Ceramic organic composite binder for cubic boron nitride grinding wheels

A cubic boron nitride and ceramic composite technology, used in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of low grinding cost, unstable quality, low safety performance, etc., to maintain shape stability, improve, improve Macroscopic properties, the effect of improving anti-burn properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

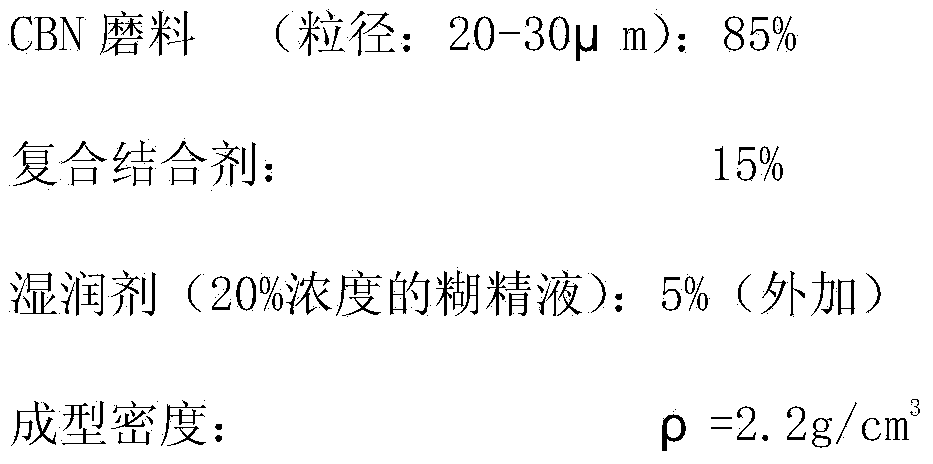

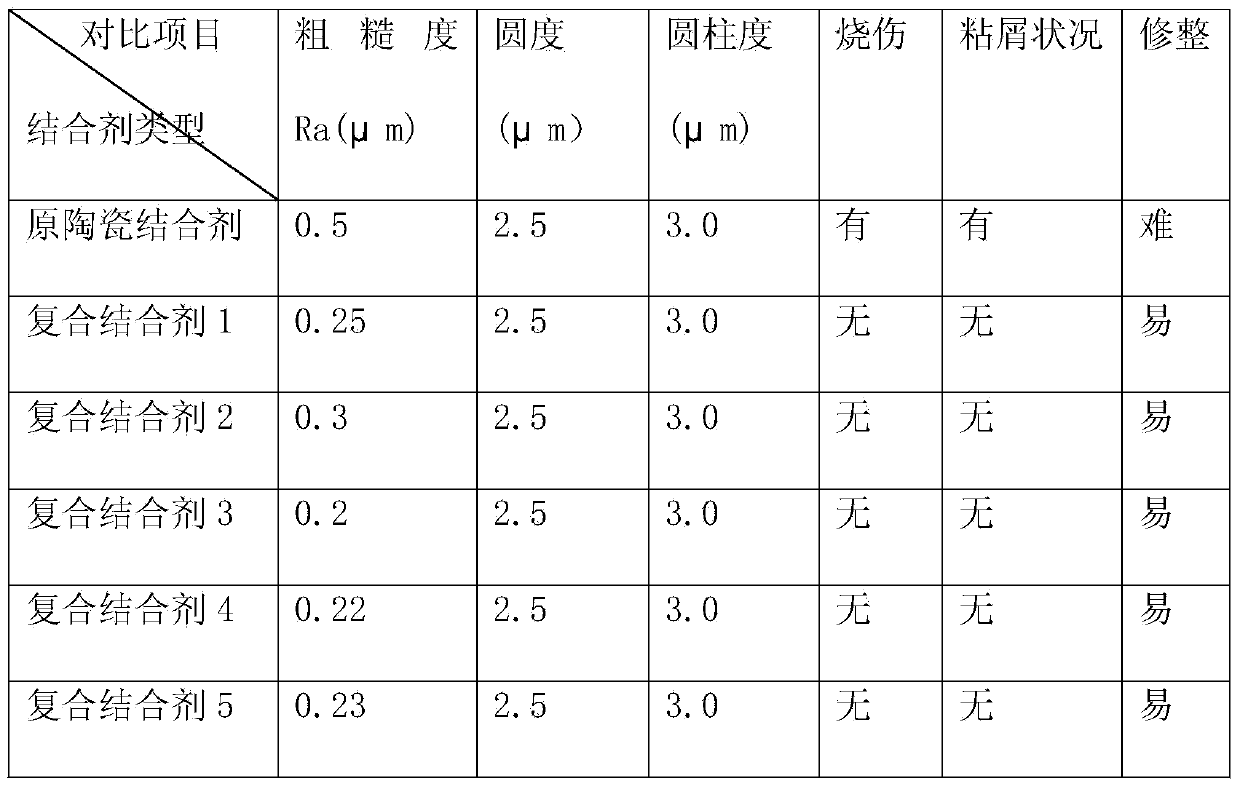

Embodiment 1

[0009] A vitrified composite binder for cubic boron nitride grinding wheels, which consists of the following raw materials in weight percent: aluminum phosphate AlPO 4 30%, tin dioxide SaO 2 8%, potassium feldspar 20%, albite 10%, titanium dioxide TiO 2 7%, boric acid 20%, silicon dioxide SiO 2 5%.

Embodiment 2

[0011] A vitrified composite binder for cubic boron nitride grinding wheels, which consists of the following raw materials in weight percent: aluminum phosphate AlPO 4 35%, tin dioxide SaO 2 7%, potassium feldspar 22%, albite 6%, titanium dioxide TiO 2 6%, boric acid 17%, silicon dioxide SiO 2 7%.

Embodiment 3

[0013] A vitrified composite binder for cubic boron nitride grinding wheels, which consists of the following raw materials in weight percent: aluminum phosphate AlPO 4 50%, tin dioxide SaO 2 5%, potassium feldspar 5%, albite 5%, titanium dioxide TiO 2 2%, boric acid 15%, silicon dioxide SiO 2 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com