Lubricating grease injection tool for bearing

A technology of injecting grease and tooling, which is applied in the field of tooling, can solve problems that affect the performance of bearings and cannot ensure that the bearings are completely lubricated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described below with reference to the accompanying drawings.

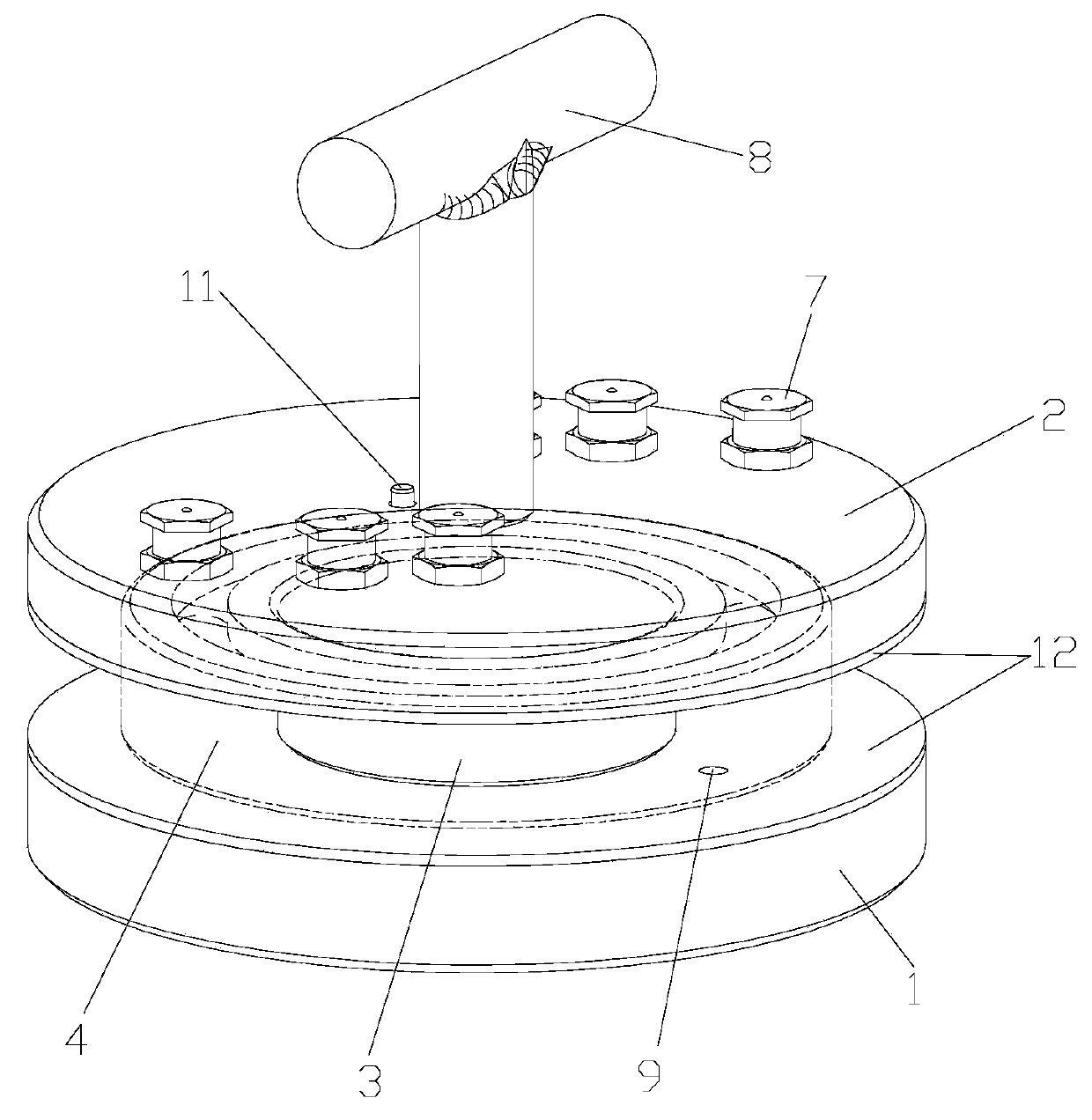

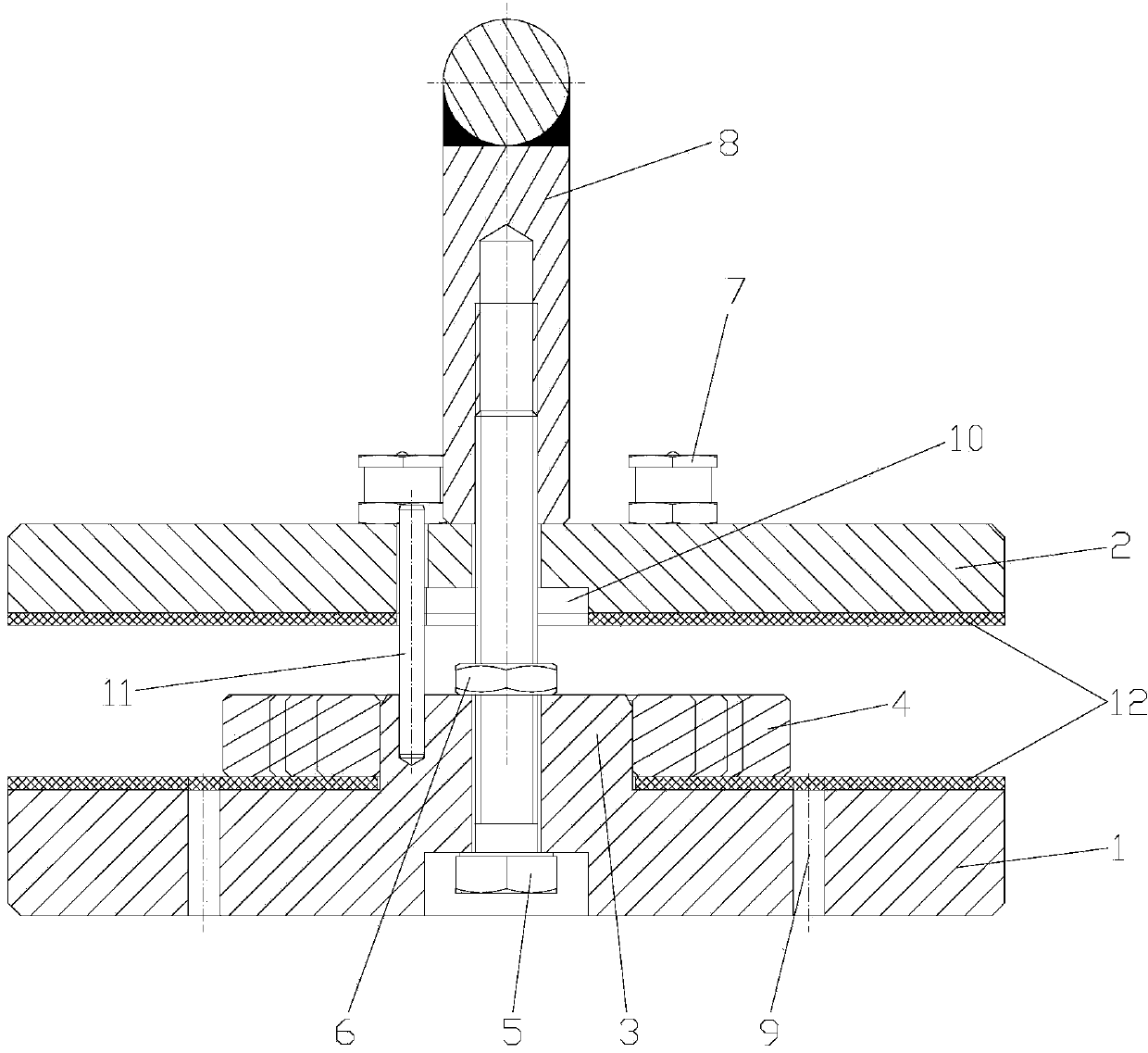

[0015] as attached figure 1 , 2 A bearing grease injection tool according to the present invention as shown includes a base plate 1, a pressure plate 2, a boss 3, a guide ring 4, a screw 5, a nut 6, a grease nipple fixing 7, a grease nipple (not shown in the figure) and The handle 8; the bottom plate 1 is provided with a plurality of oil leakage holes 9; the pressure plate 2 is arranged above the bottom plate 1; the bottom plate 1 is provided with a boss 3; the guide ring 4 is sleeved outside the boss 3, Close to the bottom plate 1; the bottom center of the bottom plate 1 is provided with a screw 5 vertically upward; the screw 5 passes through the boss 3 and the pressure plate 2; the screw 5 is provided with a nut 6; the nut 6 is located on the boss 3 and the pressure plate 2; the bottom of the pressure plate 2 is provided with a groove 10 that can accommodate the nut 6; the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap