Automatic conveying device of dispensing machine

An automatic feeding and dispensing machine technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of station deviation and inconsistent feeding quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

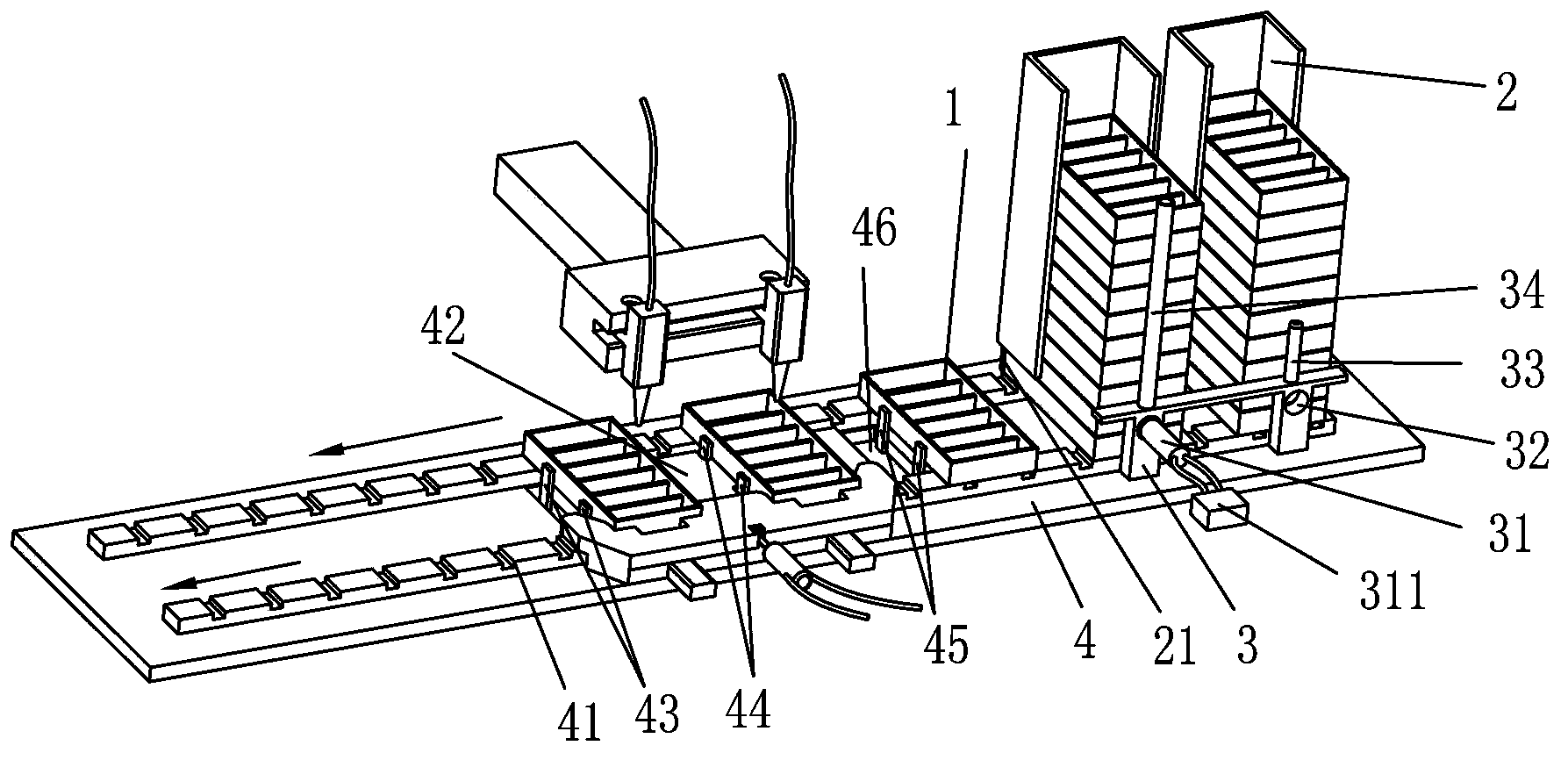

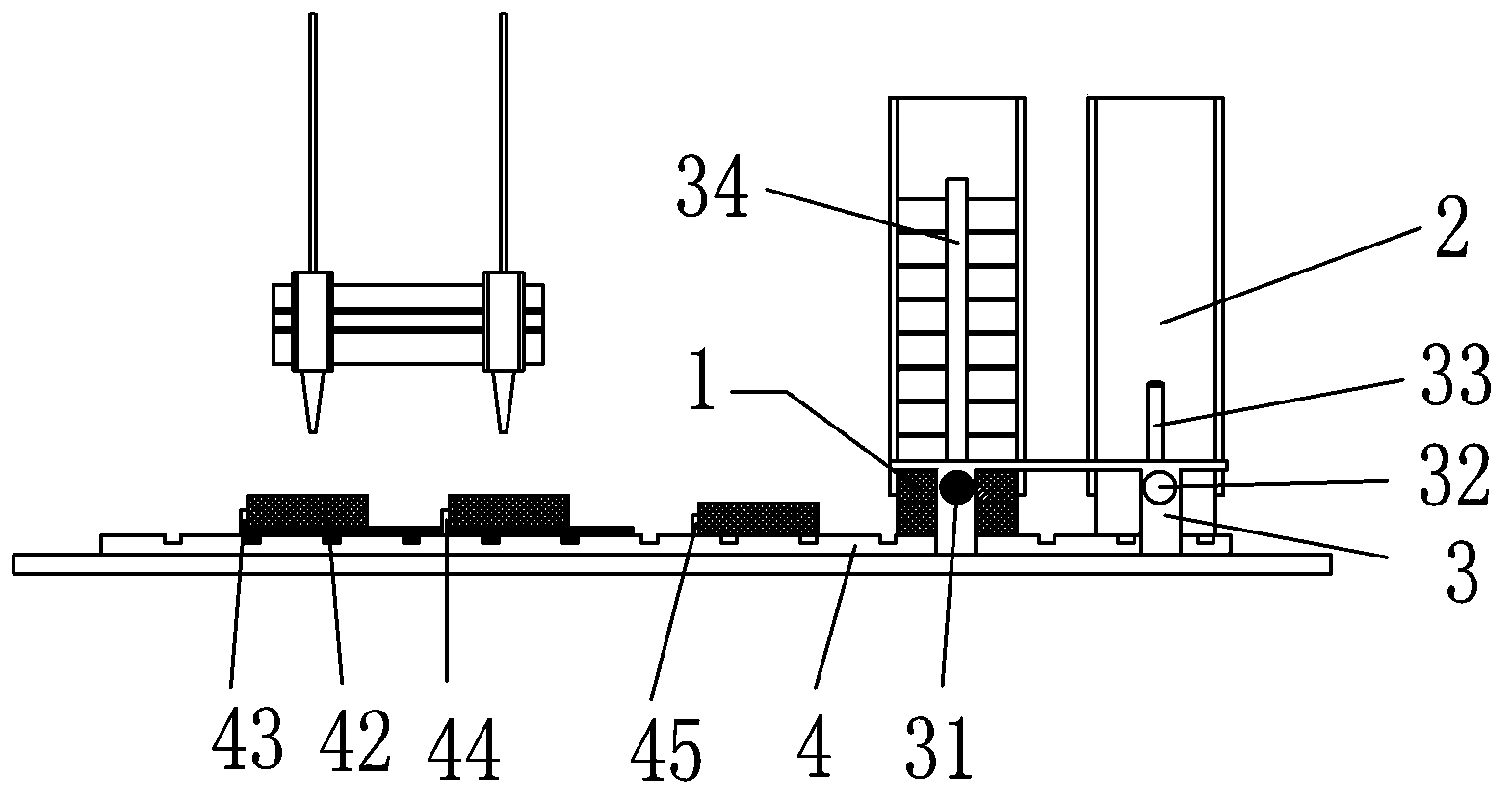

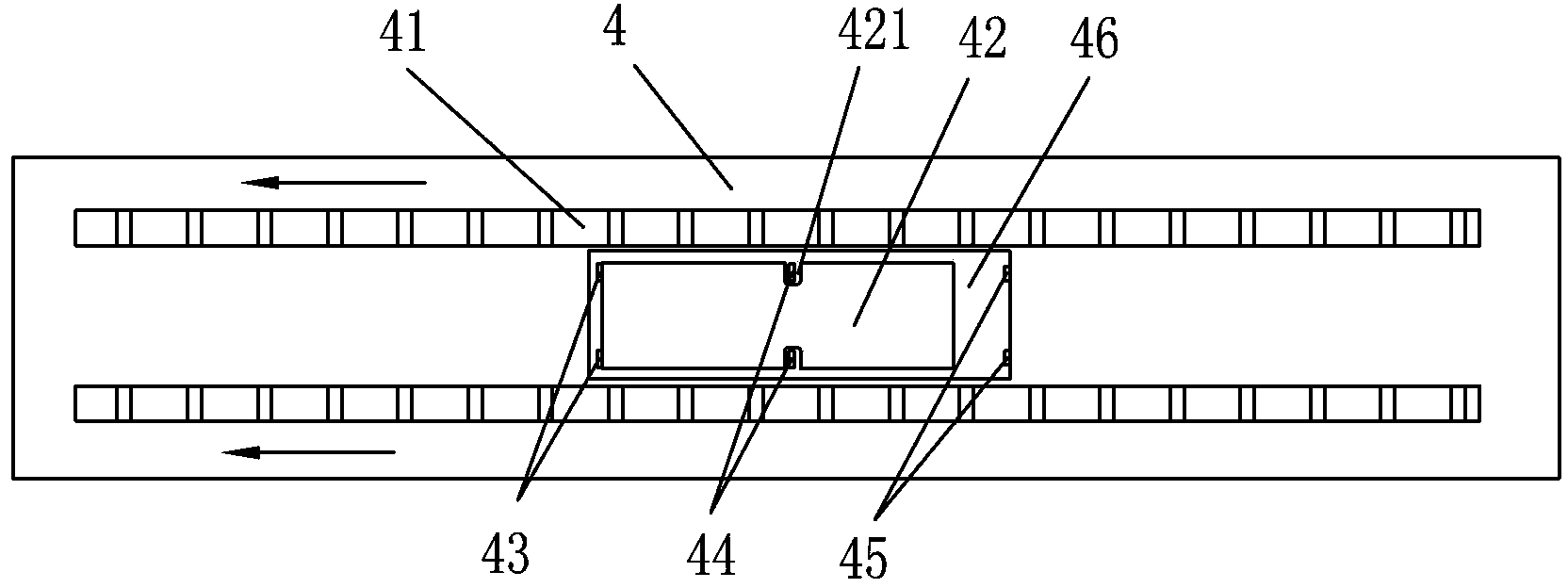

[0019] Such as Figure 1 to Figure 4 As shown, the feed point of the dispenser is located on the far right side of the dispenser. In order to improve work efficiency, the feed point is equipped with two storage boxes. The section of the storage frame 2 is half a rectangle, which is semi-open. The rectangular inner wall just matches the outline of the battery cover 1. The battery cover 1 is stacked in the storage frame 2 from top to bottom. The bottom of the storage frame 2 is not sealed. The material stopper 21, the rear material stopper 21 is a plate-shaped plane, and the inner wall is against the rear side of the battery cover 1, the front side of the battery cover 1 is provided with a front stopper 3, and the front stopper 3 is provided with a cylinder Hole 32, the center of the cylinder hole 32 falls on the side of the second last battery cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com