Chain for suspending

A technology of chains and chain plates, which is applied in the field of hanging chains, and can solve the problems of insufficient tensile strength of the hanging chains 700

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

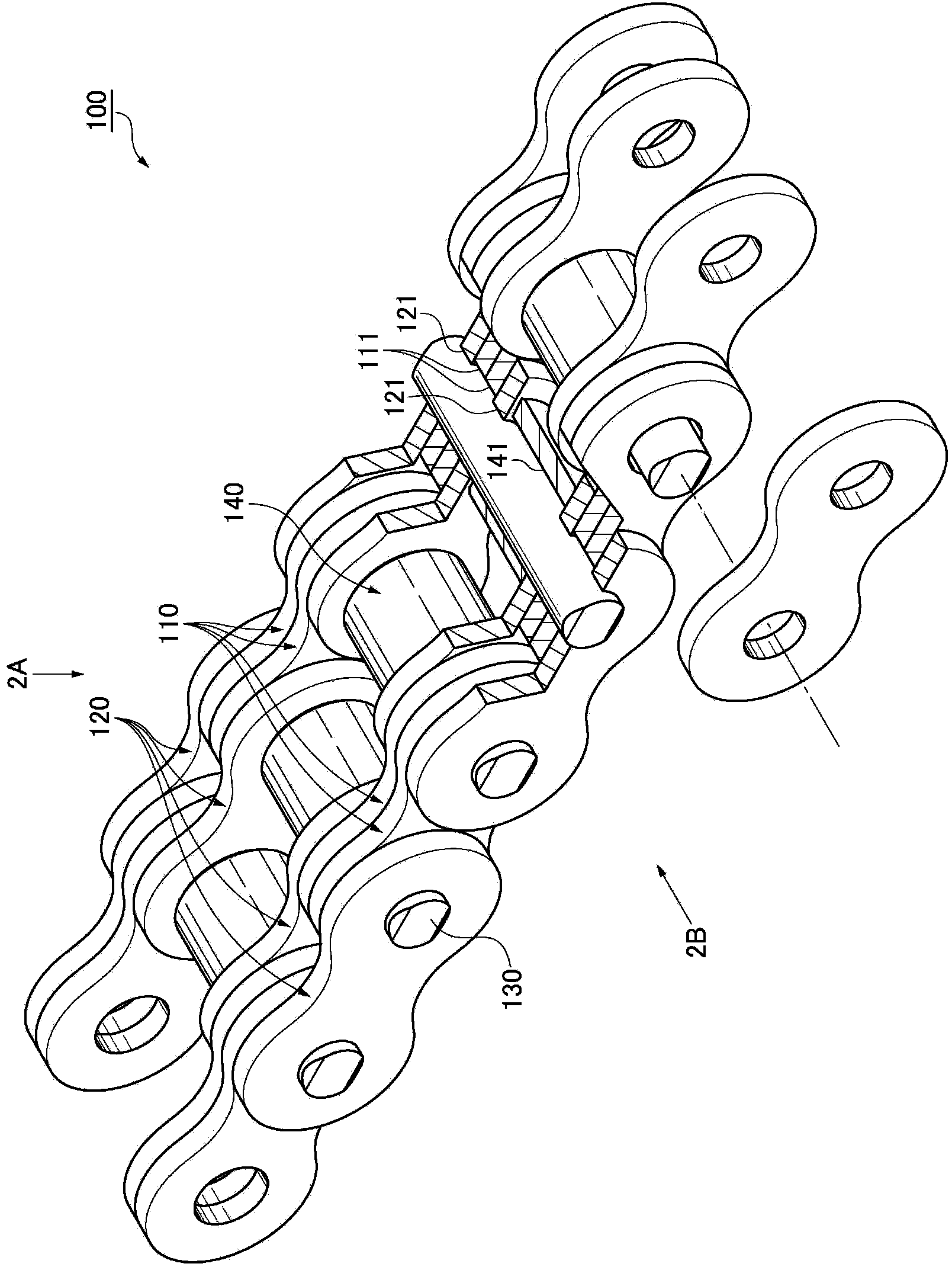

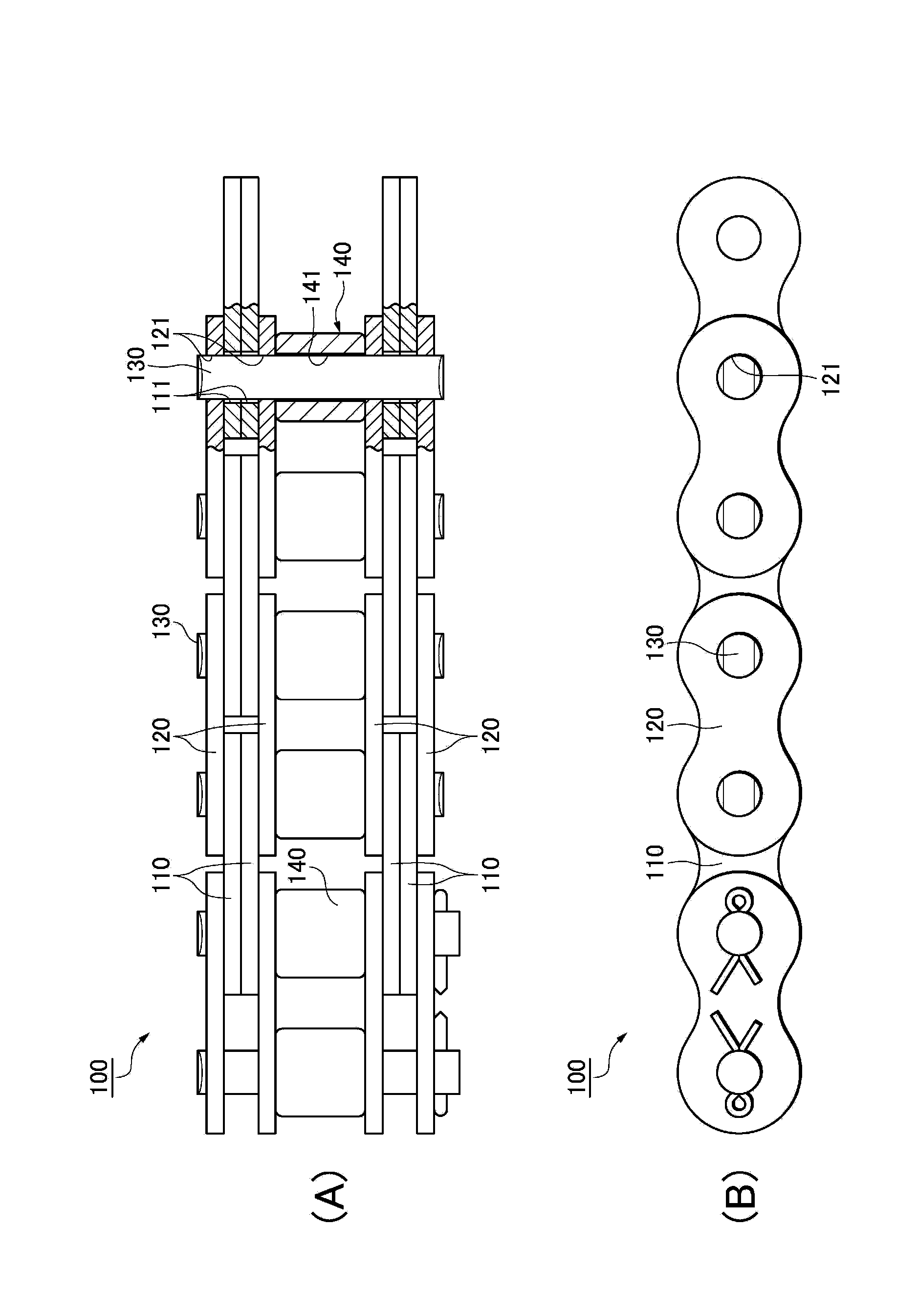

[0051] Refer below Figure 1 to Figure 5 The suspension chain 100 according to the first embodiment of the present invention will be described.

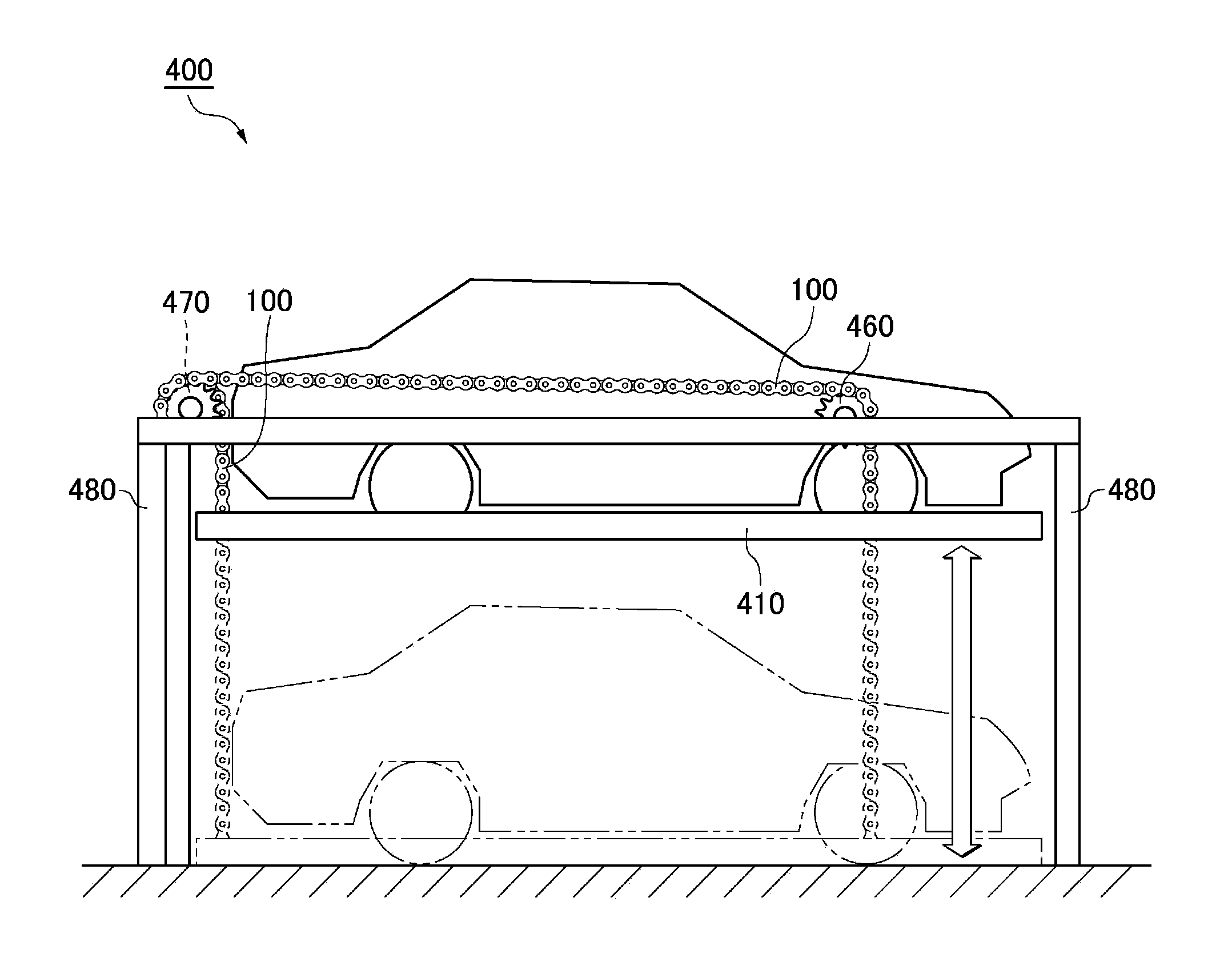

[0052] figure 1 It is a perspective view including a partial cross section of a suspension chain 100 according to the first embodiment of the present invention, figure 2 (A) is from figure 1 A top view of the suspension chain 100 according to the first embodiment of the present invention, which includes a partial cross section, seen from the direction of symbol 2A, figure 2 (B) from figure 1 A side view of the chain 100 for hanging according to the first embodiment of the present invention seen from the direction of symbol 2B, image 3 is used figure 1 A schematic side view of the three-dimensional parking lot 400 of the shown suspension chain 100, Figure 4 yes means image 3 A schematic perspective view of the installation of the hanging chain 100 of the shown three-dimensional parking lot 400, Figure 5 is used fig...

Embodiment 3

[0102] Below, refer to Figure 7 A suspension chain 300 according to a third embodiment of the present invention will be described.

[0103] here, Figure 7 (A) is a plan view including a partial section of a suspension chain 300 according to a third embodiment of the present invention, Figure 7 (B) is from Figure 7 (A) is a side view of the suspension chain 300 according to the third embodiment of the present invention seen from the direction of symbol 7B.

[0104] In addition, in order to facilitate the understanding of the invention, in Figure 7 (A) shows a partial section, but due to the Figure 7 In (B) it is not necessary to express a partial cross section without expressing a partial cross section.

[0105] The hanging chain 300 of the third embodiment is a structure in which the second link plate other than the outermost side of the hanging chain 200 of the second embodiment is replaced with the first link plate. The hanging chains 200 of the example are commo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com