Door and window sleeve capable of cut and closed up

A technology of door and window covers and closing strips, which is applied in the field of door and window covers, can solve the problems of inability to cut and adjust, cannot be re-engaged, and cannot be mass-produced, so as to achieve the effect of saving machine costs and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

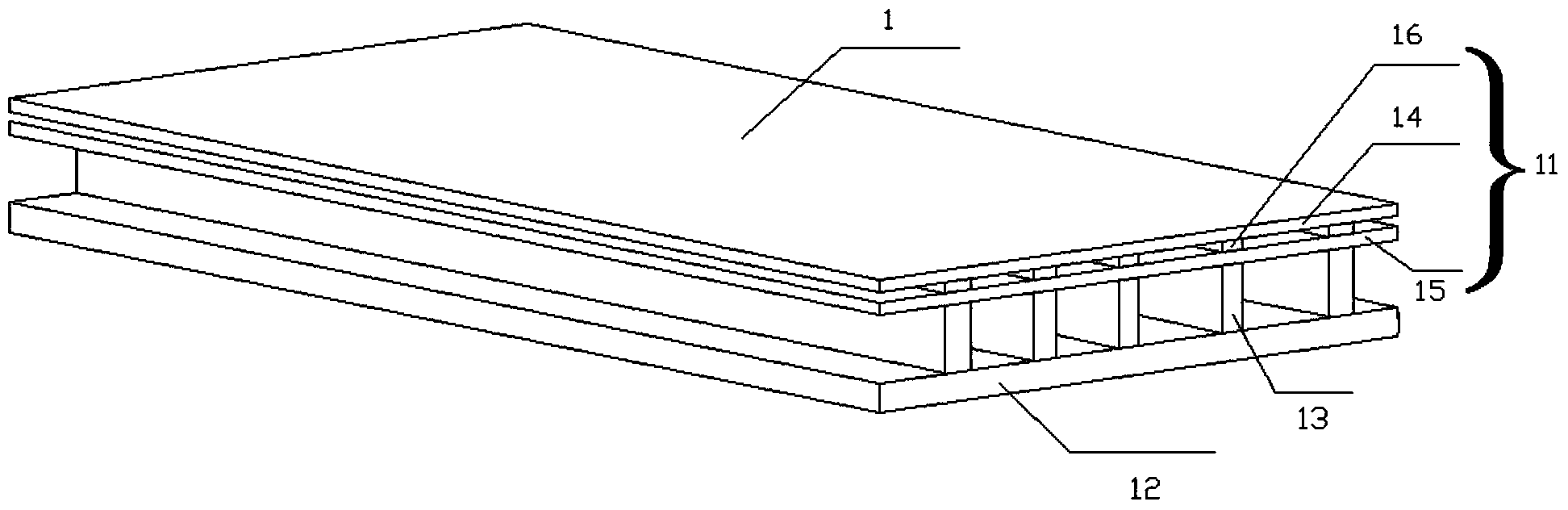

[0064] The first preferred embodiment of the present invention includes: a cover plate 1, a step member and a line.

[0065] The structure of the cover plate 1 in this embodiment is:

[0066] The cover plate 1 includes a surface layer 11, a bottom layer 12 and a number of first connecting ribs 13. The surface layer 11 and the bottom layer 12 are parallel to each other and are connected by a number of first connecting ribs 13 perpendicular to the surface layer 11, thereby Between the surface layer 11 and the bottom layer 12 is formed a line slot that intermittently penetrates the entire cover plate 1. The surface layer 11 includes an upper layer 14, a lower layer 15 and a number of second connecting ribs 16. In this embodiment, the upper layer 14 and the lower layer 15 are parallel to each other, and the upper layer 14 and the lower layer 15 are connected by a plurality of second connecting ribs 16 perpendicular to the upper layer 14, thereby forming a discontinuity on the surface ...

Embodiment 2

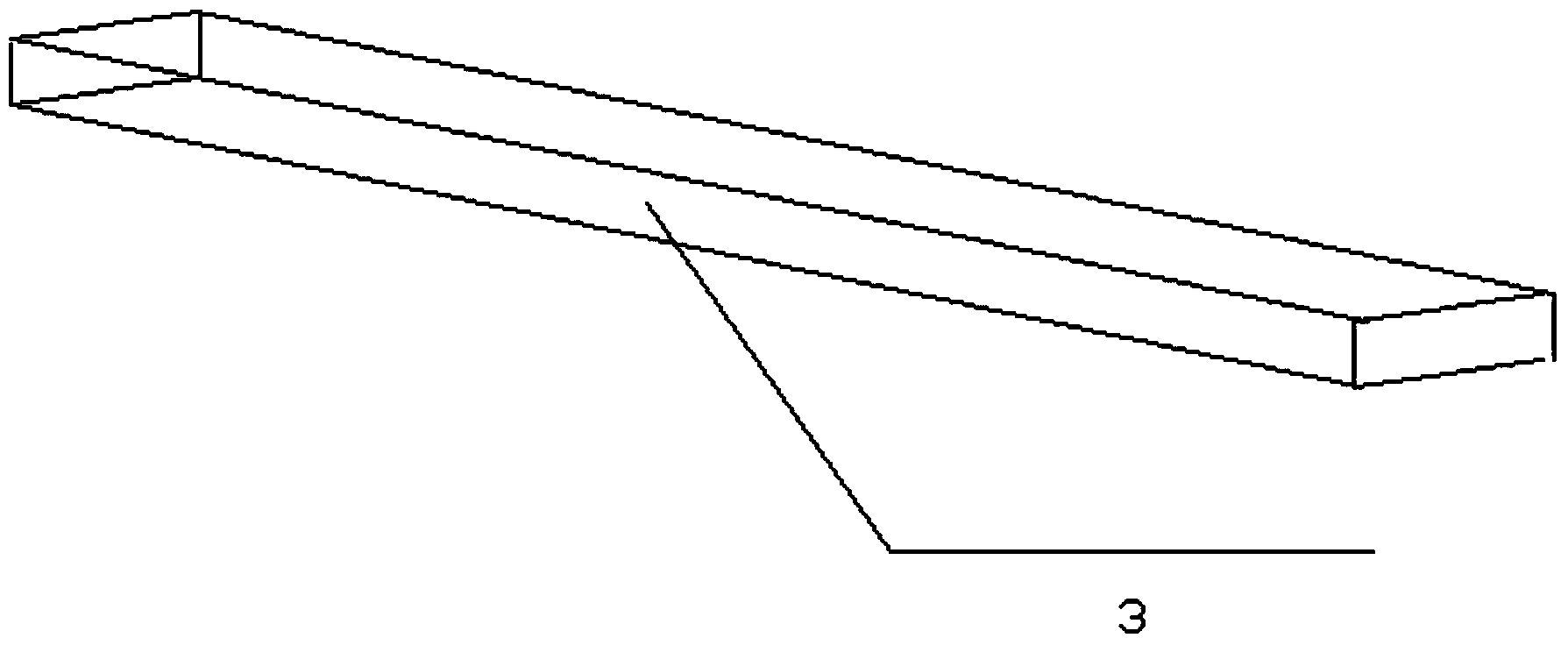

[0092] The door and window cover of the second preferred embodiment of the present invention differs from the first preferred embodiment only in the way of connecting the lines and the cover plate 1. The first embodiment adopts the retreat installation method, and the present embodiment adopts the full cover installation method. The rest of the structure is the same as the door and window cover of the first preferred embodiment of the present invention. Therefore, for the sake of simplicity, the different parts from the first embodiment are mainly described here, that is, the connection method of the line and the cover plate 1 is emphasized.

[0093] The door and window cover of the second preferred embodiment of the present invention includes: a cover plate 1, a line and a step member.

[0094] The connection method of the cover plate 1 and the step member is the same as that of the first embodiment.

[0095] Please refer to Figure 14 A preferred implementation of the line in this...

Embodiment 3

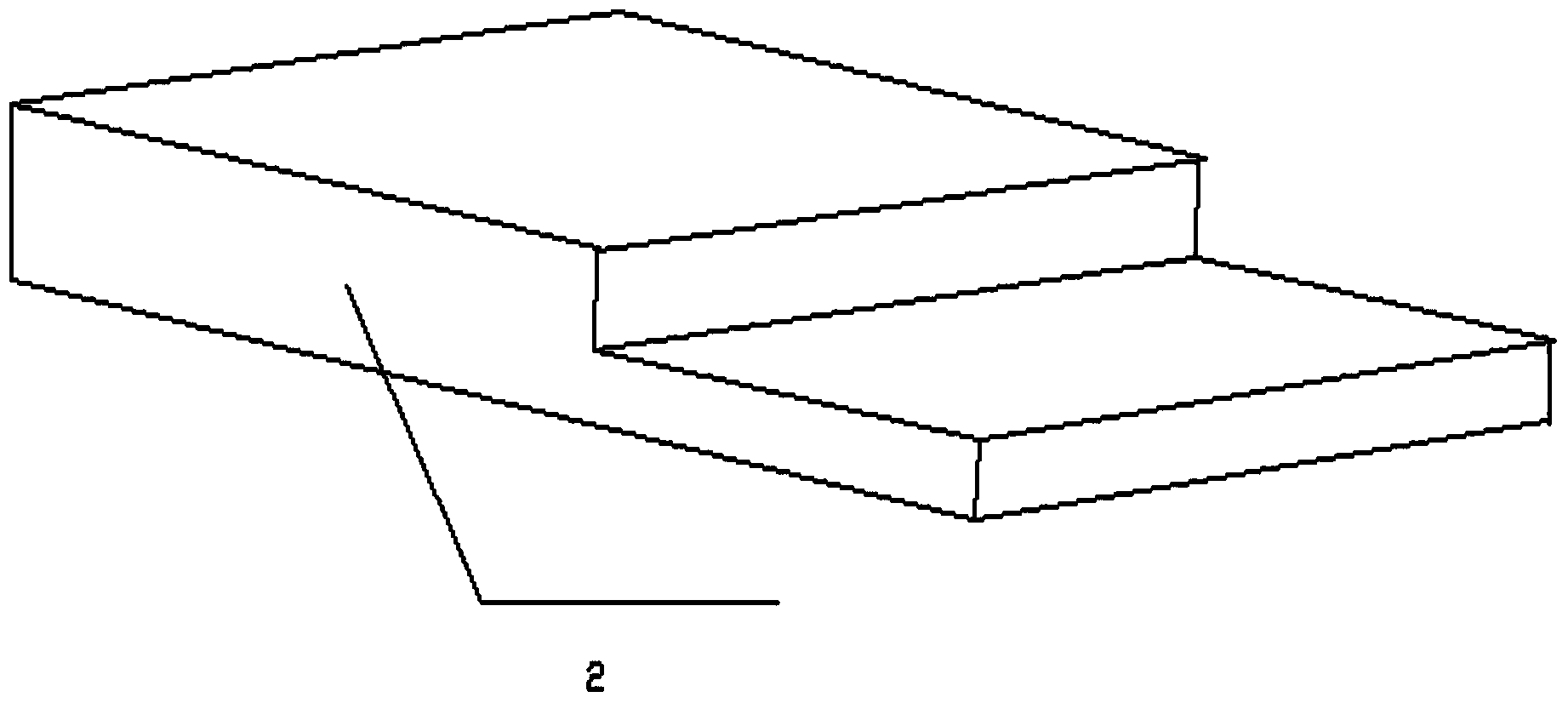

[0101] The difference between the door and window cover of the third preferred embodiment of the present invention and the door and window cover of the first and second preferred embodiments lies in the way in which the steps are formed. The rest of the structure is the same as the first preferred embodiment of the present invention. The door and window cover of the second preferred embodiment is the same. Therefore, for the sake of brevity, the differences from the first embodiment and the second preferred embodiment are mainly described here, that is, the step formation structure is emphasized.

[0102] Please refer to Figure 5 , The door and window cover of the third preferred embodiment of the present invention includes: a cover plate, a line and a closing strip.

[0103] The inner surface of the surface layer of the cover plate is parallel to the inner surface of the bottom layer, and the surface layer and the bottom layer are connected by a plurality of first connecting ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com