Shelf for automobile part transferring

A technology for auto parts and shelves, applied in the field of automobile processing, can solve the problems of complicated operation, difficult to move shelves, etc., to achieve the effects of low cost, difficult to move and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

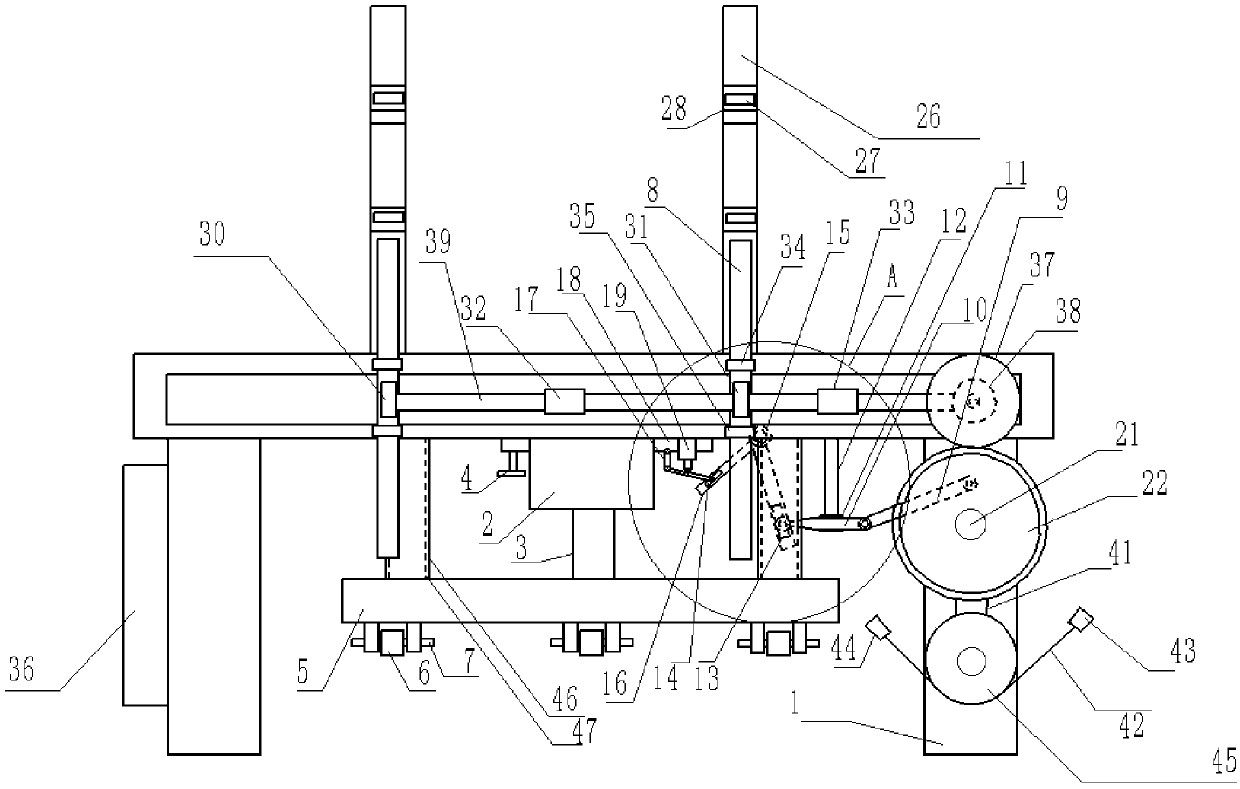

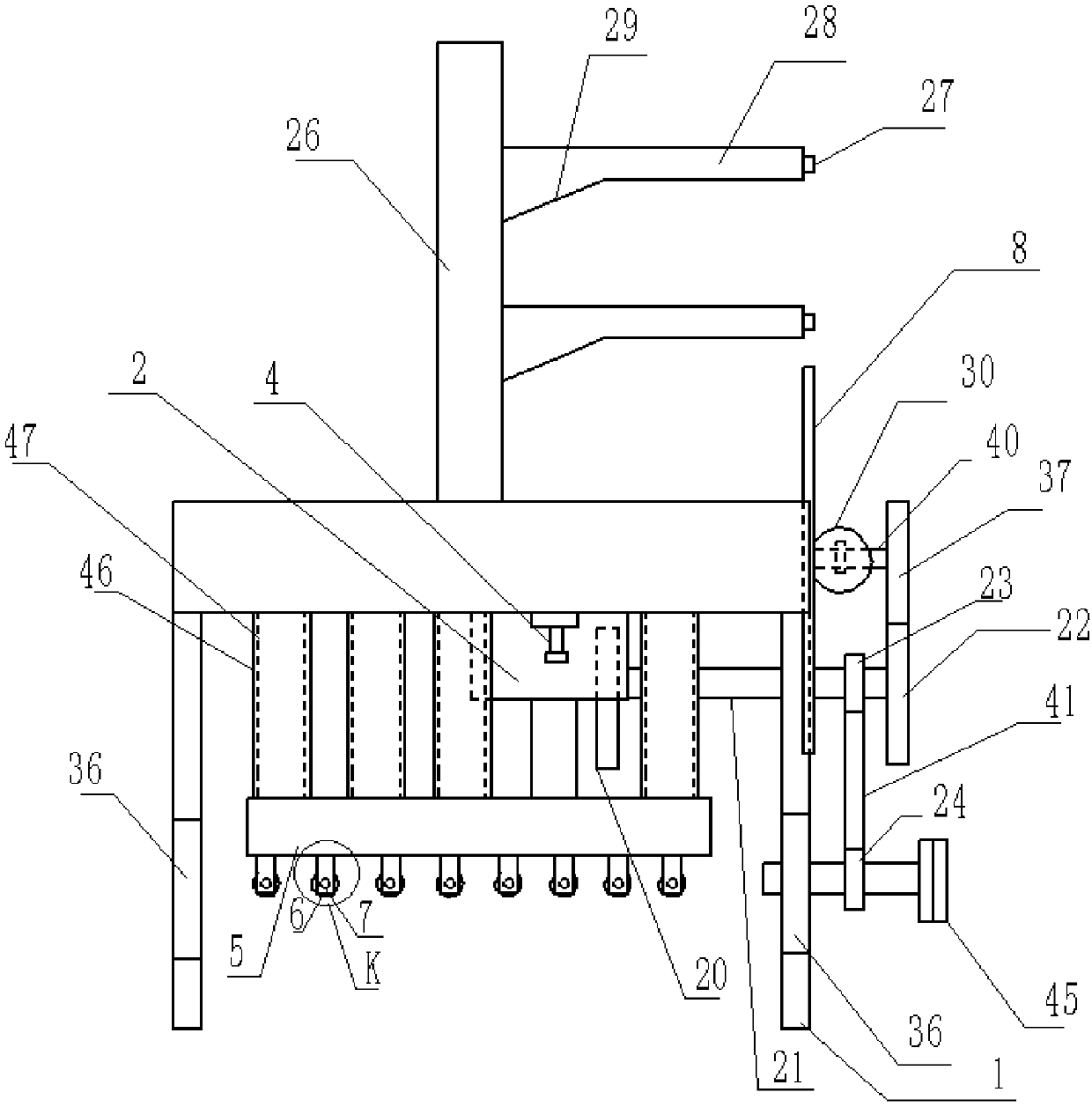

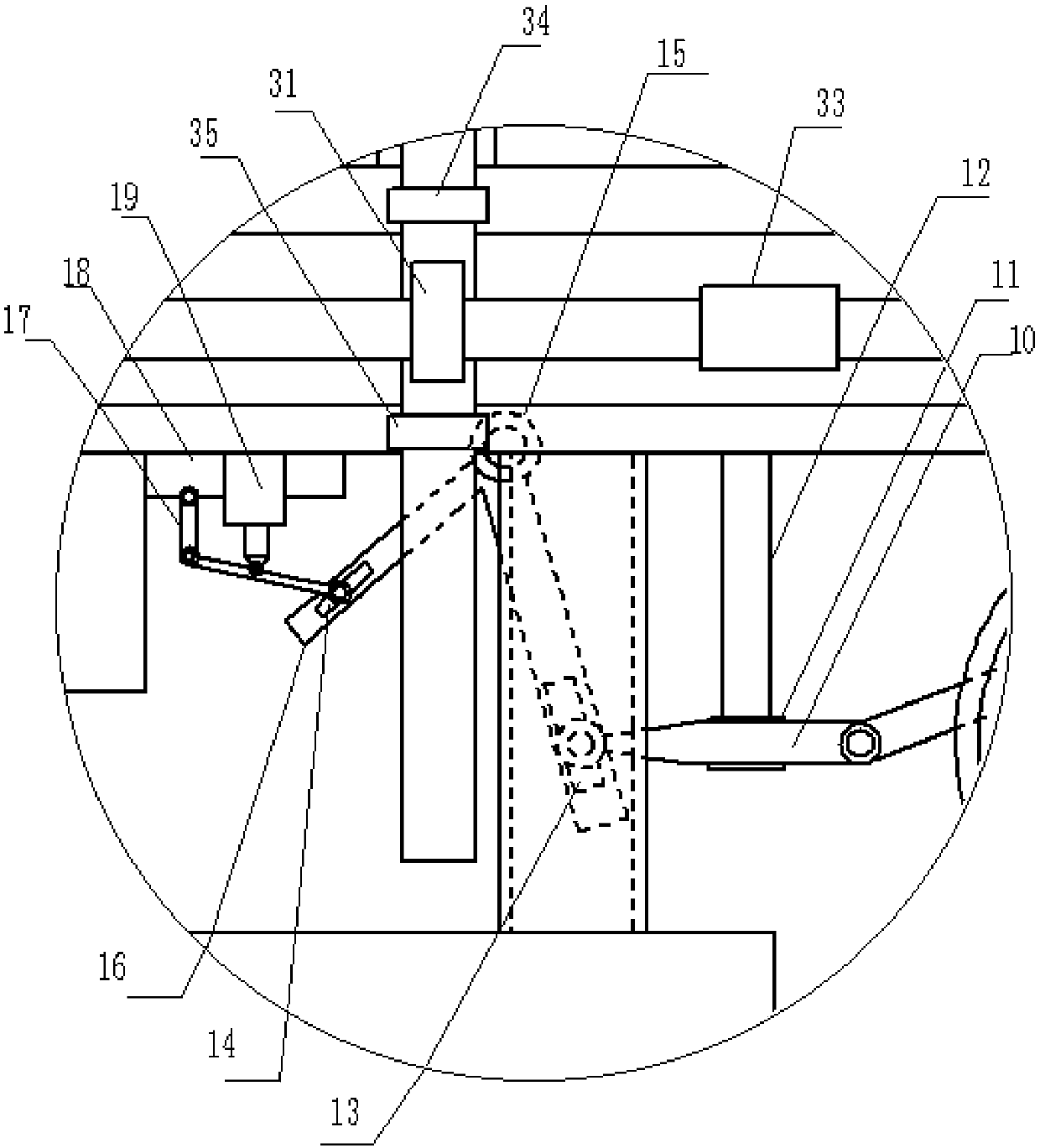

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 6 As shown, a simple auto parts storage shelf according to the present invention includes a shelf platform, a bracket is arranged above the shelf platform, and a support leg 1 is provided below the shelf platform, and the support leg 1 includes an extended support leg and a common support Legs, the lower middle part of the shelf platform is provided with a jacking device, the extended support leg on one side of the jacking device is provided with a power device and a jacking power conversion device, and the ordinary support leg on the other side of the jacking device is provided with a counterweight box 36 ; One side of the shelf platform is provided with a transmission device and a limit device; the power device is connected to the jacking power conversion device, the jacking power conversion device is connected to the transmission d...

Embodiment 2

[0042] On the basis of embodiment 1, independent scheme is:

[0043] A safe transfer shelf for auto parts, comprising a shelf platform, a bracket is arranged above the shelf platform, and a support leg 1 is arranged below the shelf platform, and the support leg 1 includes an extended support leg and a common support leg, and the extended support leg A power device and a jacking power conversion device are arranged on the top, a counterweight box 36 is arranged on the common support leg, and a transmission device and a limit device are arranged on one side of the shelf platform; the power device is connected to the jacking power conversion device, and the jacking power conversion device Connect the transmission device, and the transmission device is connected to the limit device;

[0044] Described power unit comprises first disk 45, and the circumference of first disk 45 is provided with a circle rope groove 50, and the elastic rope 42 that cooperates with rope groove 50, one ...

Embodiment 3

[0053] On the basis of embodiment 1, independent scheme is:

[0054] A shelf for auto parts transfer, including a shelf platform, a bracket is arranged above the shelf platform, and a support leg 1 is arranged below the shelf platform. The support leg 1 includes extended support legs and ordinary support legs. The lower middle of the shelf platform A jacking device is provided, and a power device and a jacking power conversion device are arranged on the extended supporting leg on one side of the jacking device, and a counterweight box 36 is arranged on the common supporting leg on the other side of the jacking device; the power device is connected to the jacking device. Power conversion device, the jacking power conversion device is connected to the jacking device;

[0055] Described power unit comprises first disk 45, and the circumference of first disk 45 is provided with a circle rope groove 50, and the elastic rope 42 that cooperates with rope groove 50, one end of elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com