Plate-shaped component connecting body, plate-shaped component connecting method, and image forming apparatus

A connecting body and component technology, applied in the field of image forming and drawing, can solve the problems of increased production cost, high-priced special fixtures, and many processes, and achieve the effect of low mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

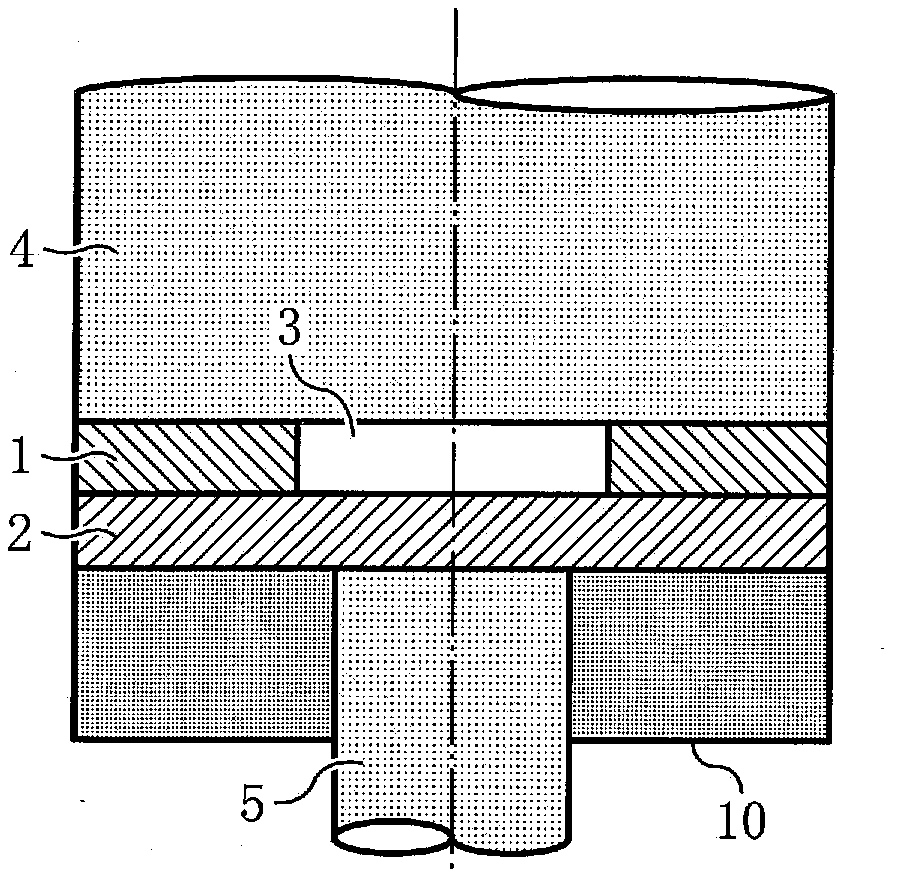

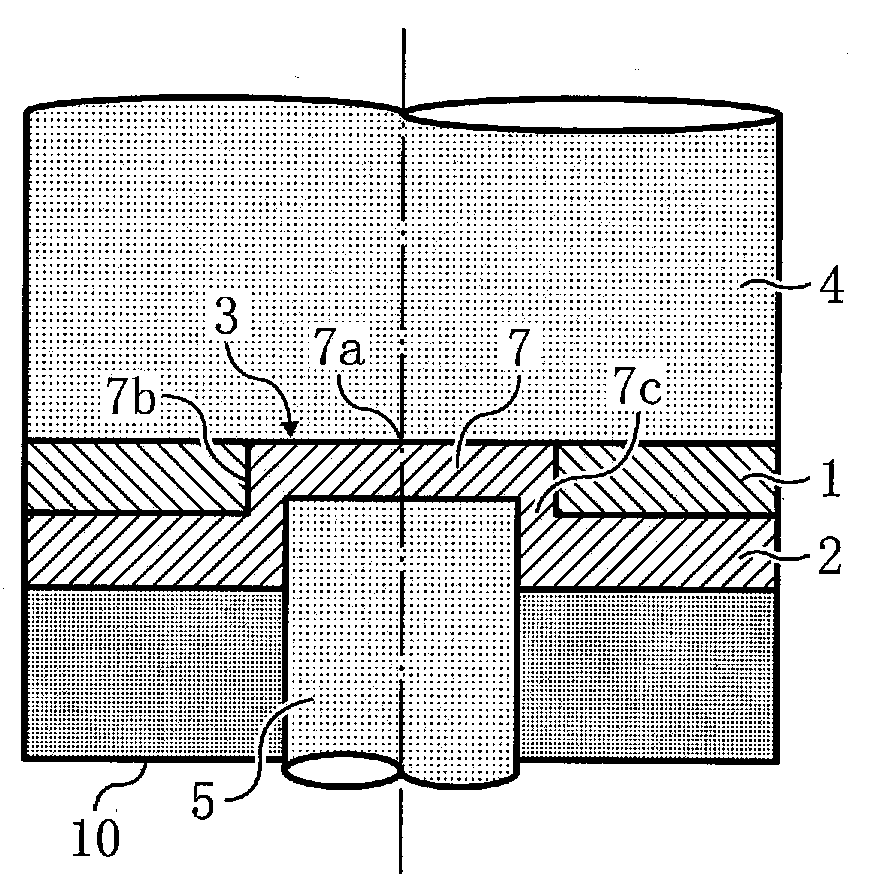

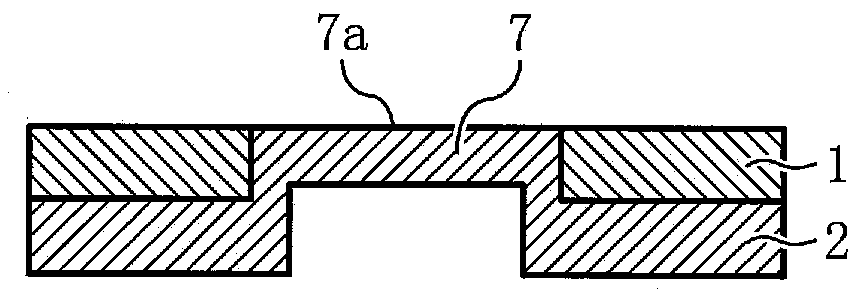

[0017] The present invention has the following features in terms of a method of connecting plate-shaped members. In short, in the present invention, the protrusions caused by plastic deformation protrude from the second plate-shaped member by pressing with the punch so as to fill the through-hole opened in the first plate-shaped member. Simultaneously, the material of the protruding part lost by the mold arranged to cover the surface of the through-hole of the first plate member flows in a direction away from the center of the through-hole, and the outer periphery of the protruding part engages with the inner wall of the through-hole, Only one process is used to connect the plate-like members. At this time, since the through hole is blocked by the filling of the protrusion, and the through hole is sealed by the mold, the protruding part of the protrusion cannot come out of the through hole on the side of the joined mold.

[0018] Embodiments of the present invention will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com