Pneumatic hydraulic jack with no-load quick lift function

A pneumatic hydraulic jack technology, applied in the field of hydraulic jacks, can solve the problems of low work efficiency, waste of compressed air, slow rising speed, etc., and achieve the effect of improving work efficiency and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

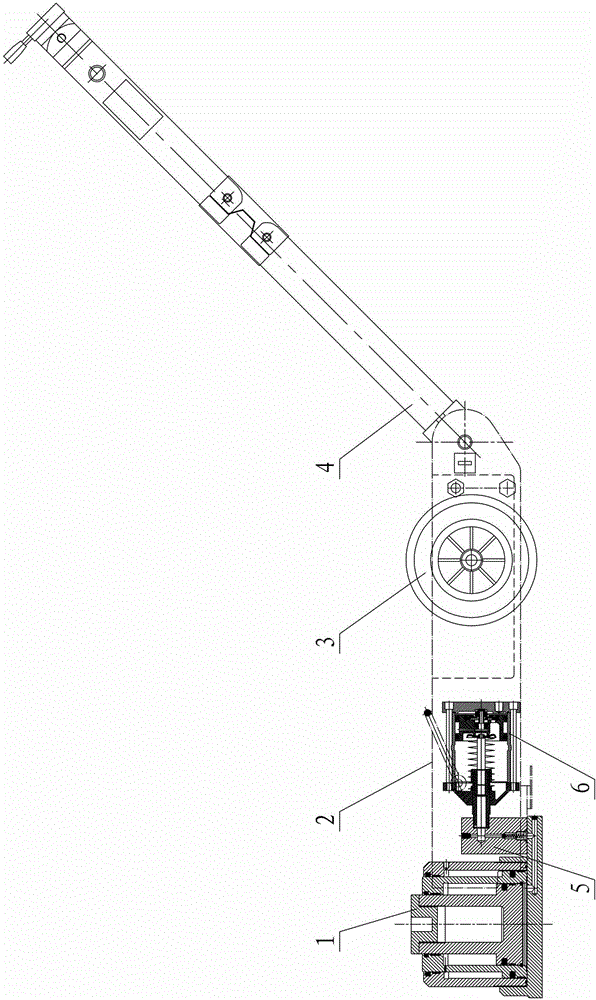

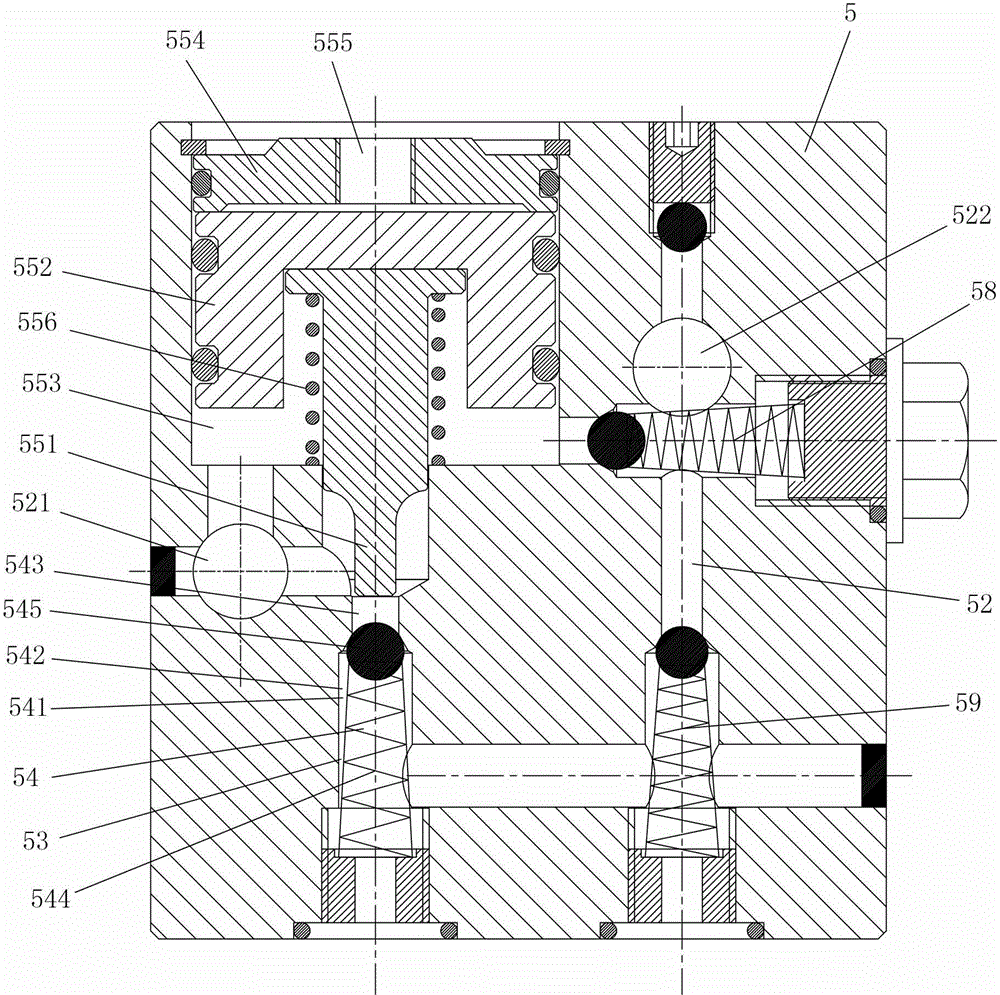

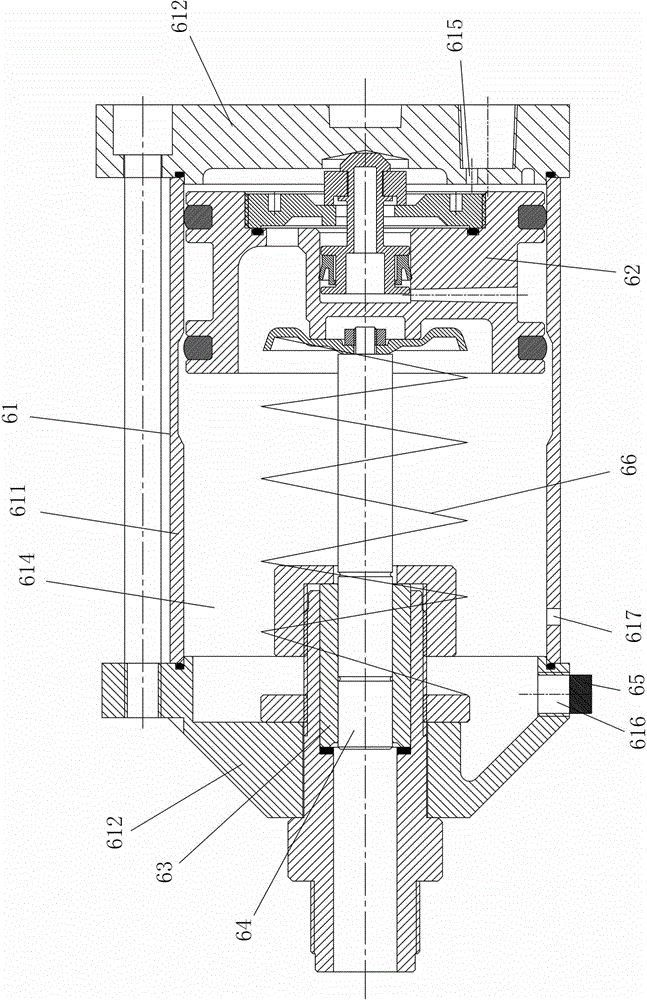

[0022] Such as figure 1 , figure 2 As shown, the pneumatic hydraulic jack with no-load fast lifting function of this embodiment includes a frame 2 and a fuel tank (not shown) installed on the frame 2, a lifting cylinder 1, a pneumatic booster 6, and wheels 3. , Operating lever 4 and transition plate 5. The operating rod 4 is mainly used for people to push the jack to walk, and the operating rod 4 is provided with switches and handles for controlling the start, stop, and lift of the jack. The oil tank is connected to the jacking cylinder 1 through the oil supply path 52 on the transition plate 5, and the hydraulic oil is pumped into the jacking cylinder 1 through the pneumatic booster 6 connected to the oil supply path 52. The oil supply path 52 is provided with a first check valve 58, a second check valve 59, an oil inlet pipe interface 521 for connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com