Filter rod transmission device and method in tobacco industry

A filter rod and conveying device technology, applied in tobacco, smoke oil filter, application, etc., can solve the problems of inability to maintain pressure, increase air consumption, increase cost, etc., achieve simplified pressure transformation, high sealing effect, and achieve sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

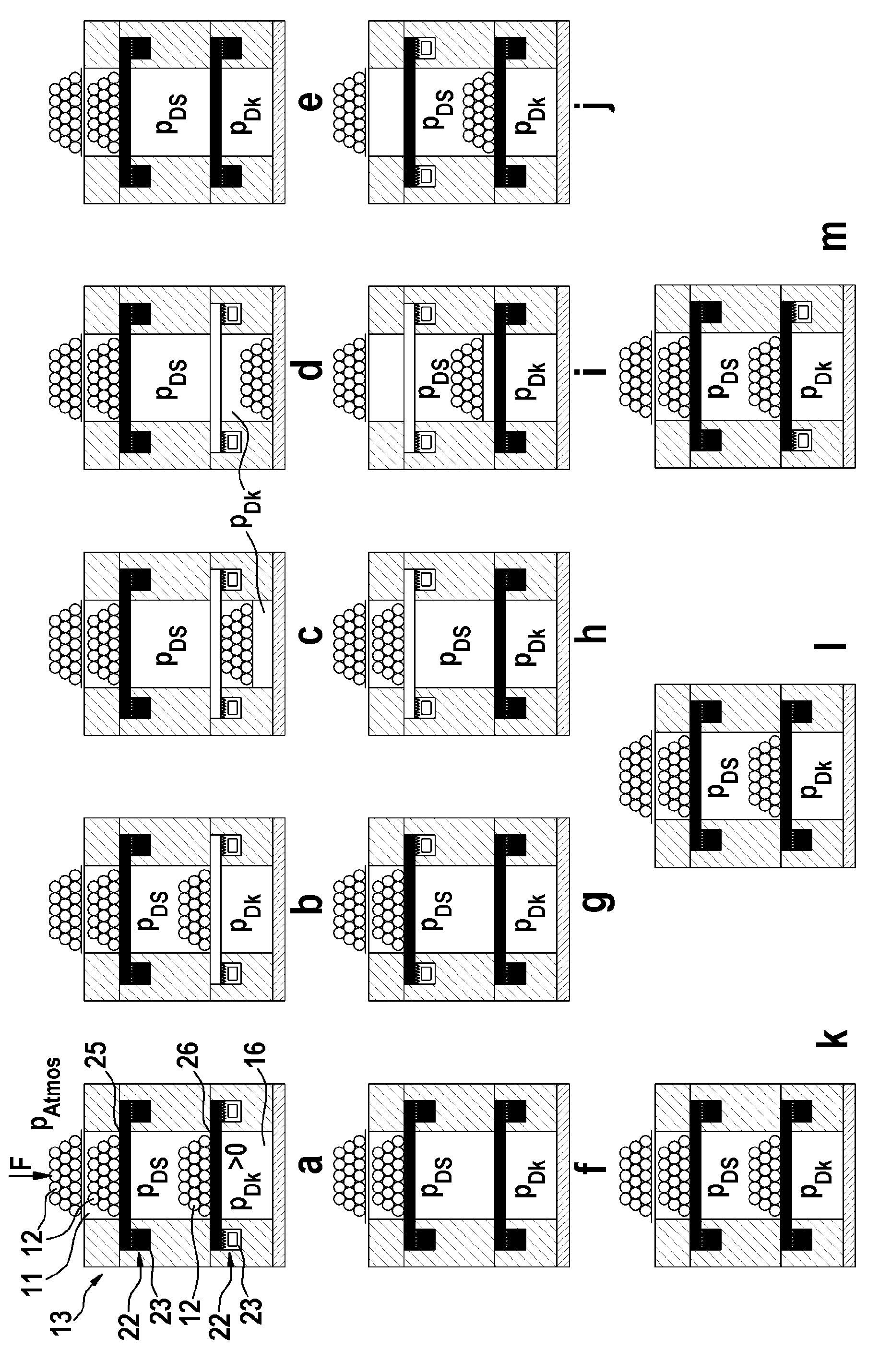

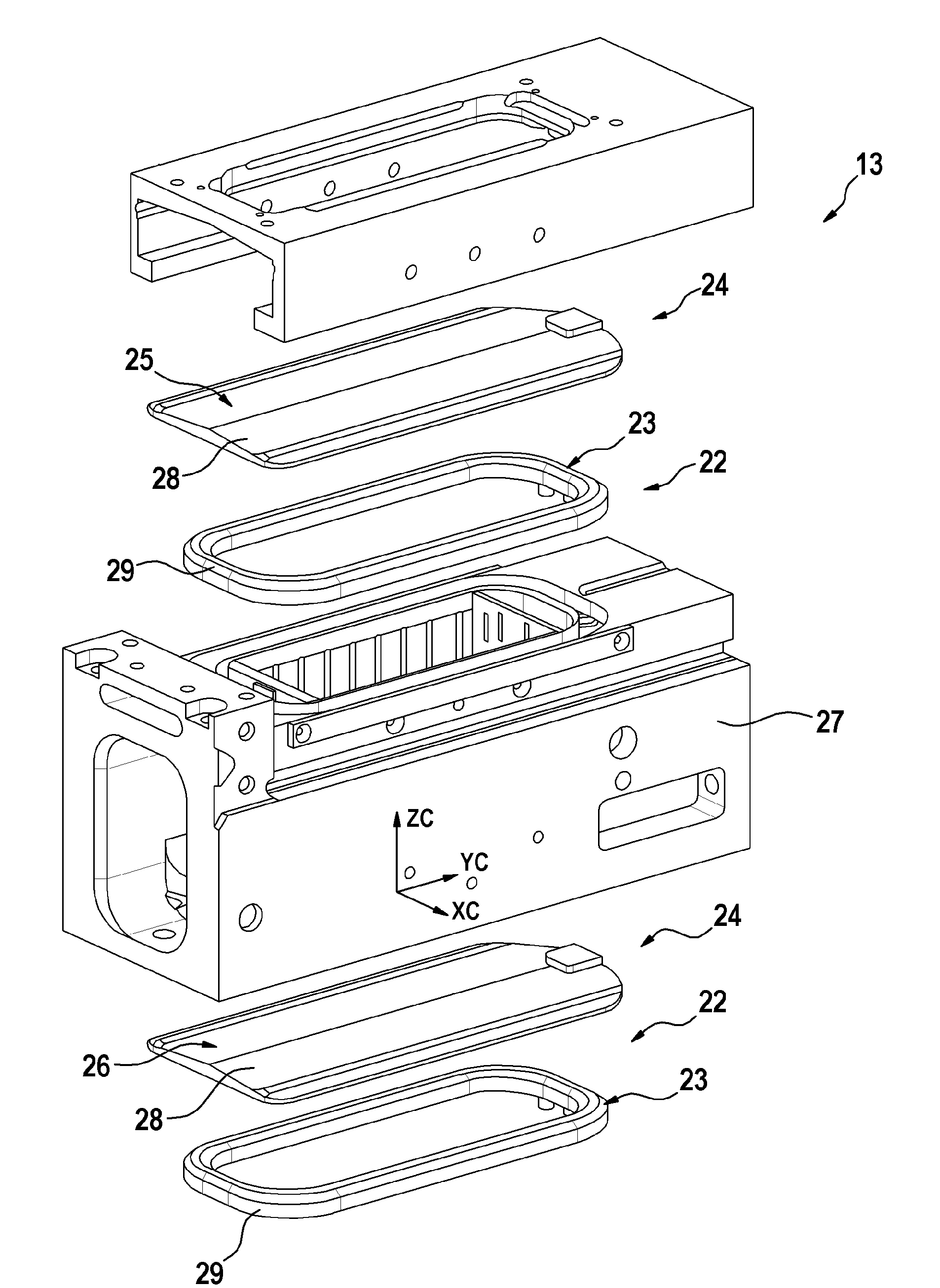

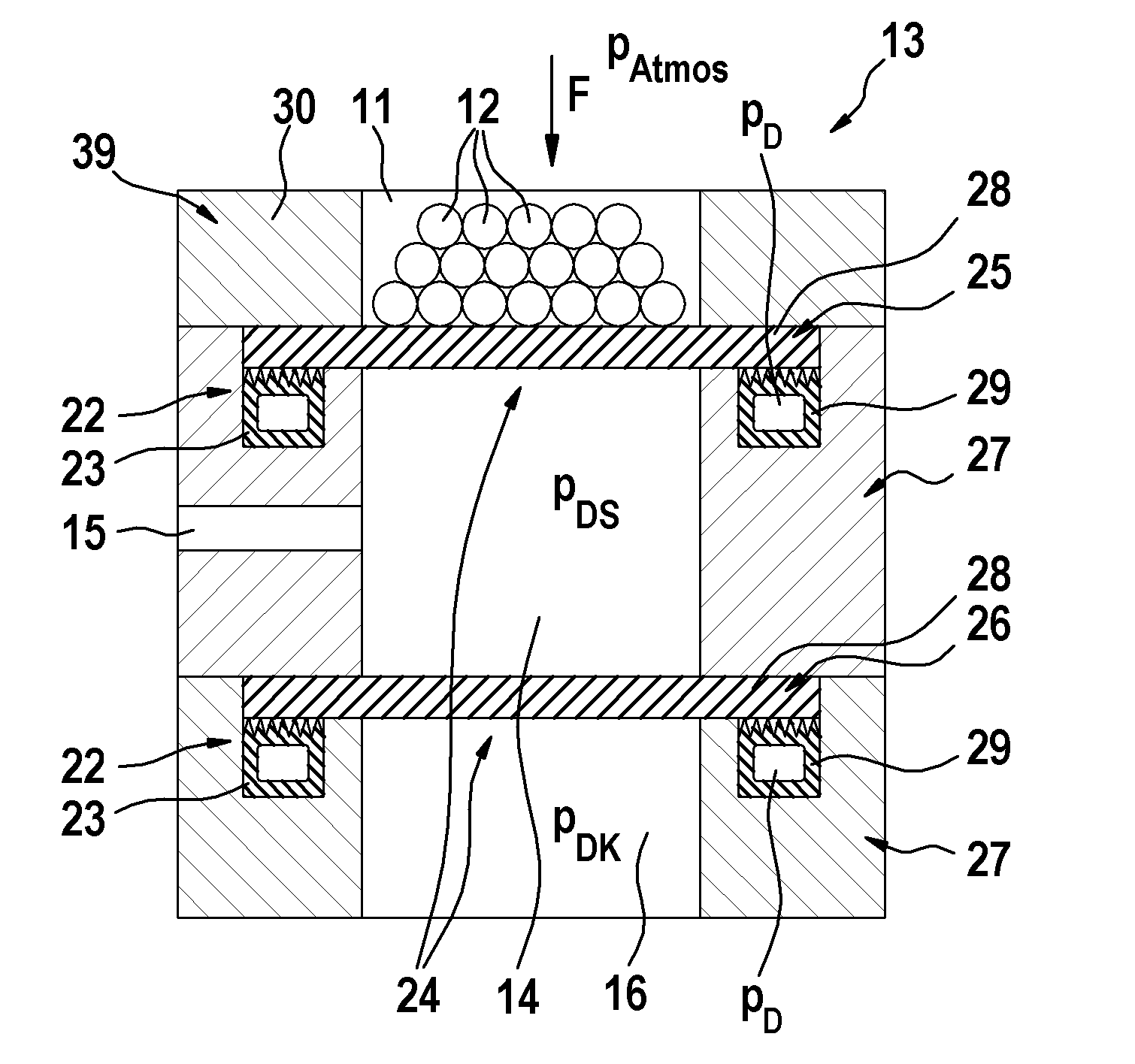

[0029] exist figure 1 The filter rod transfer device 10 is shown very schematically in . The filter rod transfer device 10 comprises a compartment 11 for receiving and storing filter rods 12 . In the tank 11 there is ambient or atmospheric pressure p Atmos . Starting from the magazine 11 , the filter rod transfer device 10 also includes a pressure lock chamber 13 for receiving and temporarily storing the filter rods 12 along the conveying direction F of the filter rods 12 . The pressure lock chamber 13 has a lock chamber chamber 14 with a pressure p for utilizing the pressure inside the lock chamber 14 DS A channel 15 that establishes and relieves pressure levels that are offset relative to the environment. The pressure lock chamber 13 can pass through the lock chamber part 24 with respect to having atmospheric pressure p Atmos environment is blocked. The filter rod transfer device 10 also has a pressure chamber 16 in which, during operation of the filter rod transfer de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com