Step door pocket capable of cut and free of upper and lower grooves

A technology of steps and door pockets, applied in the direction of window/door frames, etc., can solve problems such as waste of electricity, damage in transportation, and labor cost, and achieve the effects of saving machine costs, increasing production, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

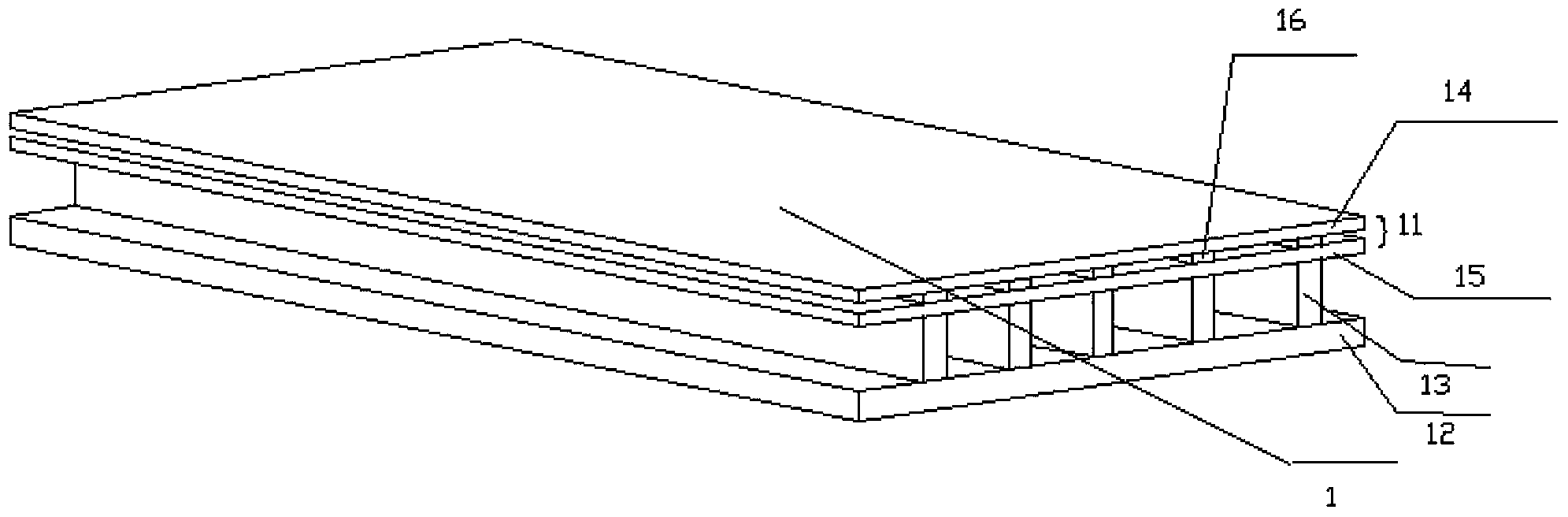

[0045] The first preferred embodiment of the present invention includes: a cover plate 1, a step member, lines and rubber strips.

[0046] The structure of cover plate 1 described in the present embodiment is:

[0047] The cover plate 1 includes a surface layer 11, a bottom layer 12 and several first connecting ribs 13, and the surface layer 11 and the bottom layer 12 are connected through several first connecting ribs 13, thereby forming a Several stepped slots. The surface layer 11 includes an upper layer 14 , a lower layer 15 and a plurality of second connecting ribs 16 , the upper layer 14 and the lower layer 15 are connected through a plurality of second connecting ribs 16 , thereby forming a glue strip slot on the surface layer 11 . The inner surface of the surface layer 11 of the cover plate 1 is parallel to the inner surface of the bottom layer 12 . The door cover structure automatically generates the rubber strip slot and the step slot, and does not need to use a sp...

Embodiment 2

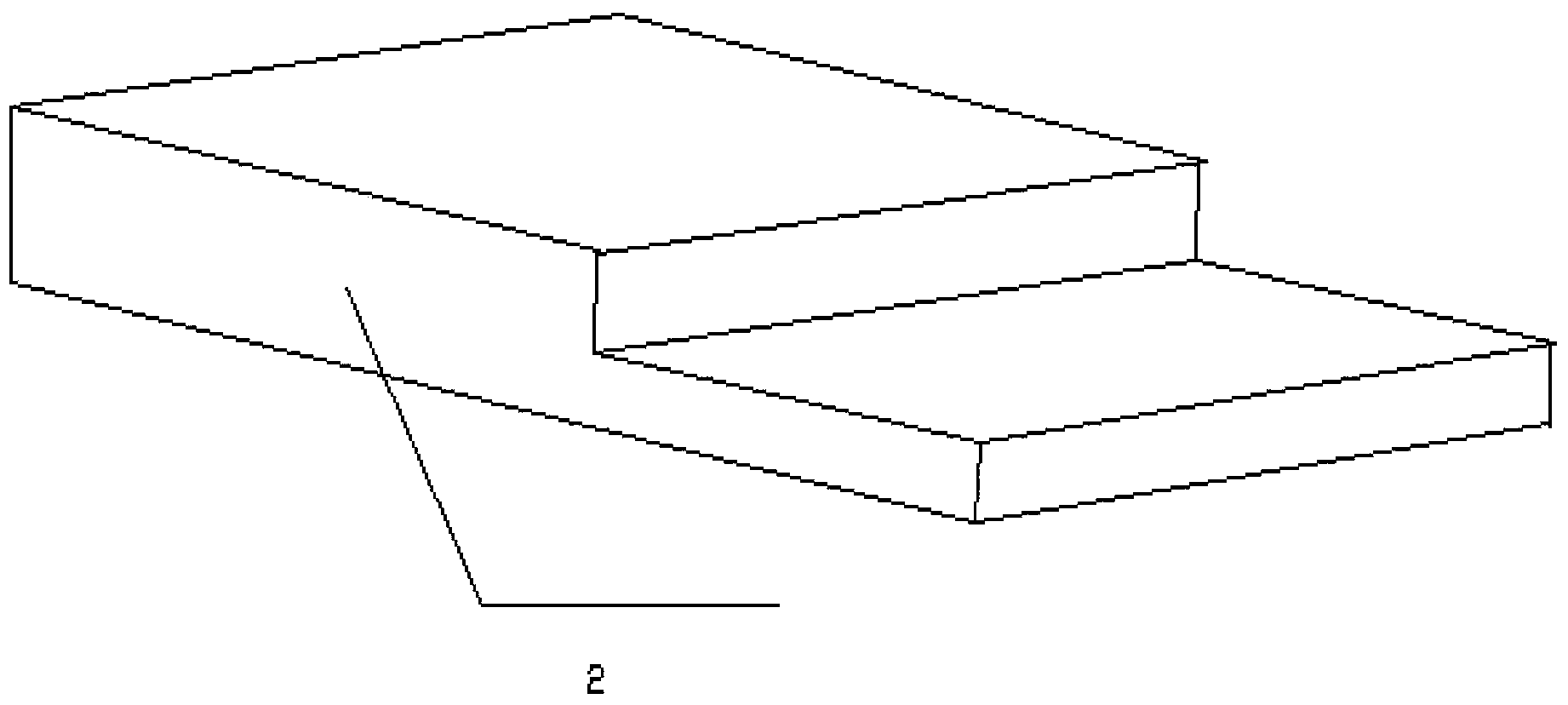

[0067] The second preferred embodiment of the present invention includes cover boards, rubber strips, step components and lines.

[0068] Please refer to Figure 12, the cover plate includes a surface layer 115, a bottom layer 111 and a first connecting rib 116, and the surface layer 115 and the bottom layer 111 are connected by several first connecting ribs 116, thereby forming several Step slots, the surface layer 115 includes an upper layer 110, a lower layer 114 and some second connecting ribs 113, the upper layer 110 and the lower layer 114 are connected by several second connecting ribs 113, thereby forming a glue strip on the surface layer 115 Slot 112. The inner surface of the surface layer 115 of the cover plate 1 is parallel to the inner surface of the bottom layer 111 .

[0069] In this embodiment, the rubber strip slot 112 of the cover board extends along a direction perpendicular to the length direction of the cover board (that is, the rubber strip slot 112 exte...

Embodiment 3

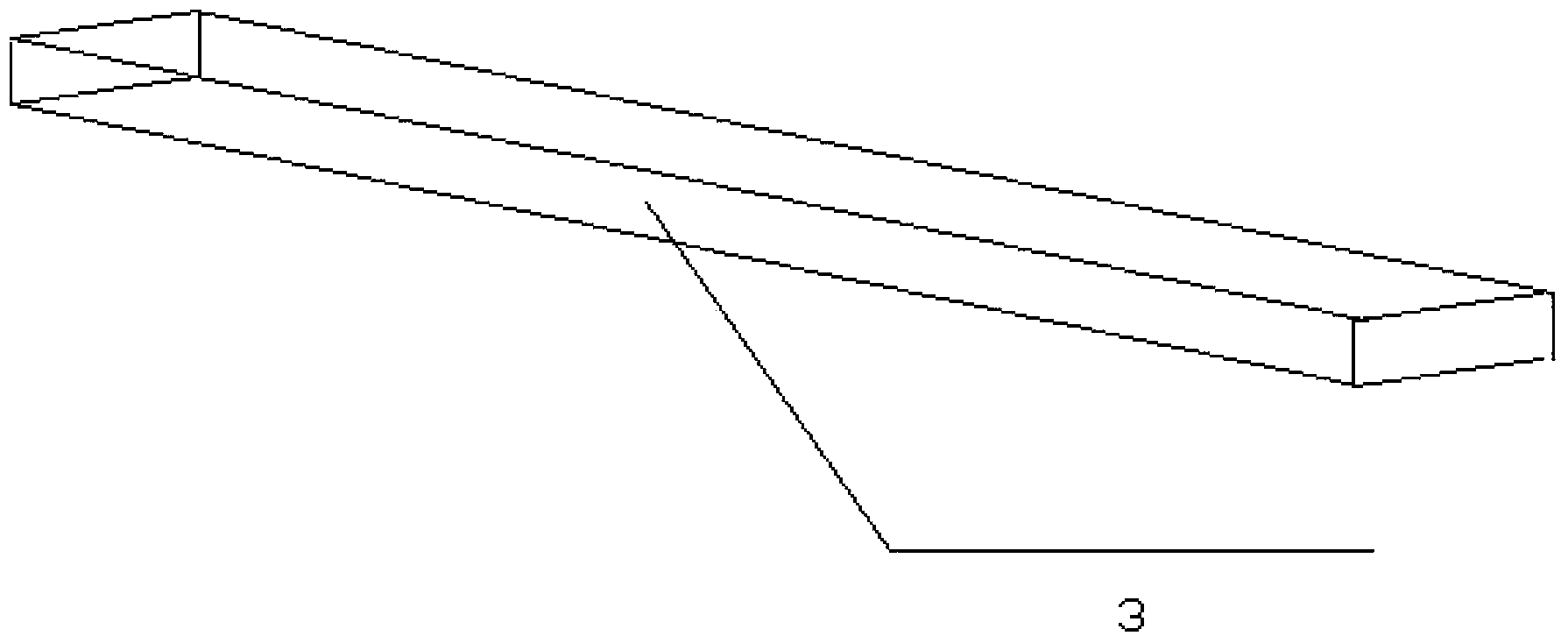

[0072] The step door cover that can be cut without opening the upper and lower grooves in the third preferred embodiment of the present invention is different from the step door cover that can be cut without opening the upper and lower grooves in the first preferred embodiment and the second preferred embodiment only in the cover plate The first connecting rib and the second connecting rib included in the structure are different, and the rest of the structure is the same as that of the first preferred embodiment and the second preferred embodiment of the present invention. Therefore, starting from simplicity, here we will mainly describe the parts that are different from the first embodiment and the second embodiment, that is, focus on explaining the structure of the first connecting rib and the second connecting rib of the step door cover plate that can be cut without opening the upper and lower grooves. .

[0073] The connecting ribs hereinafter all include the first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com