Glass putting device

A technology for placing devices and glass, applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problems of occupying a large space, easy to bend and damage, frequent movements, etc., to reduce movement waste, reduce friction, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

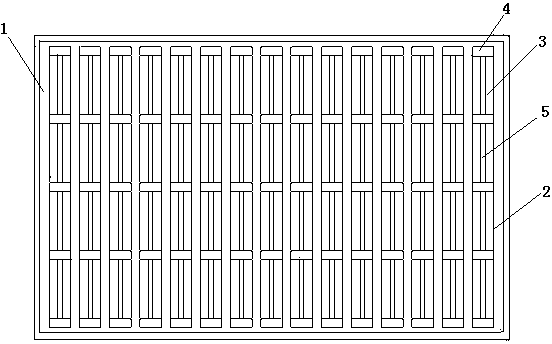

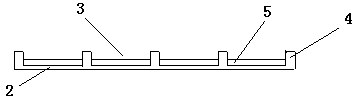

[0016] Such as figure 1 and figure 2 The shown glass placement device includes a base 1 and a blister tray 2. The base 1 is a hollow box structure without a cover. There are 20 blister trays 2 inside the base 1 box, and each blister tray 2 is sequentially There are 5 equally spaced retaining bars 4, and a storage compartment 3 is formed between two adjacent retaining bars 4, and a small boss 5 with a height of 1 cm is provided at the bottom of each placement compartment 3, and the good products that pass the electrical test The glass is sequentially discharged into the blister tray 2 and placed on the small boss 5. Each storage compartment 3 can place 20-25 pieces of glass. The plastic trays 2 are separated to avoid collisions during transportation.

[0017] Originally, when using ordinary blister trays 2 to place glass, 80-120 blister trays 2 are used for each batch of goods, but only 1-2 chassis are needed for each batch of goods after the present invention is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com