Wiper arm having swivel cover allowing access to the head and pivot shaft

A wiper arm and wiper technology, which is applied in the directions of vehicle cleaning, transportation and packaging, vehicle maintenance, etc., can solve the problems of difficult removal, inadvertent removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

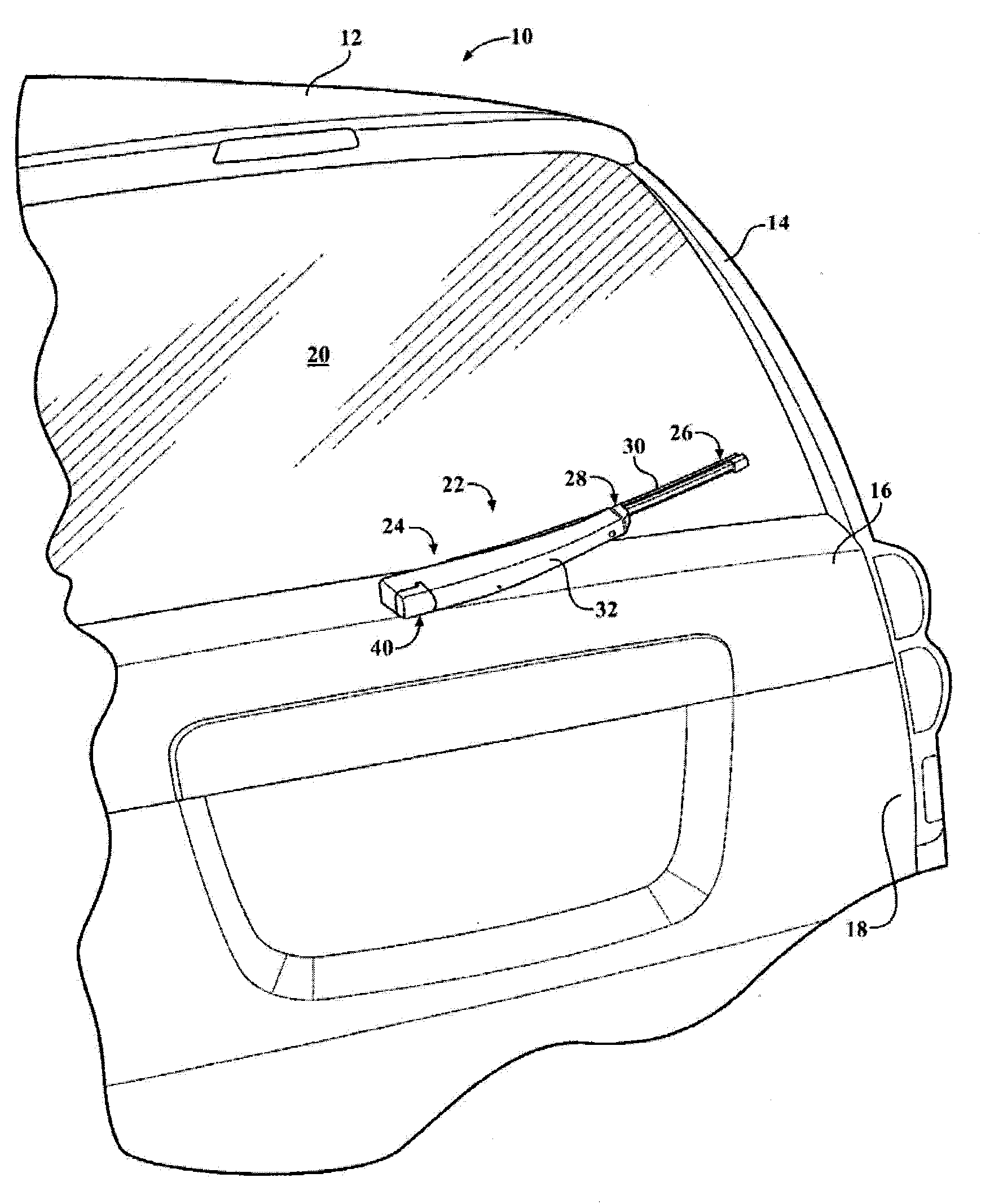

[0016] Referring now to the drawings, in which like numerals are used to indicate like structures, a portion of a vehicle is figure 1 is schematically shown at 10 . More specifically, the portion of the vehicle used to illustrate the invention includes a general illustration of the rear of the vehicle. Accordingly, the vehicle includes a roof 12, a pair of pillars 14 (in figure 1 Only one is shown), the liftgate 16 and the rear 18 of the vehicle. A rear glass window 20 extends between the pillars 14 on the liftgate 16 . While the present invention is shown with a liftgate 16 at the rear of the vehicle, those of ordinary skill in the art will understand from this description that the vehicle may include a hatchback configuration or any other configuration without departing from the scope of the present invention. other known configurations.

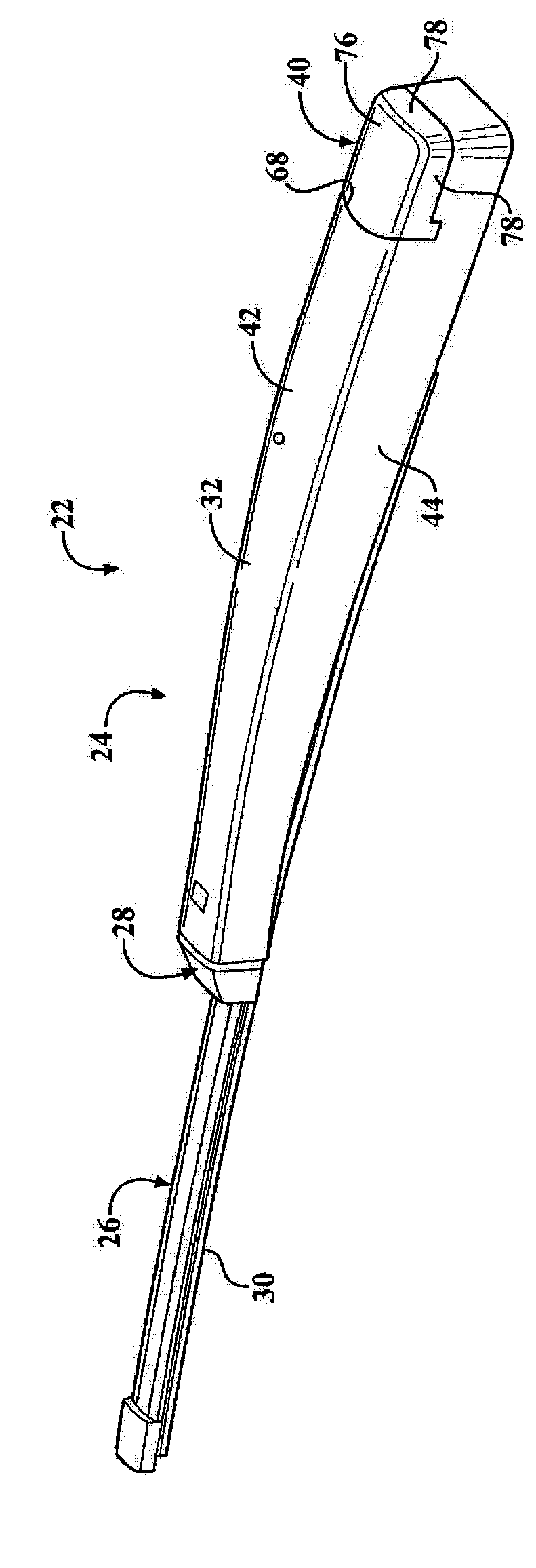

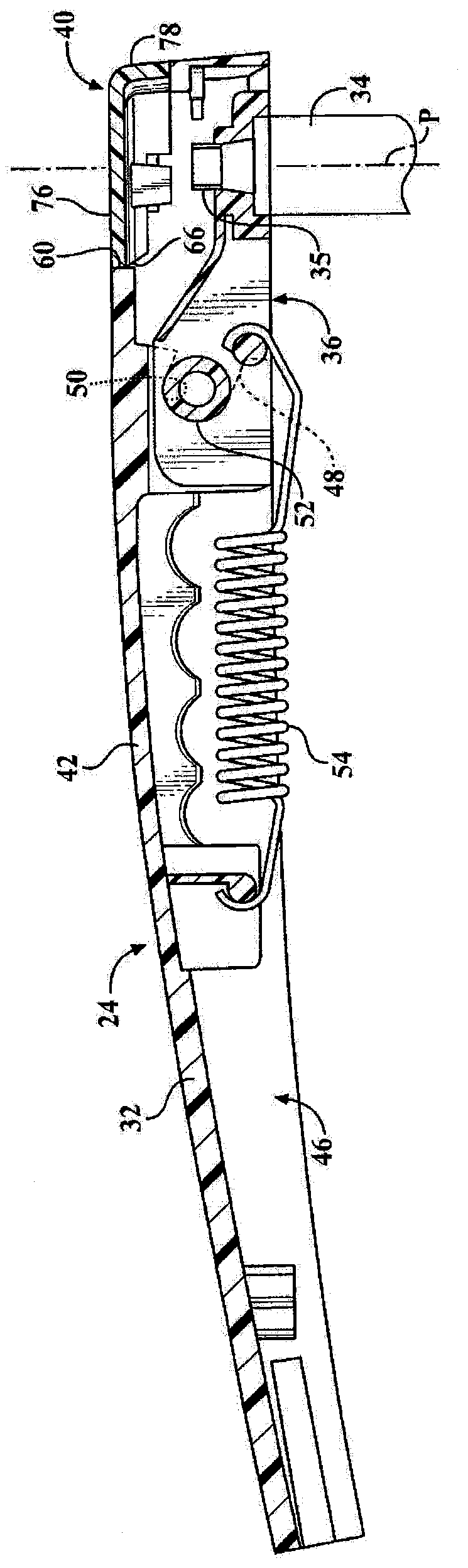

[0017] exist figure 1 A central wiper system is indicated generally at 22 and in the embodiment described here is used to clean the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com