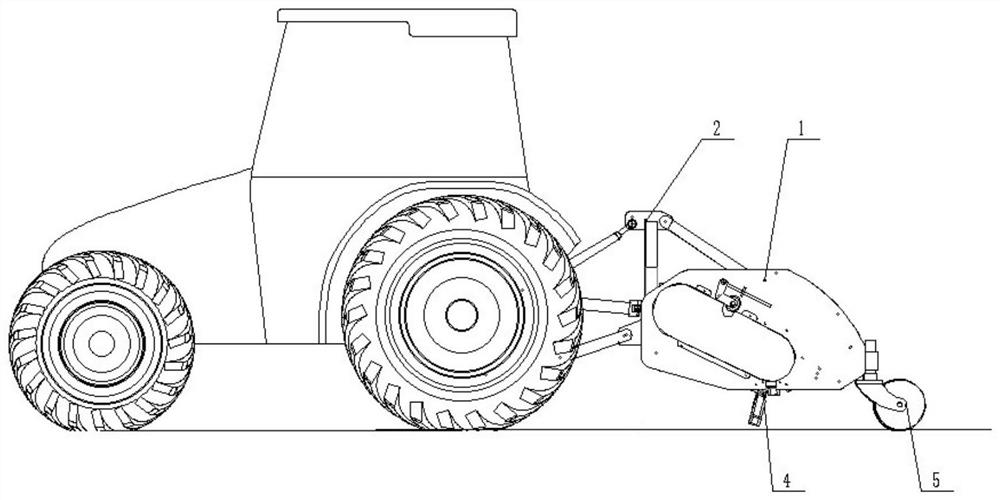

Variable-shaft-diameter ridge-imitating cassava stem smashing and returning machine

A cassava rod and shaft diameter technology, which is applied in the field of a ridge-shaped cassava rod crushing and returning machine with variable shaft diameter, can solve the problems of polluting the environment, large load, complex structure of the whole machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

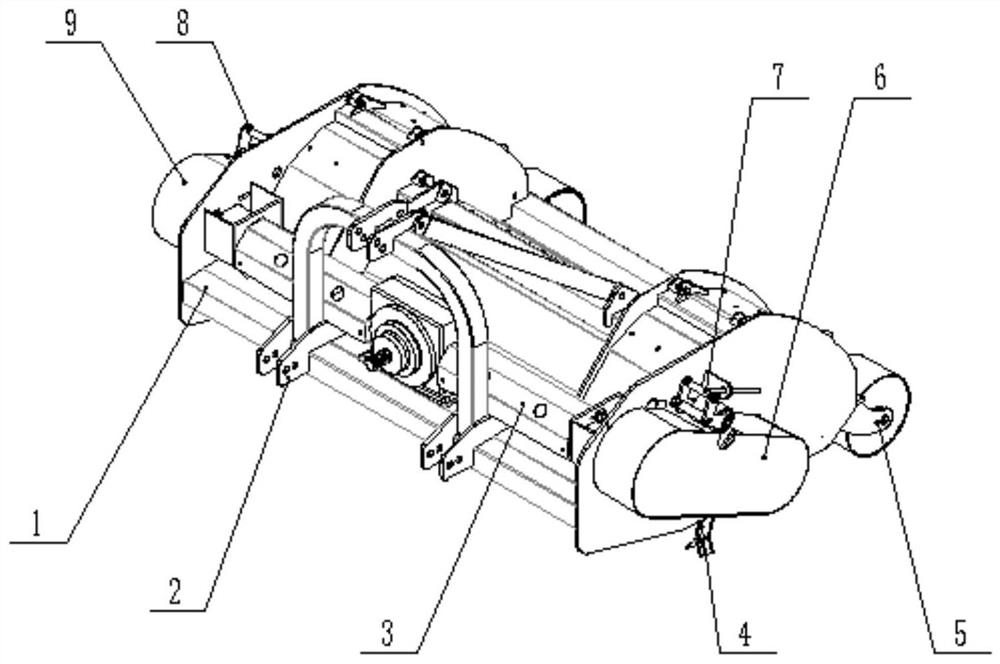

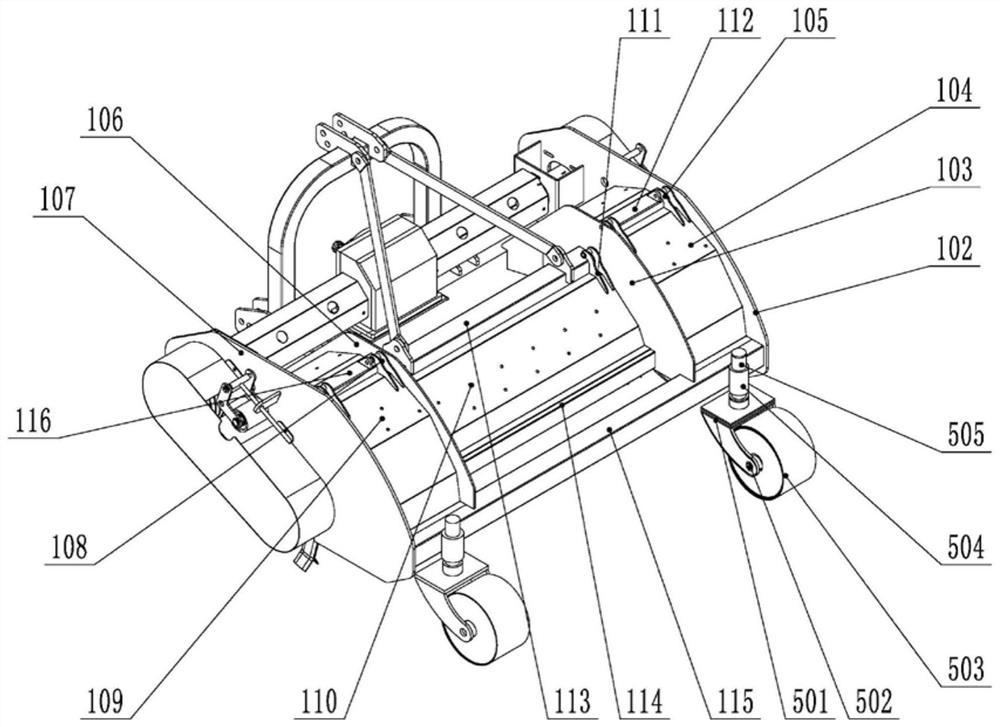

[0037] In order to make the object, technical solution and advantages of the present invention clearer and clearer, the following references are made to the appended Figure 1-7 The present invention is further described in detail by giving examples.

[0038] The existing cassava stalk crushing and returning technology and equipment research has achieved preliminary results. In order to realize the perfect combination of agricultural machinery and agronomy, the problem of incomplete crushing of ridge residues for cassava wide and narrow double-row ridge planting mode needs to be solved urgently. Therefore, with the goal of high efficiency, low loss, low consumption and practicality, the present invention focuses on designing the structure of the horizontal cassava stalk grinder and the arrangement of the blades, optimizing the cassava stalk crushing mechanism, and demonstrating, improving, perfecting and finalizing the design through field tests. , to achieve the practicality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com