An elastic resistance mechanical brake device

A technology of mechanical braking and elastic resistance, applied in transmission, gear transmission, transmission control, etc., can solve the problems of limited adaptability, high cost, rapid oil temperature rise, etc., and achieve reliable safety performance and adaptability. Wide and explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

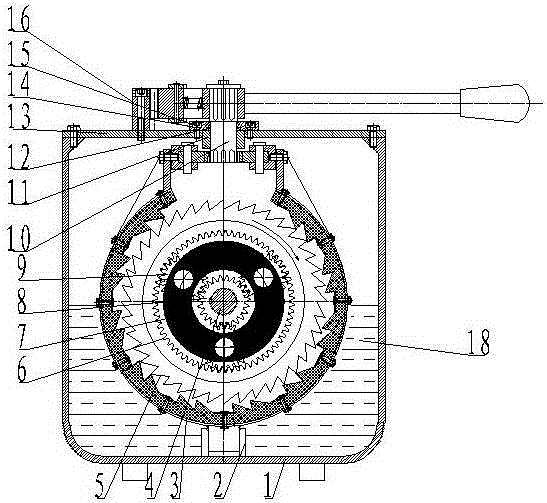

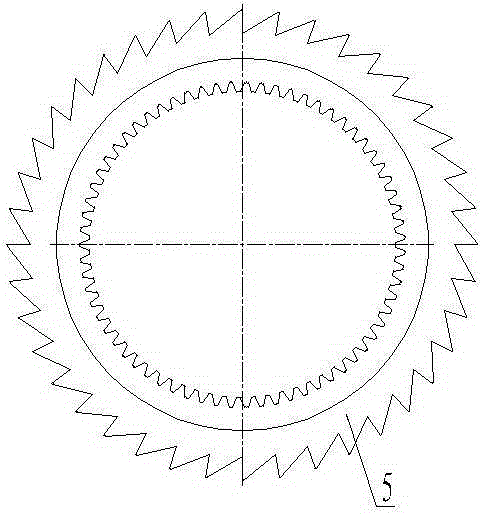

[0035] See attached figure 1 to attach Figure 8 , attached Figure 12, the elastic resistance mechanical braking device described in this embodiment includes an organic casing 1, a ratchet ring 3, a ratchet gear 5, a planetary transmission system, an operating device, and an eccentric locking device 10, wherein the planetary transmission system is assembled on In the casing 1, lubricating oil 18 is injected in the machine cavity of the casing 1; the planetary transmission system includes a power input shaft 4, a planetary ring gear 6, a planet carrier 7, a sun gear 8, and a planetary gear 9, wherein , the power input shaft 4 is assembled on one side of the planetary carrier 7, and the other side of the planetary carrier 7 is connected with the output shaft; the sun gear 8 is set on the power input shaft 4 and meshed with the planetary gear 9 installed in the planetary carrier 7, The planetary gear 9 is meshed with the planetary ring gear 6, and there are three planetary gea...

Embodiment 2

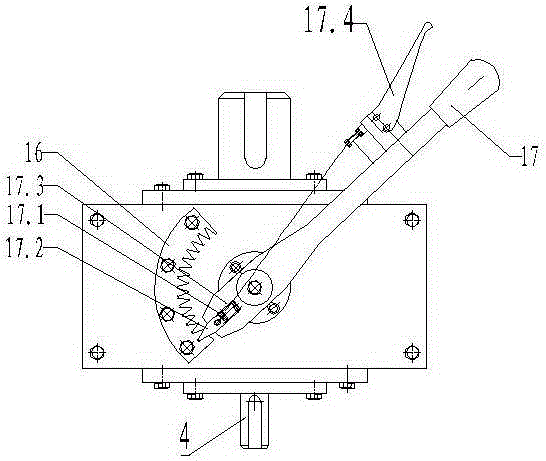

[0038] See attached Figure 9 To attach Figure 12 , the difference between this embodiment and Embodiment 1 is that the operating device is composed of a two-way hydraulic cylinder A9 and a hydraulic system A10, wherein the two-way hydraulic cylinder A9 is installed on the mounting seat, and the mounting seat is connected to both ends of the ratchet ring 3; the two-way The hydraulic cylinder A9 is connected to the hydraulic system A10 controlled by a proportional valve. The ratchet gear 5 is a compound wheel composed of outer ratchet teeth A5.1 and inner teeth A5.2, and the compound wheel is a structure designed by combining the ratchet gear and the inner ring gear. Ratchet ring 3 includes spring steel sheet A3.2, shrapnel A3.3, left locking support A3.4, right locking support A3.5, cam A3.6, third screw A3.7, installation Seat A3.8, wherein the spring steel sheet A3.2 is an arc-shaped mechanism, and a plurality of evenly distributed shrapnel A3.3 are punched on the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com