Method for producing improved ZVT PWM converter auxiliary drives

An auxiliary drive and converter technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of the main switch tube drive phase difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

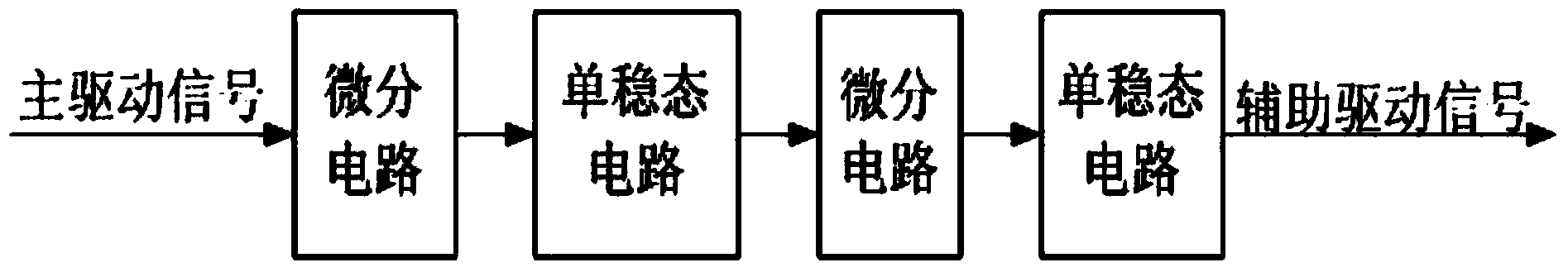

[0009] The specific implementation steps of the application method of the monostable circuit of the present invention in the converter auxiliary drive generation circuit can be found in figure 1 :

[0010] ① Through the first monostable circuit, a pulse signal with adjustable pulse width is obtained by using the falling edge of the differentiated signal of the main drive;

[0011] ② Through the second monostable circuit, the auxiliary drive is obtained by using the falling edge of the differentiated pulse signal;

[0012] ③ Adjust the phase and pulse width of the auxiliary drive to meet the working requirements of the converter;

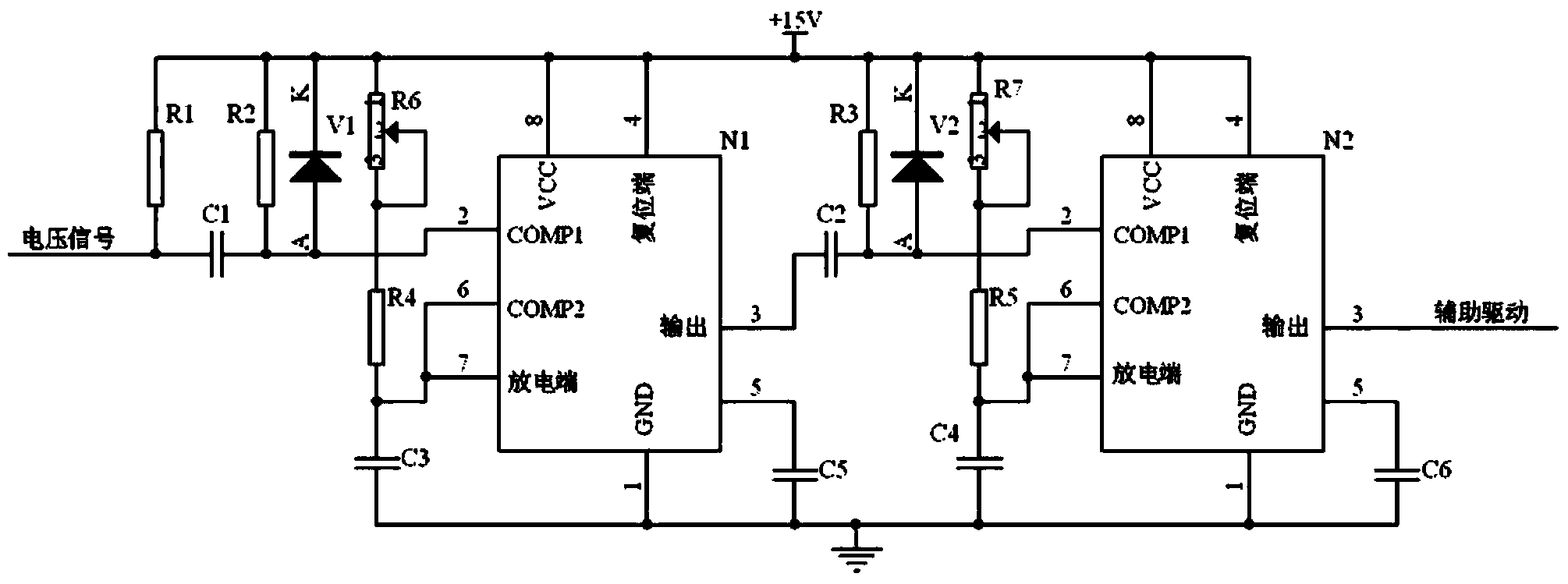

[0013] The application method of the monostable circuit of the present invention in the auxiliary drive generation circuit of the converter is shown in the schematic diagram of the circuit figure 2 , N1 and N2 in the figure are 555 timers.

[0014] ① After the main drive signal passes through the differential circuit C1 and R2, it is introduced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com