Method for processing pacifier

A technology of pacifier and processing method, applied in the direction of coating, etc., can solve the problems of affecting safety, unstable performance, extrusion deformation of pacifier, etc., to achieve the effect of convenient operation, increasing structural diversity, and ensuring toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

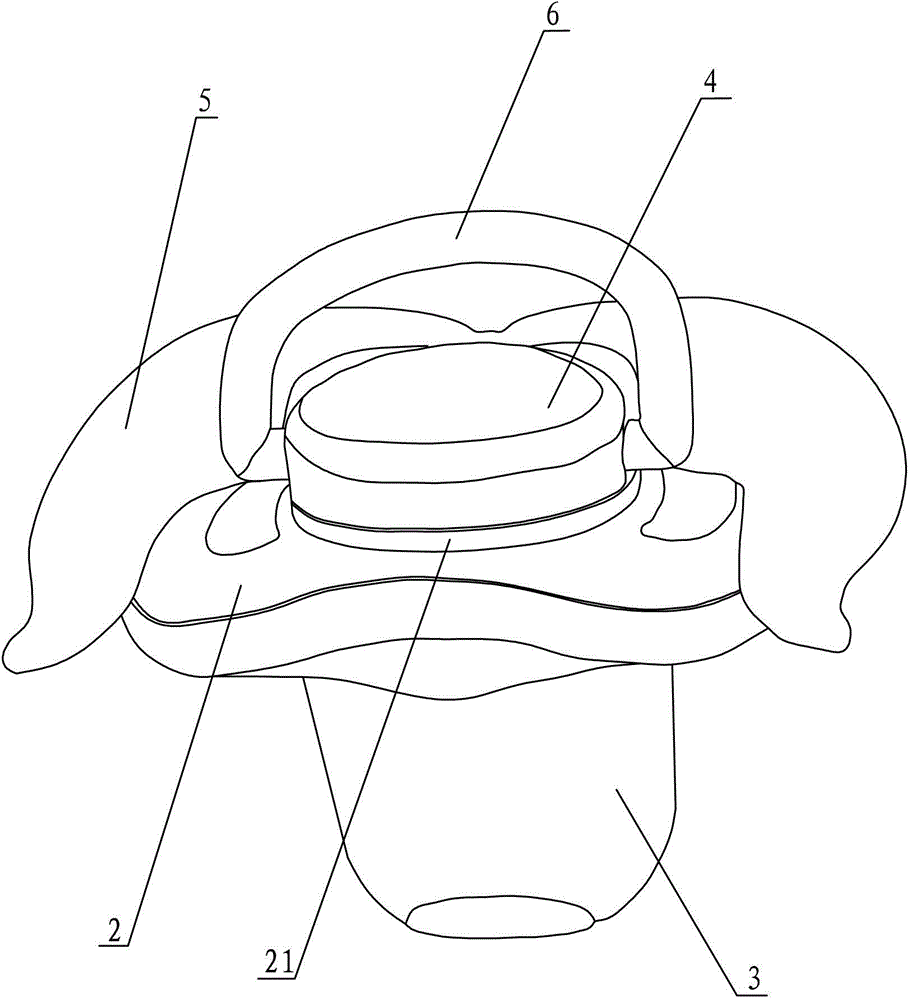

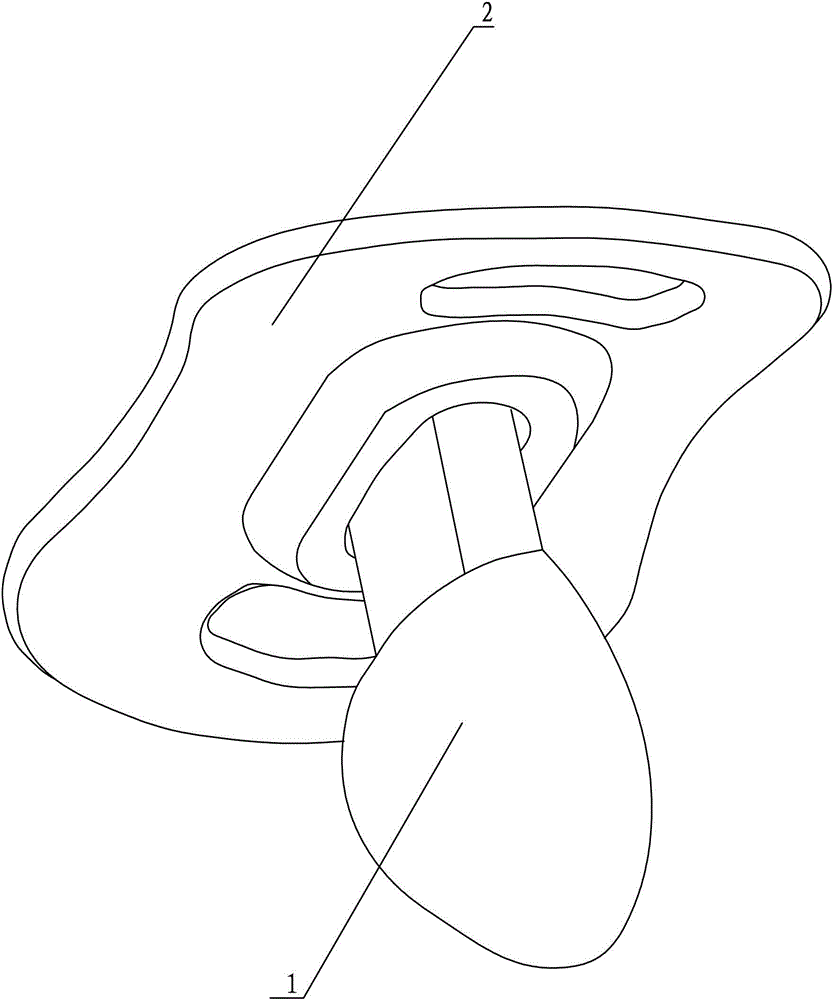

[0026] refer to figure 1 and figure 2 : the processing method of the pacifier, the pacifier comprises a pacifier head 1, a baffle plate 2 and an upper cover 4, and the pacifier processing steps are as follows:

[0027] a. Install the injection mold on the LK 130T horizontal injection molding machine to inject the nipple 1 and the baffle 2 respectively;

[0028] b. Install the injection mold on the LK 130T horizontal injection molding machine to perform secondary injection molding on the upper cover 4;

[0029] c. Cooperate and install the nipple 1 after injection molding in step a and the baffle plate 2 in step a;

[0030] d. Install the upper cover 4 in step b with the nipple 1 and the baffle 2 in step c, and the upper cover 4 and the baffle 2 seal the nipple 1;

[0031] e. The baffle plate 2 and the upper cover 4 in step d are welded by ultrasonic waves.

[0032] The raw material used for the nipple 1 is silica gel, the base material for the secondary injection mol...

Embodiment 2

[0043] The processing method of the pacifier is the same as that of Example 1, the only difference being that when the baffle plate 2 and decorative part 5 in step d are ultrasonically welded to the upper cover 4 in step e, the delay time of the ultrasonic welding process is 1s, and the welding time is 1s. The time is 1, the curing time is 1.4s, and the working pressure is 5KPA.

Embodiment 3

[0045] The processing method of the pacifier is the same as that of Example 1, the only difference is that when the baffle 2 and the upper cover 4 in step d, the decorative part 5 and the upper cover 4 in step e are ultrasonically welded, the delay time of the ultrasonic welding process is adopted The welding time is 1.4s, the welding time is 0.8s, the curing time is 1.3s, and the working pressure is 10KPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com