Wire clamp retractable operating device

A technology of operating device and wire clamp, applied in the direction of overhead line/cable equipment, etc., can solve the problems of failing to reach the design value of sag, illegal operation by operators, and short wire tightening distance, etc. Quick to work, simple to construct effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

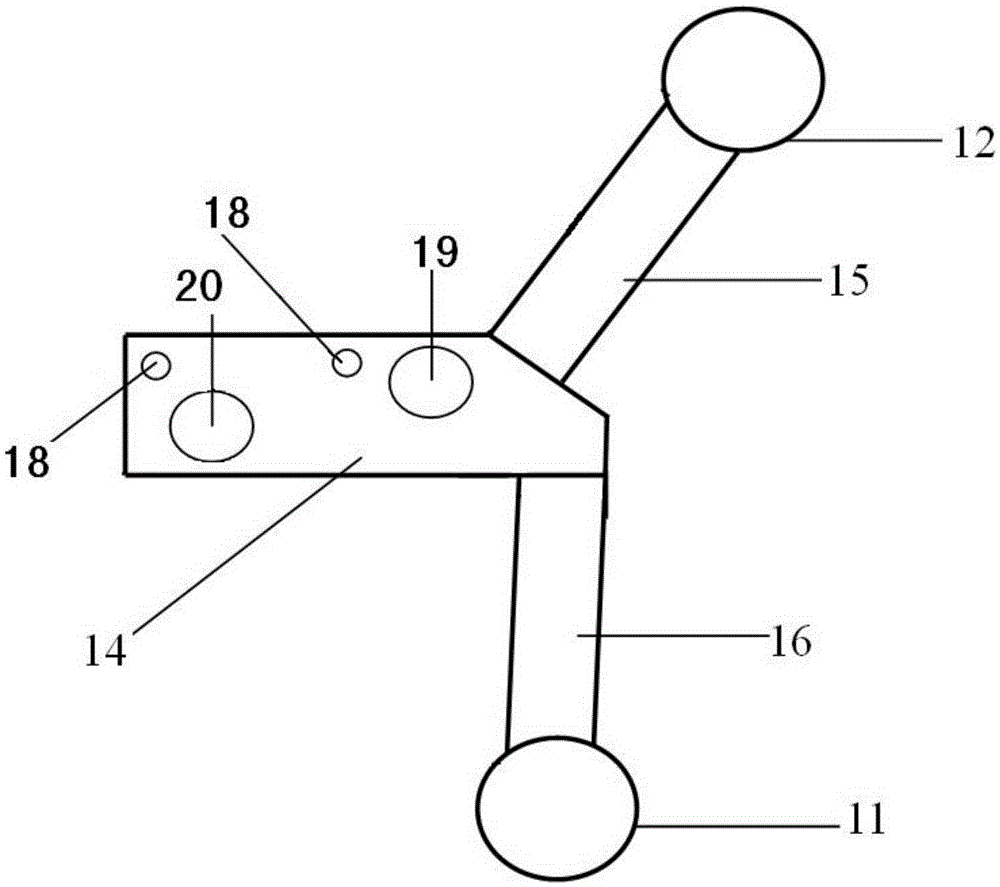

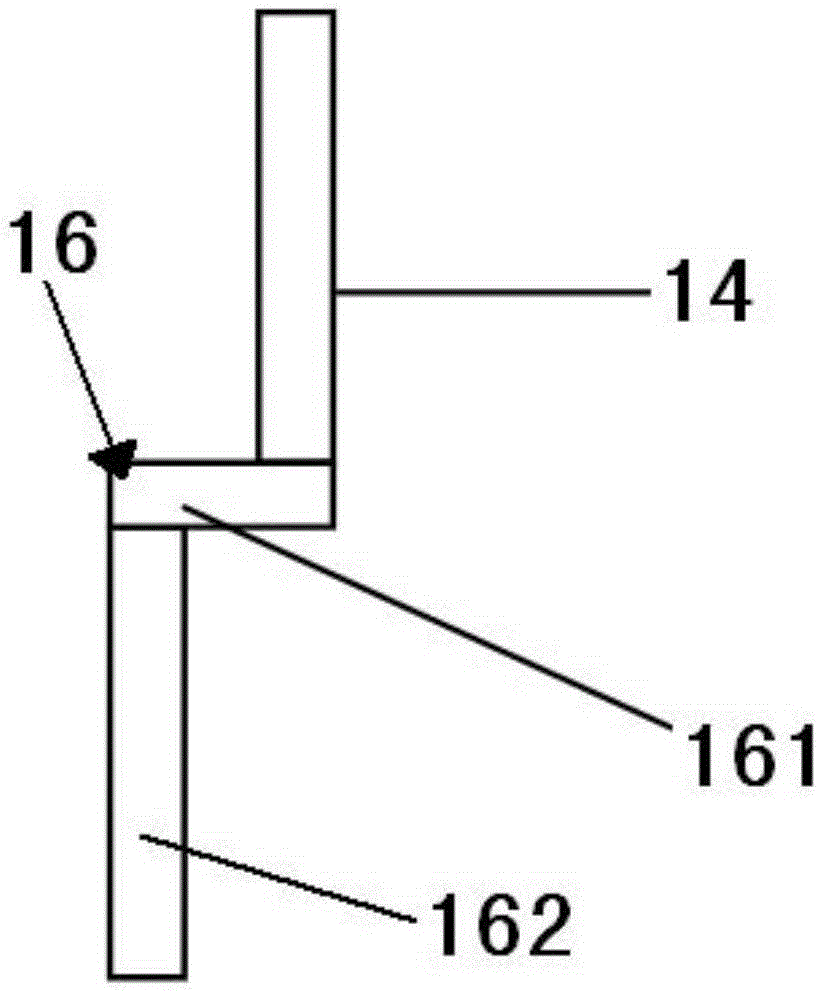

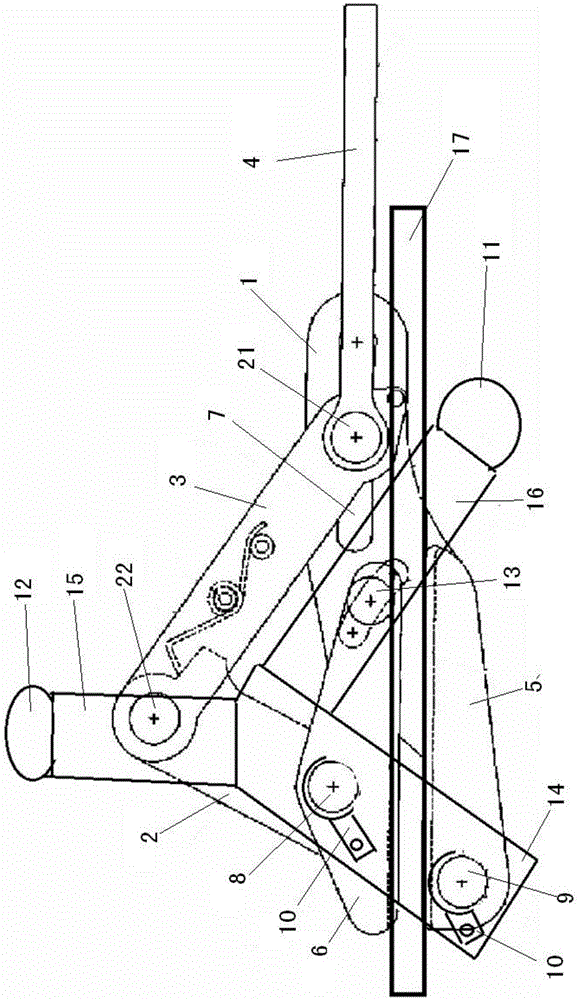

[0022] See attached Figure 1 to Figure 4 , the retractable operating device of the cable clamp, which includes a main connecting plate 14, a placing plate 15 and a recovery plate 16; the placing plate 15 and the recovering plate 16 are fixedly connected with the main connecting plate 14; the main connecting plate 14 is provided with two connecting holes 18 for connecting the safety hook 10, and for inserting the upper jaw fixing pin 8 so that the main connecting plate 14 can be connected with the upper jaw 6 of the wire clamp. Holes 19 and the second pin hole 20 for inserting the lower jaw fixing pin 9 so that the main connecting plate 14 can be connected with the lower jaw 5 of the cable clamp; One end of the plate 14 is provided with a placing pull ring 12 , and the end of the recovery plate 16 away from the main connecting plate 14 is provided with a recovery pull ring 11 .

[0023] The wire clamp includes a base plate 1 , a connecting plate 2 , a pull arm 3 , a pull ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com