A technology of stop circuit and inverter control circuit, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of inverter bridge arm interference conduction, electrical arcing, risky competition of the main circuit, etc., to eliminate device out of control , Eliminate electrical arcing and avoid associated damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

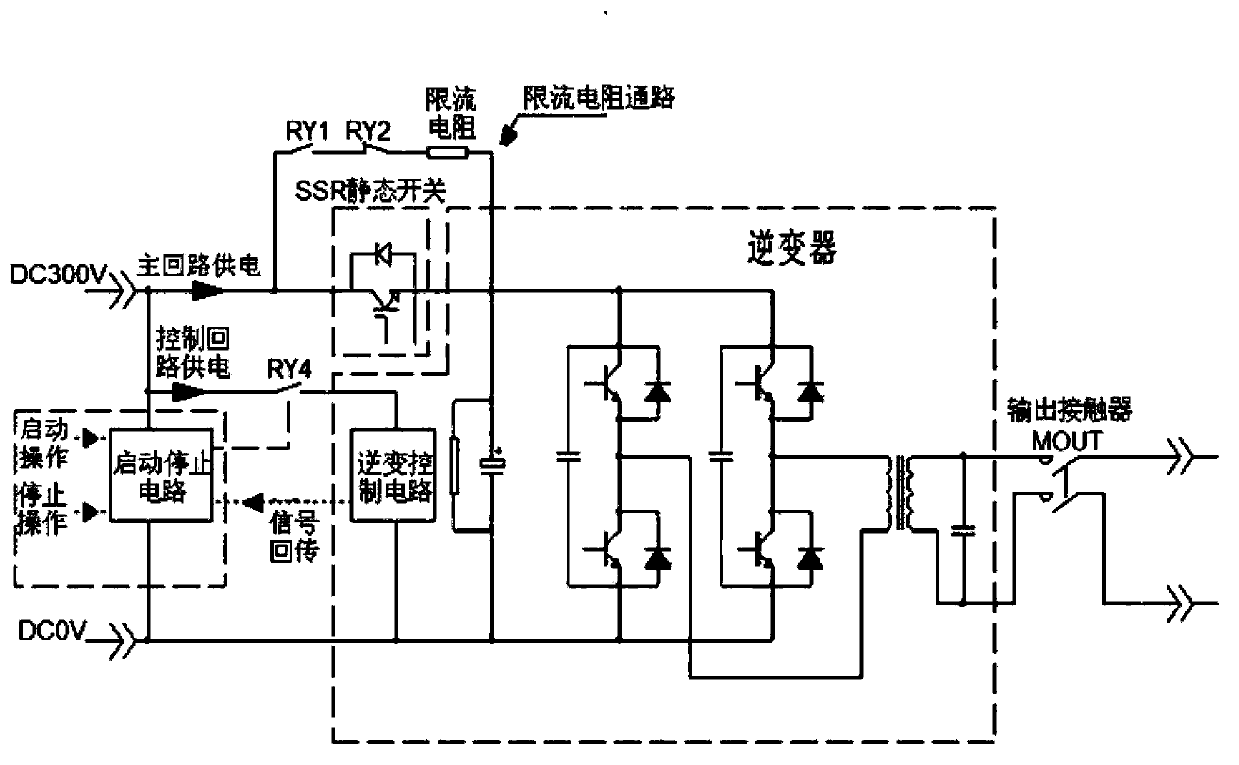

[0033] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings,

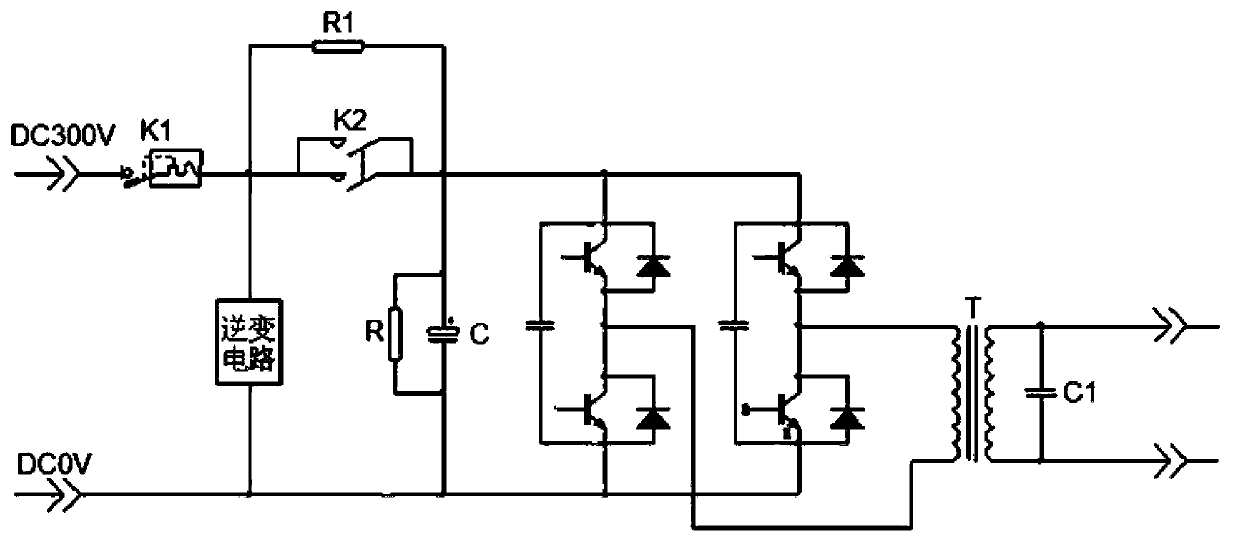

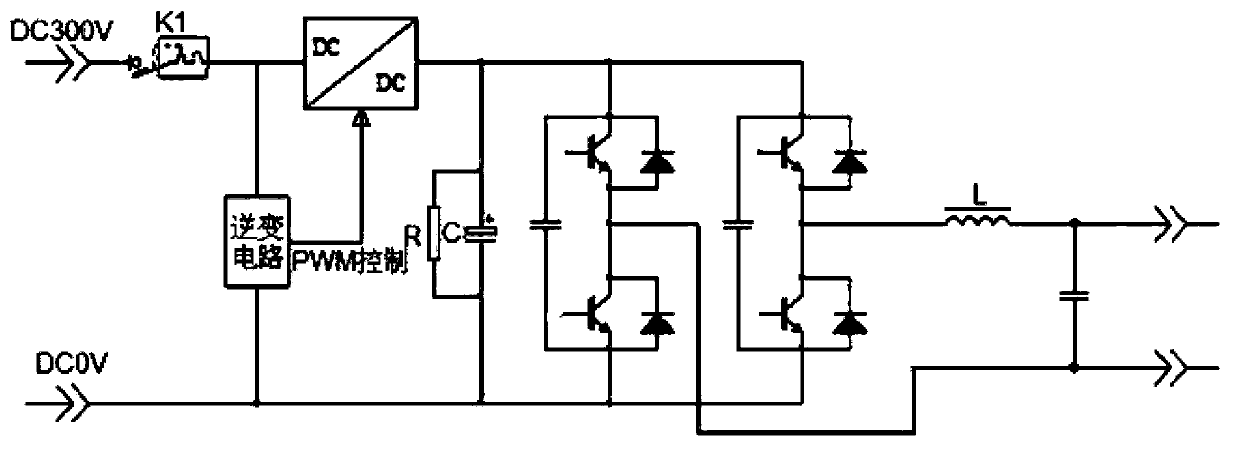

[0034] An inverter zero-charge start and stop circuit, such as image 3 As shown, including the current limiting resistance of the inverter, the DC bus capacitor, and the inverter control circuit, the innovation of the present invention is that it divides the power supply of the inverter into two parts, the main loop power supply and the control loop power supply. Loop power supply is to connect a circuit connected in series with relays RY1 and RY2 on the node between the positive terminal of the power supply and the current limiting resistor, and connect an SSR static switch to the node between the positive terminal of the power supply and the current limiting resistor and the DC bus capacitor to realize the main circuit Power supply control, the power supply of the control loop is to connect the start-stop circuit between the positive and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com