Composite multipurpose detachable thermal insulation block and manufacturing method thereof

A production method and technology of insulation blocks, which are applied in the direction of heat preservation, pipeline protection, and pipeline protection through heat insulation, can solve the problems of disjointed fibers, affecting energy saving and emission reduction, etc., and achieve good strength, low cost, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

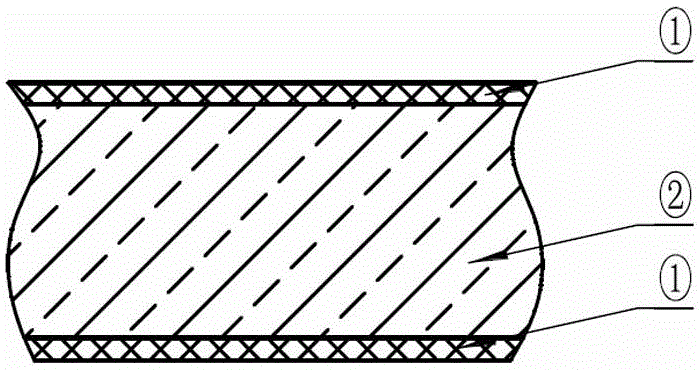

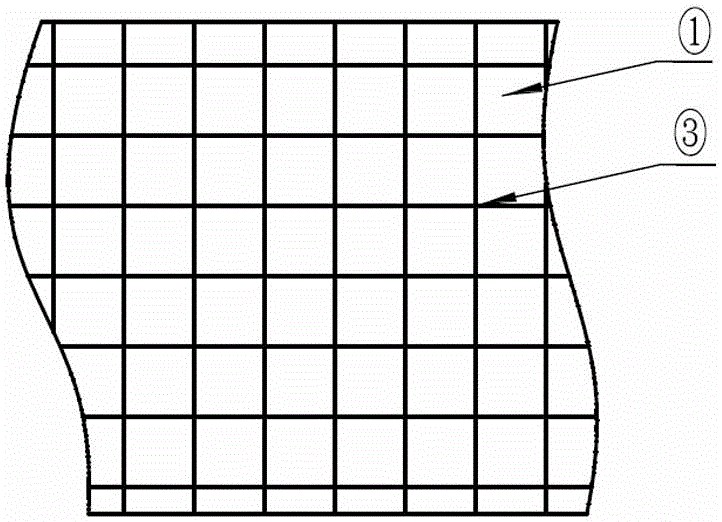

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: figure 1 , 2 As shown in the figure, the composite multi-purpose detachable thermal insulation material of the present invention is mainly composed of a middle thermal insulation substrate 2 and an alkali-free glass fiber cloth 1 laid up and down. The thermal insulation substrate 2 is made of conventional The ratio of alkali-free glass fiber and aluminum silicate wool raw materials is mixed and formed, that is, the thermal insulation substrate 2 is the conventional alkali-free glass fiber needle-punched felt raw material ratio, and is added to the formed mixed material by acupuncture processing technology. There are 20-30% of the total amount of mixed materials of alkali-free glass short fibers and 5-10% of the total amount of mixed materials of high temperature resistant glue and form a block or long, mixed and interconnected thermal insulation substrate 2 .

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com