Iron art modeling double-folding type dynamic skateboard made of metal round bars

A folding and wrought iron technology, applied in the field of entertainment products, can solve the problems of the inability to fold the vitality board, the small displacement of the 20,000-way wheels, and the unsatisfactory riding speed of the vitality board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

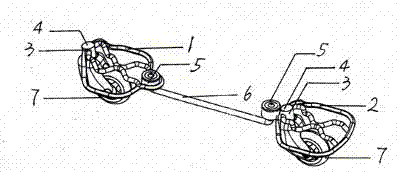

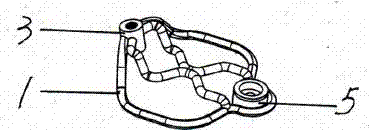

[0014] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the metal round bar material wrought iron shape double folding dynamic skateboard, including wrought iron molding front pedal 1, wrought iron molding rear pedal 2, screw barrel 3, screw barrel stuffy cover 4, rotating drum 5, connecting rod 6 and universal wheels 7;

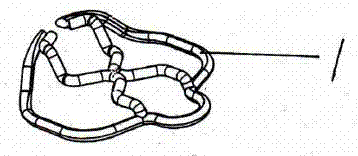

[0015] Described wrought iron forming front pedal 1 is to bend a metal round bar of 8 millimeters into a C-shaped frame, and there is a small semicircle-shaped bulge on the opposite side of the C-shaped opening on the C-shaped frame, and the described wrought iron forming front pedal 1. The inner diameter of the small semi-circle-shaped outer protrusion opposite the C-shaped opening on the C-shaped frame of 1 corresponds to the outer diameter of the metal tube ring of the drum 5, and is pressed into a convex angle with two 8 mm metal round rods. The two ends of two 8mm metal round rods with convex angles in the middle are welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com