A chamfering grinding wheel and chamfering method for processing thick-layer epitaxial silicon single wafer

A silicon single wafer and chamfering technology, which is used in metal processing equipment, machine tools suitable for grinding workpiece edges, manufacturing tools, etc., can solve the problems of rough edges of silicon single wafers and failure to completely eliminate the rough shape of rough chamfers. , to achieve the effect of good edge quality consistency, elimination of adverse effects, and high edge contour accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

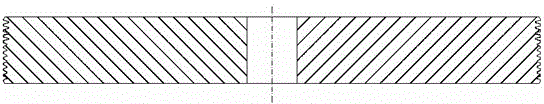

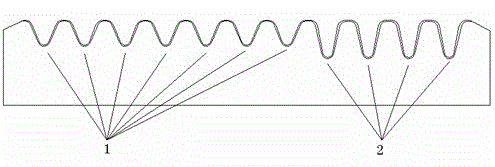

[0016] The present invention will be further explained below with reference to the drawings and embodiments: figure 1 with figure 2 In this embodiment, the rough-chamfered grinding wheel groove and the fine-chamfered grinding wheel groove are made on the same chamfered grinding wheel (the rough-chamfered grinding wheel and the fine-chamfered grinding wheel can also be made respectively). The chamfered grinding wheel contains seven rough chamfers. Grinding wheel groove 1 and four fine chamfering grinding wheel grooves 2, the chamfering grinding wheel is installed on the main shaft of the chamfering machine through the shaft hole, the chamfering machine is a general equipment in the industry.

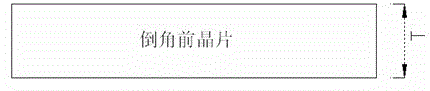

[0017] image 3 For the shape of the silicon single wafer before chamfering, it can be seen that the edge of the silicon single wafer is a right-angled structure before chamfering, which is prone to chipping. Therefore, the edge of the silicon single wafer must be chamfered.

[0018] Reference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com