Position detecting tool for shifting fork pocket of synchronizer gear sleeve

A synchronizer and shift fork groove technology, which is applied in the field of synchronizer gear sleeve shift fork groove position inspection tools, can solve the problems of troublesome detection, affecting detection efficiency, and the inability to detect two upper and lower surfaces at the same time, so as to achieve simple detection and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

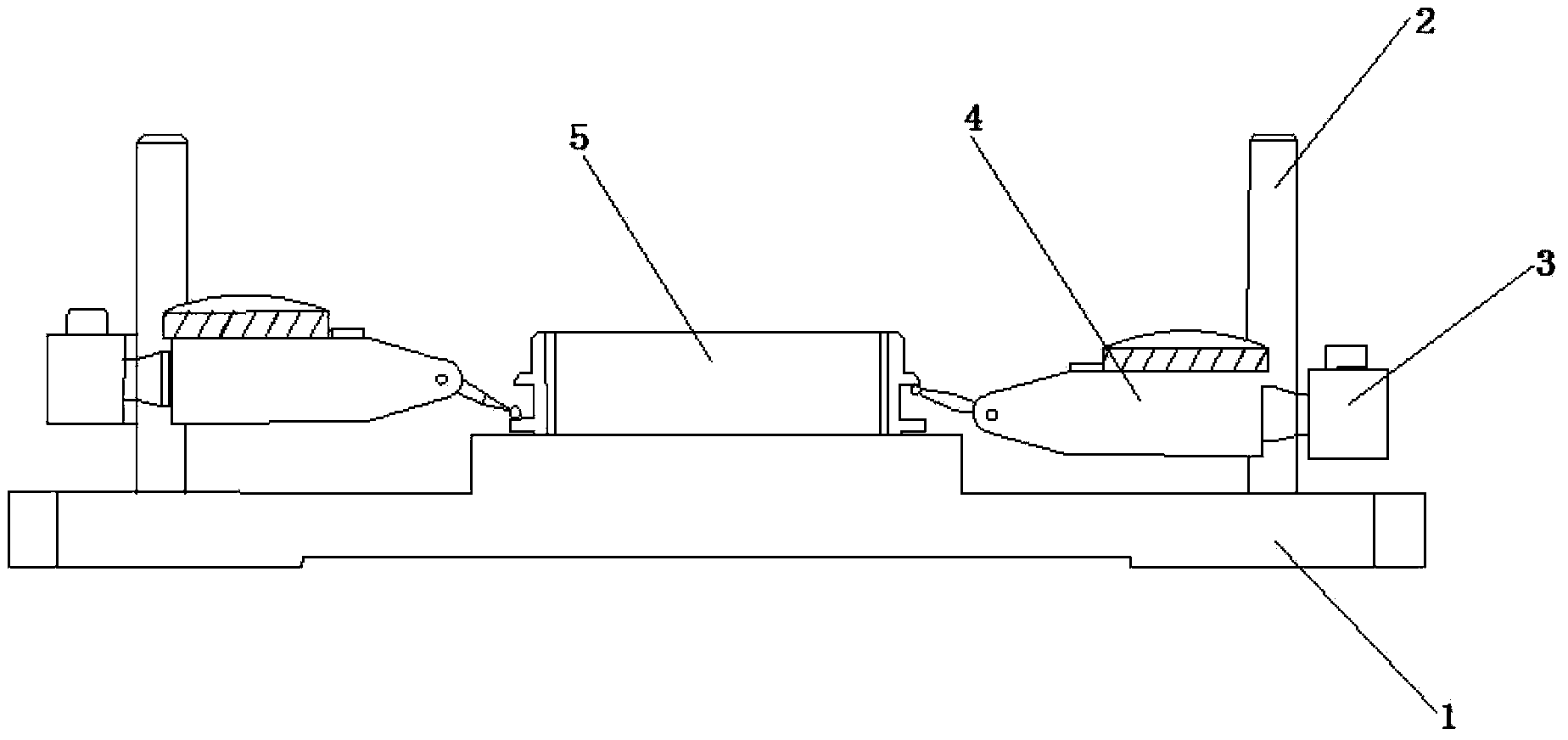

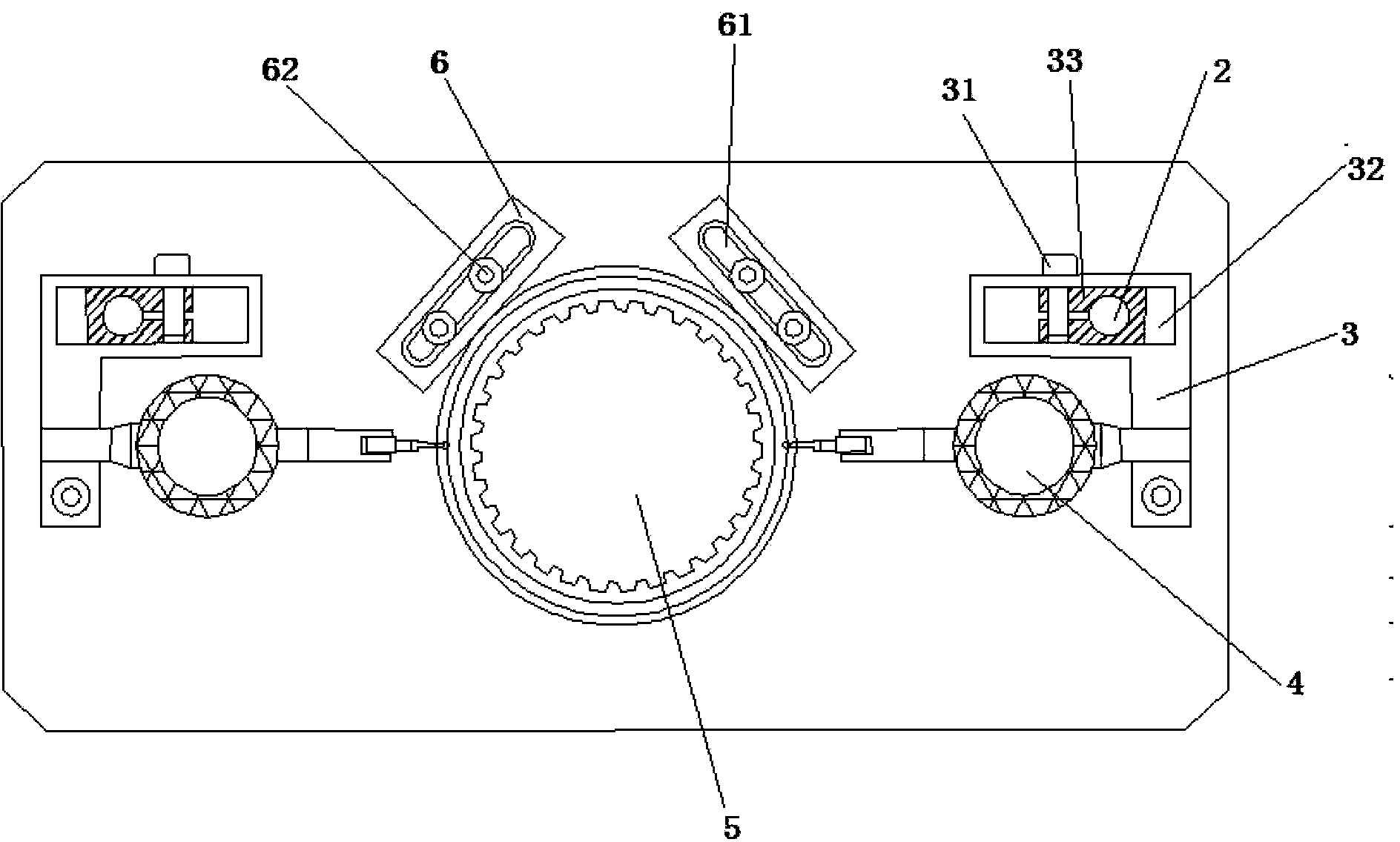

[0017] The invention describes a synchronizer gear sleeve shift fork groove position detection tool, and its specific implementation structure is as follows figure 1 , figure 2 As shown, including the base 1, the base 1 has a positioning mechanism and two sets of detection tools with the same structure,

[0018] The detection tooling includes the guide post 2, the guide mechanism and the rod gauge 4 connected in sequence. The guide mechanism can make the rod gauge 4 move horizontally, move up and down along the guide post 2 and rotate around the guide post 2 and fix the rod gauge 4 and the guide post 2 ;

[0019] The guide post 2 is fixed on the base 1;

[0020] The positioning mechanism limits the synchronizer gear sleeve 5 to the detection head of the two rod gauges 4, which can simultaneously detect the upper and lower inner surfaces of the shift fork groove on the synchronizer gear sleeve 5 and the synchronizer gear sleeve 5 can rotate around its axis. within the area....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com