A mechanism that cooperates with a manipulator to realize automatic product loading and unloading

An automatic pick-and-place, manipulator technology, applied in the direction of manipulator, program-controlled manipulator, conveyor objects, etc., can solve problems such as hidden dangers, achieve position accuracy, extensive commonality of mechanisms, solve hidden dangers and some unstable factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

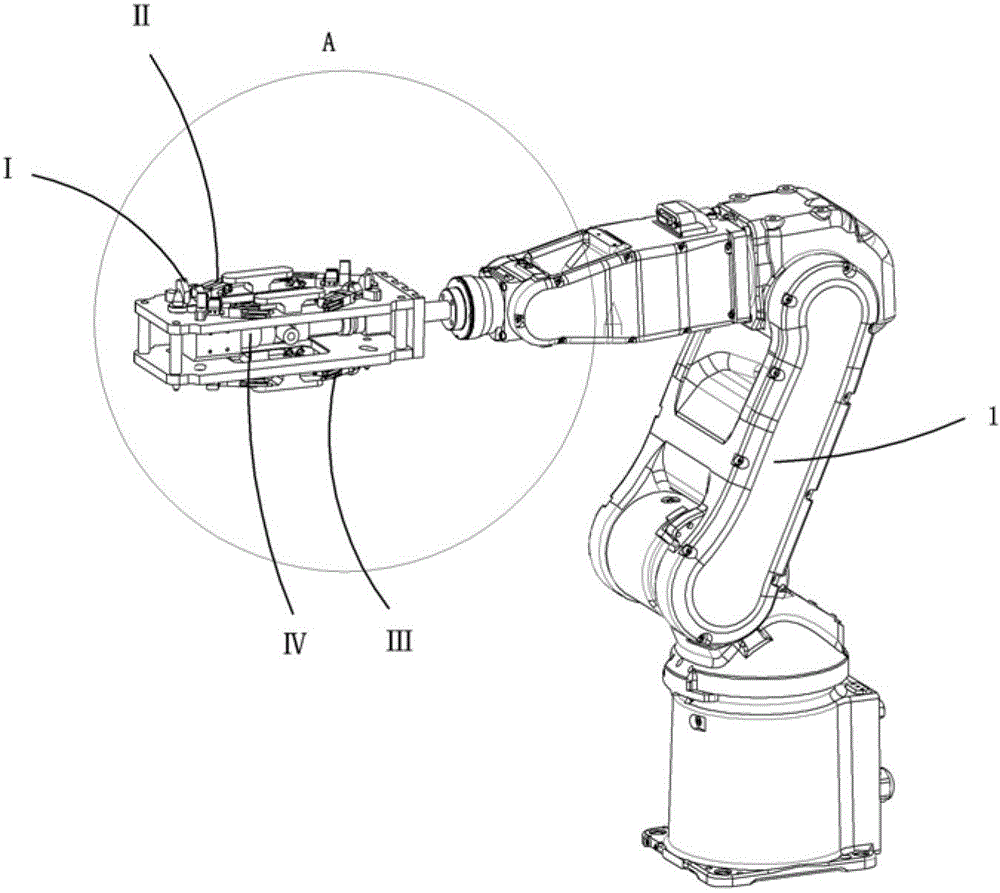

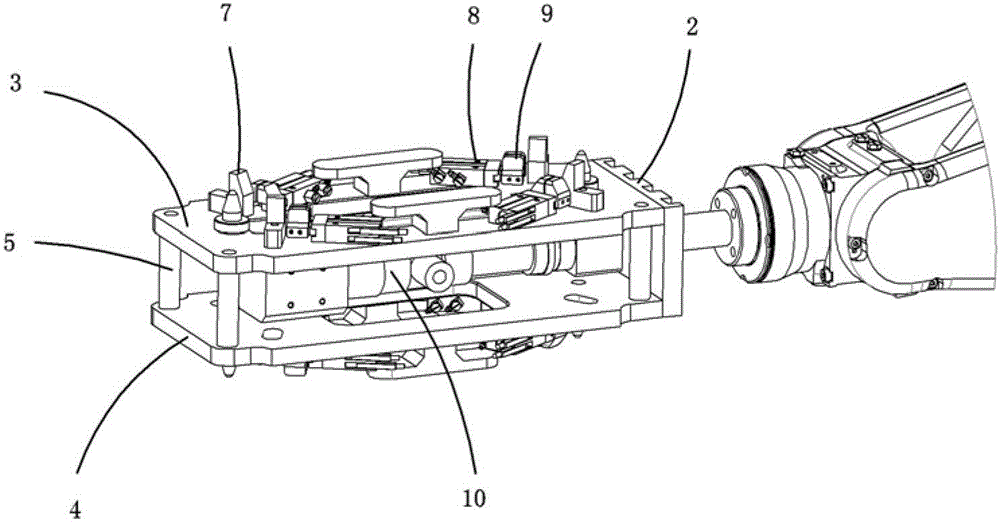

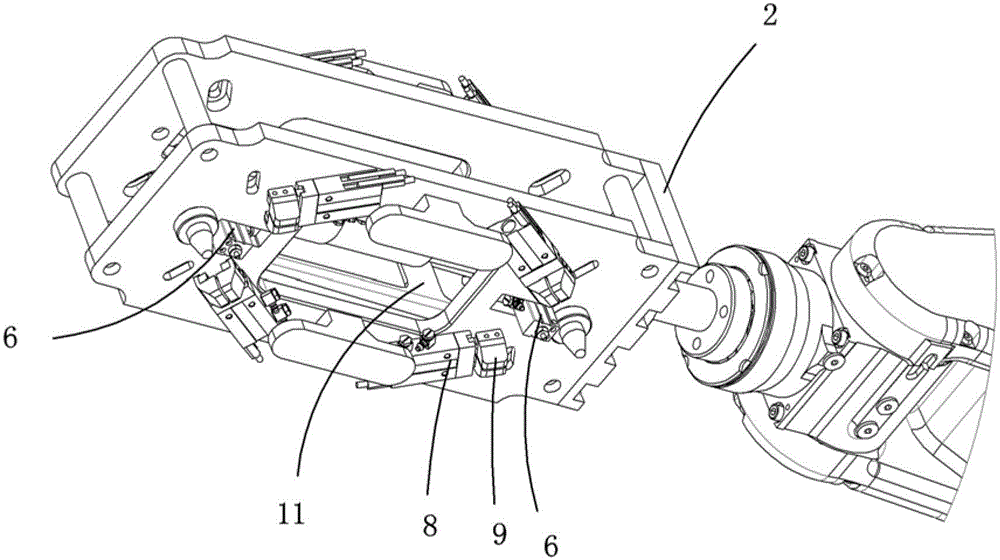

[0017] Examples, see attached Figure 1~3 , a mechanism that cooperates with a manipulator to automatically pick and place products, which includes a manipulator 1, a connecting plate 2, a fixed plate a3, a fixed plate b4, a support column 5, a cylinder 6, a product guiding mechanism Ⅰ, a semi-finished product gripping mechanism Ⅱ, a finished product Clamping mechanism III and camera photo detection mechanism IV, the front end of the manipulator is equipped with a connecting plate, and the manipulator can drive the connecting plate to rotate 180o; the front end of the connecting plate is respectively connected to the fixed plate a and the fixed plate b, and the fixed plate a It is fixedly connected with the fixed plate b through four support columns; the fixed plate a is connected with the product guiding mechanism I and the semi-finished product clamping mechanism II, and the semi-finished product clamping mechanism clamps the semi-finished product; the fixed plate b The fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com